http://reprap.org/wiki/RepRap

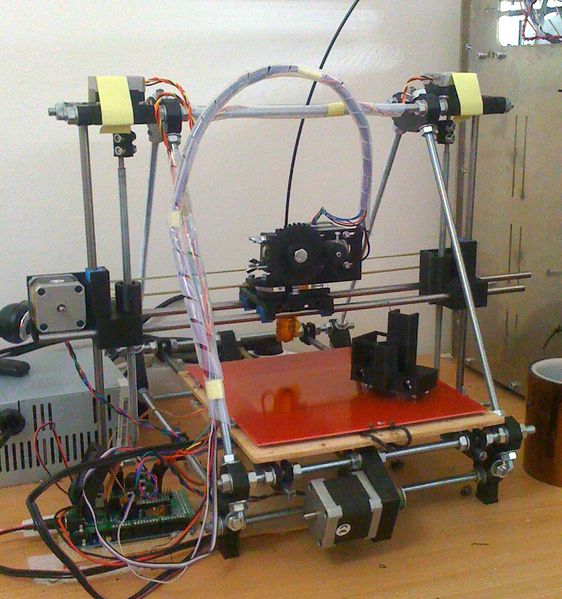

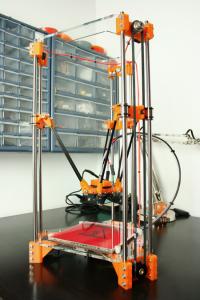

RepRap is a free desktop 3D printer capable of printing plastic objects. Since many parts of RepRap are made from plastic and RepRap can print those parts, RepRap is a self-replicating machine - one that anyone can build given time and materials. It also means that - if you've got a RepRap - you can print lots of useful stuff, and you can print another RepRap for a friend...

How does the Reprap machine work?

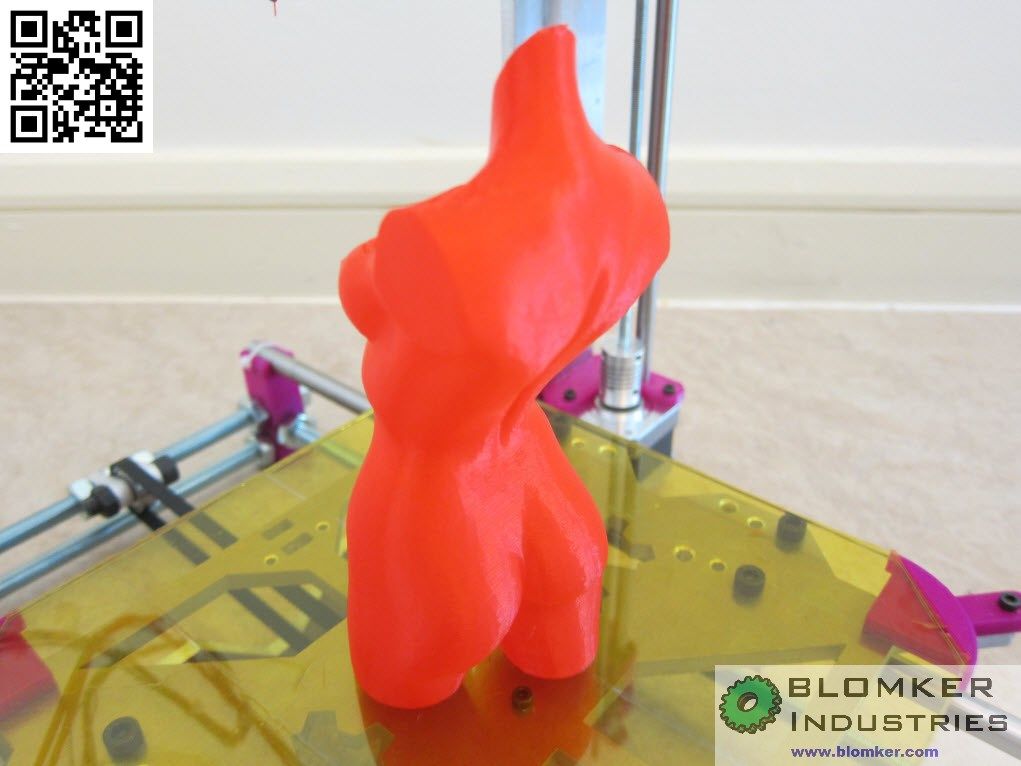

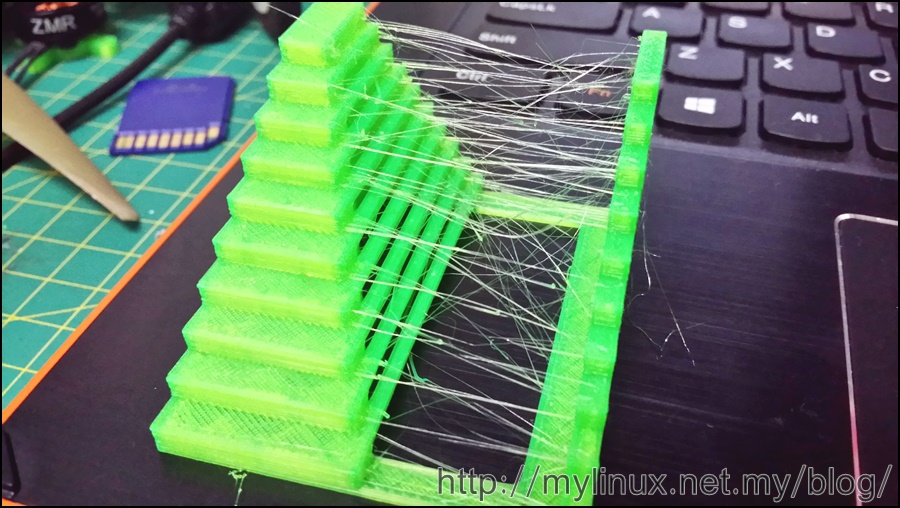

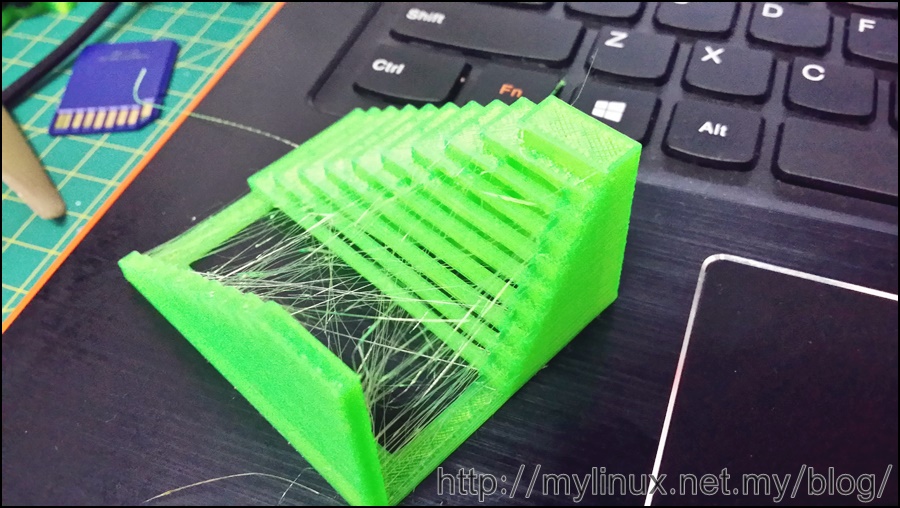

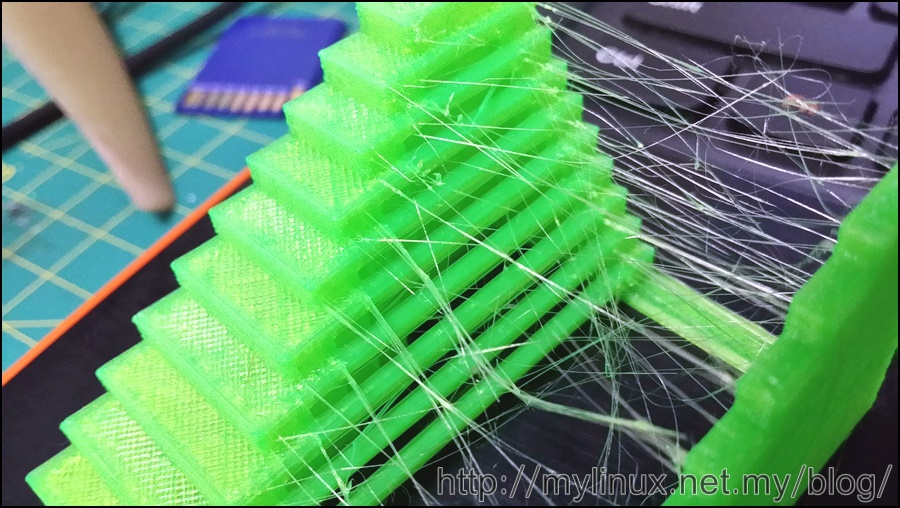

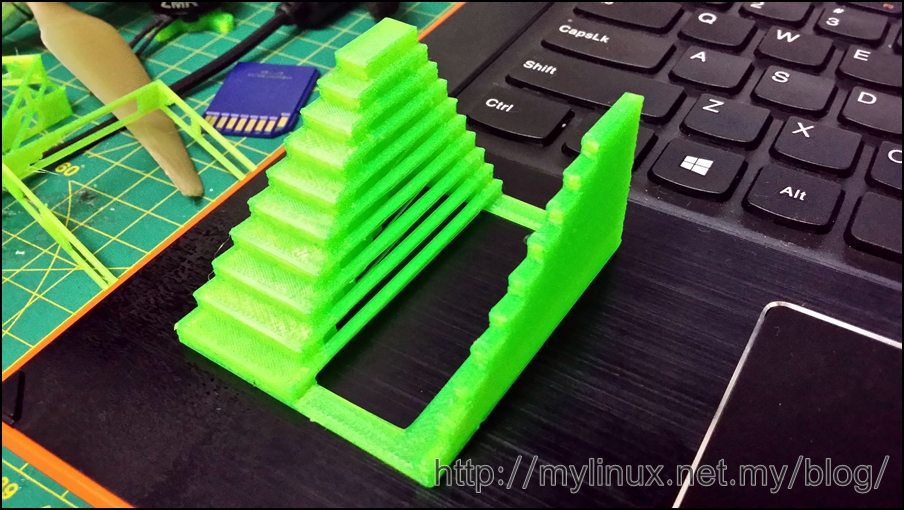

It’s a 3D printer, that is to say a computer controlled machine that can draw a highly intricate pattern and move up a fraction of a millimeter and draw another pattern. In this case instead of dispensing ink onto the paper, it uses a plastic extruder (think hot glue gun) into a flat surface until a very detailed 3D object is created. It is a critical machine in any manufacturing factory, or research and development lab.

Here is an excellent video from the Reprap founders showing how the Mendel Reprap works, worth the watch!-(http://www.youtube.com/watch?v=FUB1WgiAFHg) What is the point? The Reprap Project (www.reprap.org) envisions that 3D printing will be found in every home in the future. And will change the way goods are made. Instead of running to the shop every time you need a little trinket for one thing or another, you could likely make it at home and for less cost. For most homes, this is still a dream but with the help of the developer community the printer is constantly undergoing an evolution and learning how to print faster more precisely and with new materials. One day the machine will be able to print 100% of all its parts.

Okay, but why?

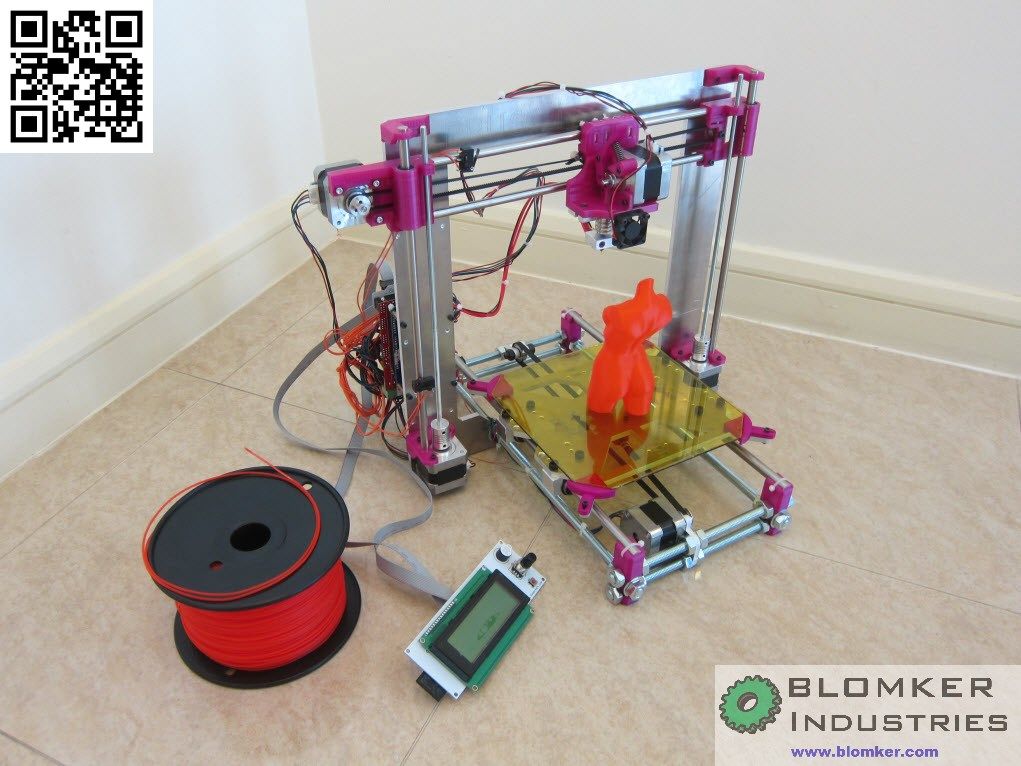

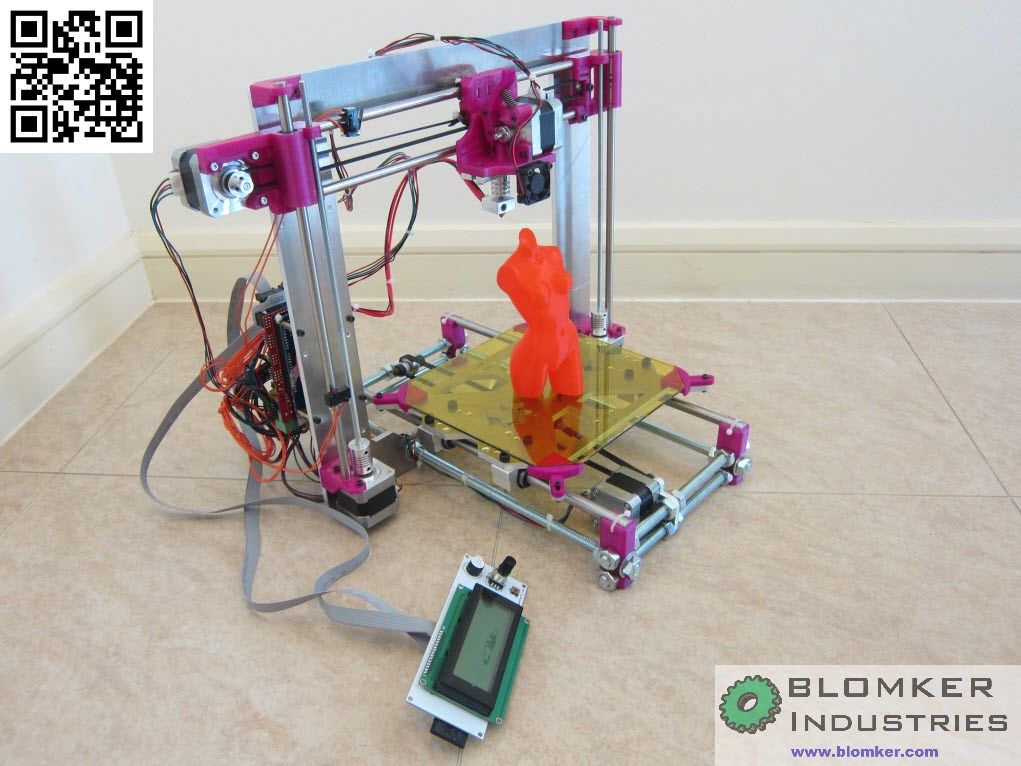

Well, first of all, it's cool as hell. Secondly, you can print more printers for fun (and profit!). Thirdly, you can print rather beautiful models and objects, properly configured, a reprap can print stuff that gives commercial printers that cost USD$10-30k a run for their money.

For example;

More at; http://www.thingiverse.com/

Whoa, those are beautiful, but how much will it cost?

Personally, I'll put the figure at somewhere around $600-800 USD from international sources, not including shipping and the time you'll take to put it all together. If you're resourceful and/or very good at hunting for cheap parts, you can bring that figure even lower.

I've built a Reprap Prusa Mendel before, and I'll be printing out a set of parts to put together another printer when I get back to Malaysia.

Added on March 5, 2012, 5:02 pmHmm.. since noone's posting I guess I'll share the research I've done so far. I've been looking around for the places to source the materials to put together a Reprap cheaply, and easily.

Basically, a reprap is split into two parts, the Printed parts and the Vitamins.

Printed parts are parts of the printer which can be printed on another printer, while vitamins are parts which can not. Motors, electonics, steel rods, etc.

Electronics

The most common electronics for repraps are either RAMPS or Sanguinololu. Kits can be found for about 50-60USD

RAMPS is more fully featured than Sanguinololu, but it's also more expensive, because it relies on an Arduino board (Which is another ~50-60USD on top of the board's price).

The prices above are for unassembled kits, which means you'll need to do your own soldering, if you're not up to that, you can get assembled ones for a premium.

On the boards sit 4-5x stepper drivers, and arguably the best stepper drivers you can get are Pololu's. (About $15USD each and you'll need at least 4)

The motors used for repraps are called Stepper Motors, which is different from DC motors which you find in your old Tamiya cars. The common size used is NEMA 17, and sometimes for the extruder, NEMA 14 motors are used to save weight. Most stores online sell these at 25USD each, and you'll need at least 5 of them for a Prusa Mendel.

Hotend

Arguably the most important part of the printer is the Extruder. This is where the plastic filament gets fed into the printer and hot molten plastic comes out that can then be formed into your objects. There are a number of commercial hotends available and here are a few of the popular ones;

Arcol: http://shop.arcol.hu/

Budaschnozzle: http://www.lulzbot.com/en/5-hot-ends

J-Head: http://hotends.com/ and http://www.emakershop.com/Seller=784

Makergear: http://www.makergear.com/products/operators-pack

Parcan: http://www.emakershop.com/Seller=59

The extruder is one of the parts of the printer which you won't be able to get much cheaper if you tried to assemble one yourself, unless you make it in large quantities. So it's cheaper (and easier!) to just get one of the popular ones.

Hardware

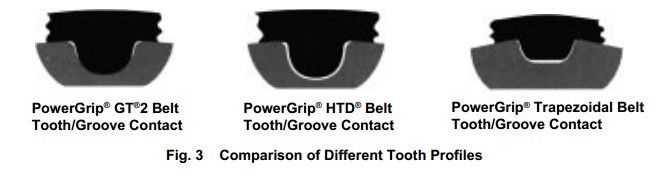

Belts and pulleys connect and drive the printer's X and Y axis. If you have an old printer that doesn't work anymore, you could probably rip it apart and salvage the timing belt and pulley found inside. Otherwise, try to get either T2.5, GT2 or MXL belts with a 2mm pitch. You'll need around 2m for both X and Y axis (1m for each) and don't worry, because it doesn't have to be a continuous loop. You can buy metal pulleys online, they're nice, but plastic pulley would work fine too, and they would be cheaper.

T5 belts can still be used, but they're now outdated by the finer toothed belts.

Nuts, bolts, 608zz bearings (Common skateboard bearings). We'll need a bunch of these, which I assume can be found easily in local hardware stores..

Stainless steel threaded rods (allthread) and smooth bars (Bar stock?) are the parts which I'm having trouble finding a source for in Malaysia, and would love to know where I can get them cheap-ish-ly.

Software

It's free. Nuff said.

vs

vs

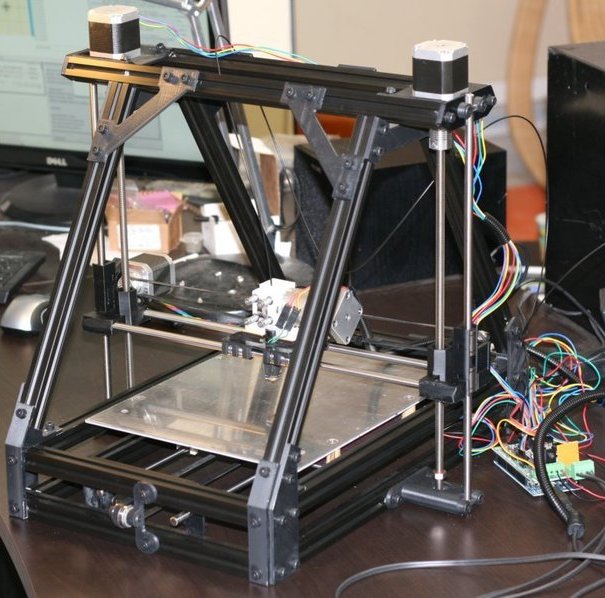

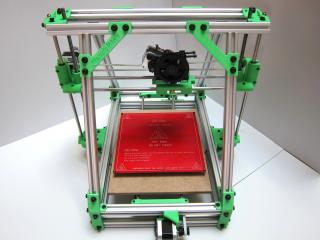

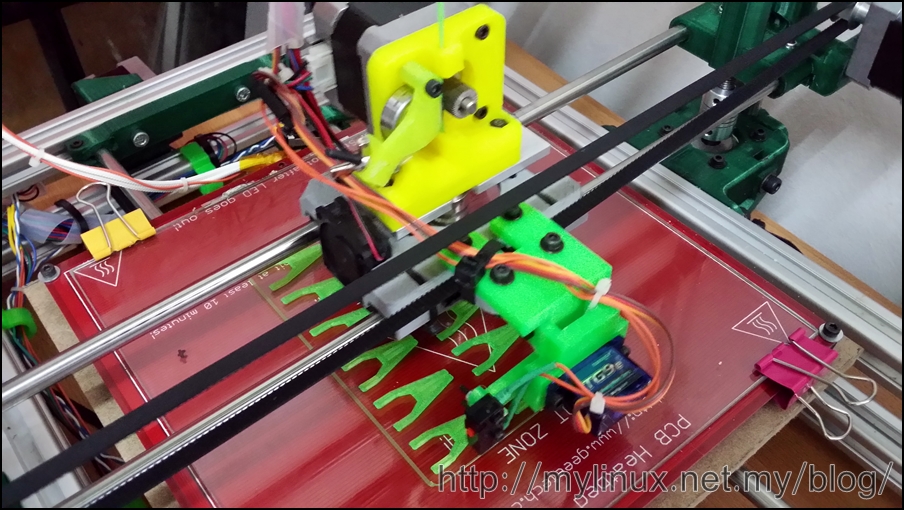

I figured I'd try to build a Mendelmax, which uses Aluminium T-Slot extrusions instead of the Prusa's rods, which gives it more stability and rigidity, allowing it to go faster and give better quality prints. (Although smooth rods and threaded rods are still needed.. advice on where to get them anyone?)

It's been recommended to get the extrusions from Misumi's website, and they've recently started a Malaysian branch! (Although the web ordering is stupid; fill in an excel spreadsheet and email it back to them for a quote?!). Unless anyone knows somewhere to get Aluminum extrusions cheap, I think that's where I'll be getting most of my hardware from. EDIT - Apparently only Misumi USA is willing to sell to individuals, hence, don't bother with the Malaysian branch.

This post has been edited by OoiTY: Mar 26 2012, 10:13 PM

Mar 2 2012, 12:27 PM, updated 14y ago

Mar 2 2012, 12:27 PM, updated 14y ago

Quote

Quote

0.3114sec

0.3114sec

0.64

0.64

6 queries

6 queries

GZIP Disabled

GZIP Disabled