QUOTE(daijoubu @ Jun 22 2012, 10:03 AM)

Didnt know there is a reprap thread in LYN! ^^

Good to see this, although its still pretty sparse, but Im sure more things will be up soon.

Hoping to see some other things such as T2.5 belts, etc.

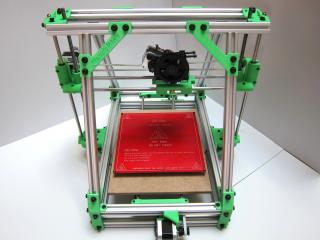

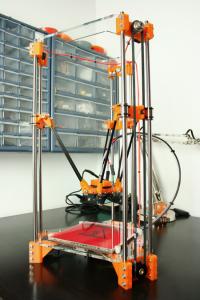

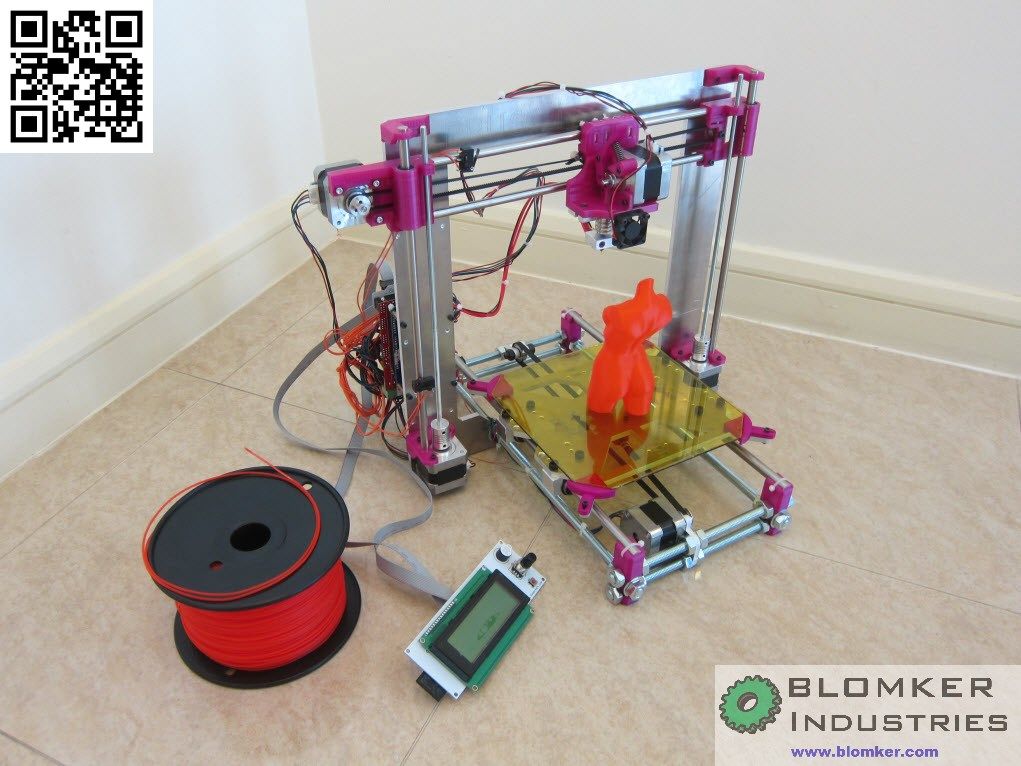

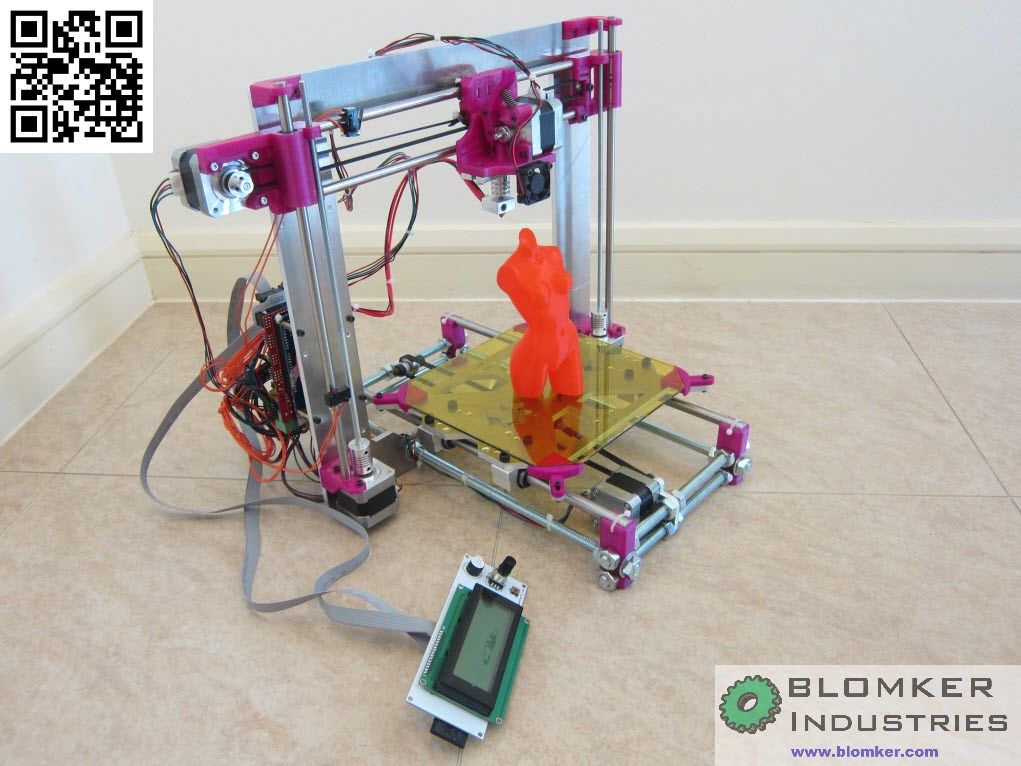

I've set up a Mendel kit i bought from Singapore 3 months ago. Took me 2 weeks to set it up. Managed to get movement in all axis, but before i could start setting up the software and calibrating, I had to leave on a business trip for 3 months. Until now the printer is still at home, waiting to be finished and start printing.

I've also already purchased the LM8UU bearings from China. Just waiting for the printer to start printing and I would upgrade parts to v2. Next step then would be to change the beltings. Both linear bearings and beltings contributes to the most improvement in quality of a print. Lastly I will consider to make a Ord typeprinter with aluminium extrusions =D.

Happy to see the scene in Malaysia is getting more crowded

. Hopefully this will encourage more local suppliers =D.

That's right. Everyone is so humble and secretive about their future shaping machine.

Glad to see another RepRap enthusiast reporting in.

Added on June 22, 2012, 9:53 pmQUOTE(storm88 @ Jun 22 2012, 11:11 AM)

Thanks

took some look into that imodela. It's a cnc milling platform isn't it? It's so small

talk about the DLP projected 3d printer,

After i had my machine implimented, i will get a hand into that to try it out. Just wonder what kind of mix the plastic Resin is. They don't reveal the formula yet ( i mean the designer)

Yup, that's a micro CNC mill selling for more than RM5k. Just mount a motor on your RepRap and it get transformed to a CNC mill as well.

I believe the photopolymer is the same type used for photolithography process in wafer fabrication. Anyone has contacts to wafer fab chemical supplier? Please report in yourself here.

Added on June 22, 2012, 9:54 pmQUOTE(voltro888 @ Jun 22 2012, 03:14 PM)

Now I can consider building one of these mean machine!

Hop in, buddy!

This post has been edited by blomker: Jun 22 2012, 09:54 PM

This post has been edited by blomker: Jun 22 2012, 09:54 PM

Jun 20 2012, 11:29 PM

Jun 20 2012, 11:29 PM

Quote

Quote

0.0397sec

0.0397sec

1.11

1.11

7 queries

7 queries

GZIP Disabled

GZIP Disabled