QUOTE(DarkTenno @ Jun 11 2014, 12:24 PM)

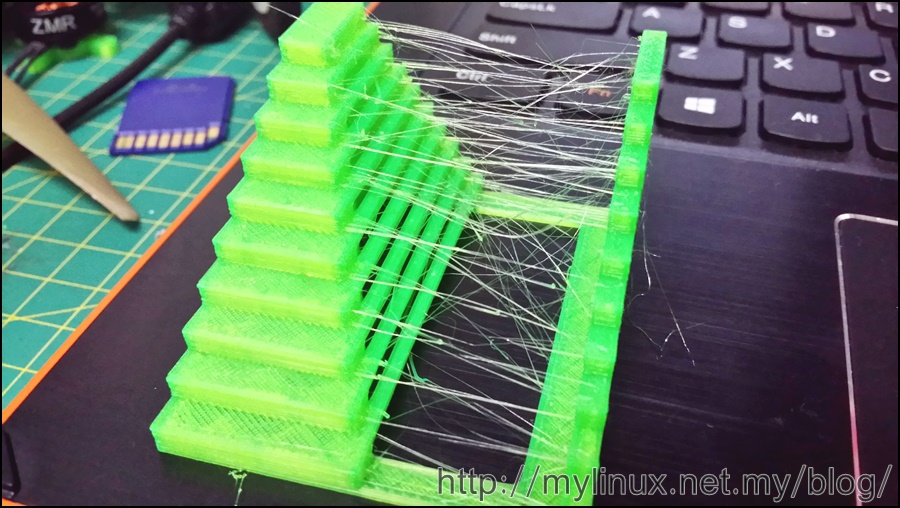

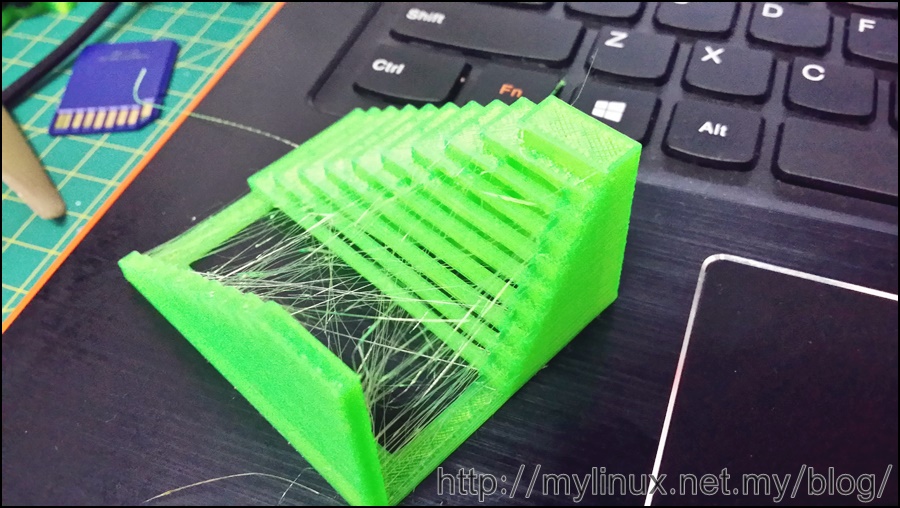

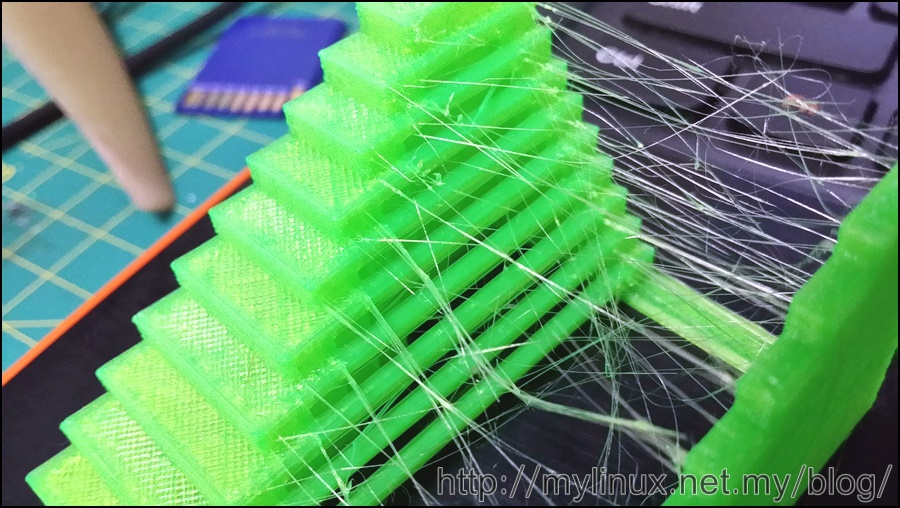

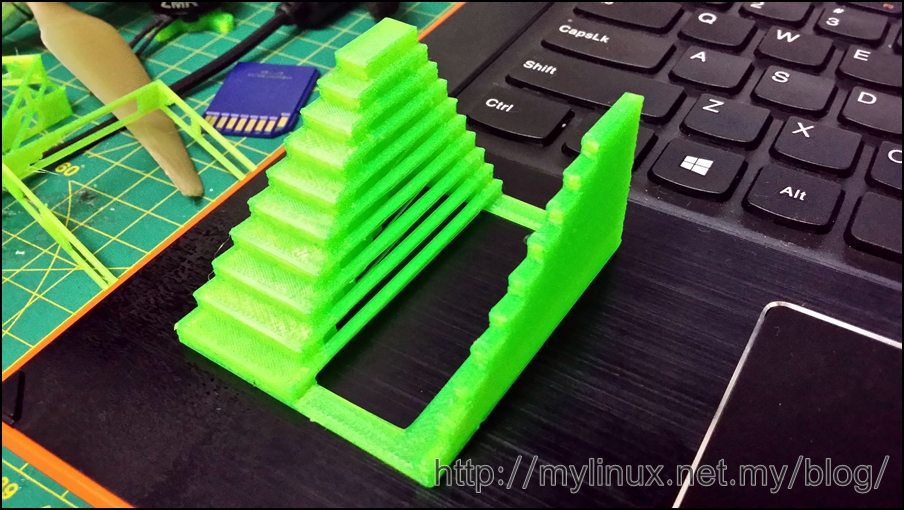

the more the merrier they said, still playing around with mine, print ok but some stringing/ozzing issues after updated my ramps to the latest marlin, need to do some calibration on the extruder

There are a few ways to solve stringing and oozing problems during prints.

First of all, you have to find the optimum set temp during print of the nozzle for your hotend which allows continuous uninterrupted extrusion and low oozing problems. For mine, I have set the initial first layer temp to 220 Deg C so I have reliable adhesion to the bed (non heated bed), then bring down the temp to 190 Deg after the first layer. For your case , you might try to warm the bed to 50 deg and print 190 through out the print.

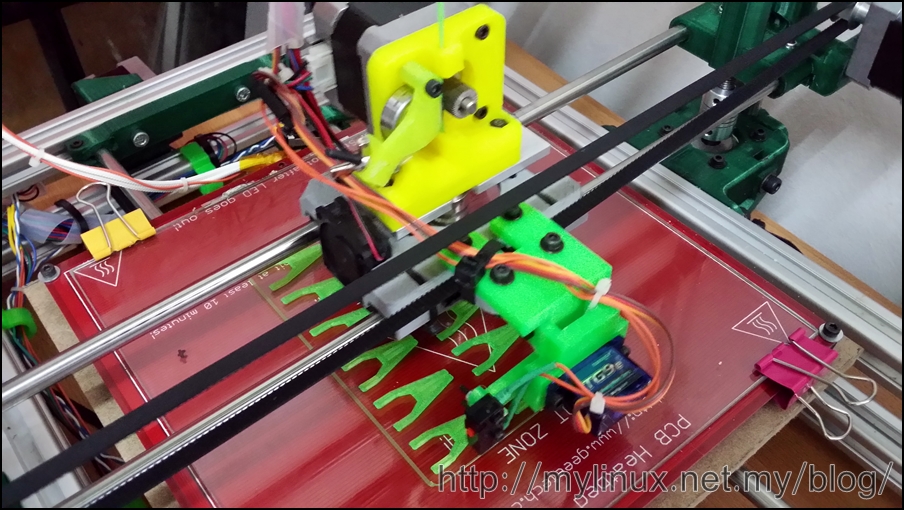

Secondly, after having another look at the the pictures of your hotend setup, if not mistaken, I can guess you have the fan pointing towards the PEEK section of your J-Head hotend. To solve the stringing issue/oozing issue, you might want to get another 12v fan or try to lower and tilt the existing fan towards the nozzle end. This is to allow rapid cooling of the extruded PLA when it is in contact with the print. Also, this helps with bridging, i.e. forming a bridge or mid air crossover between two section of a print. You might want to get a fan shroud from thingiverse,

http://www.thingiverse.com/tag:fan_shroud to focus the air flow towards the nozzle.

Oozing normally occurs when warming up the hotend but if its happening during prints then another way is to adjust the retraction rate in the slicer to minimize oozing. Stringing between gaps in prints is also affected by the retraction rate but these strings can be easily removed after the prints have complete.

QUOTE(DarkTenno @ Jun 11 2014, 12:24 PM)

btw any tips to switch bettween PLA and ABS for printing? need to print some ABS part for my printer

As for ABS, I have not tried ABS yet but from what I know, it is going to stink up your whole house with the smell of burning plastic. The hotbed temp has to be higher, about 100 deg and hotend should be about 220 deg for ABS but there are values recommended by ABS filament suppliers and you may have to adjust them around those values to work with your printer. Warping for ABS is a really big issue if your hotbed isn't set correctly but you can solve warping by turning on Brim support in your slicer.

Its good that there are people who can thinker and play around with their 3D printers as this is one of the ways to learn and master the technology.

Apr 12 2014, 12:22 PM

Apr 12 2014, 12:22 PM

Quote

Quote

0.0641sec

0.0641sec

0.14

0.14

7 queries

7 queries

GZIP Disabled

GZIP Disabled