Outline ·

[ Standard ] ·

Linear+

Repraps and DIY 3D Printing!, Open source hardware~

|

altan

|

Jan 6 2016, 06:26 PM Jan 6 2016, 06:26 PM

|

Getting Started

|

QUOTE(teohes @ Jan 6 2016, 05:38 PM) I met a guy selling that epoxy coating set for RM 90 during Comic Fiesta. I will send you his contact via PM if I can find his business card. |

|

|

|

|

|

teohes

|

Jan 7 2016, 09:46 AM Jan 7 2016, 09:46 AM

|

New Member

|

QUOTE(hihi @ Jan 6 2016, 10:49 PM) @hihi @altan, Thanks for the pointers ... will check it out. |

|

|

|

|

|

feiming

|

Jan 10 2016, 10:25 AM Jan 10 2016, 10:25 AM

|

Getting Started

|

QUOTE(hihi @ Jan 9 2016, 10:53 PM) Omg, short 10mm  I had the same problem.which was why I had to go buy extra smooth rod |

|

|

|

|

|

hihi

|

Jan 11 2016, 10:20 AM Jan 11 2016, 10:20 AM

|

Getting Started

|

QUOTE(feiming @ Jan 10 2016, 10:25 AM) I had the same problem.which was why I had to go buy extra smooth rod Made a brass connector to fix the rod to the frame. Having another problem yesterday, my lcd no display after connect to power supply, used few hours to figure out, need to update the firmware to make it work. |

|

|

|

|

|

altan

|

Jan 12 2016, 11:46 AM Jan 12 2016, 11:46 AM

|

Getting Started

|

QUOTE(hihi @ Jan 11 2016, 10:20 AM) Made a brass connector to fix the rod to the frame. Having another problem yesterday, my lcd no display after connect to power supply, used few hours to figure out, need to update the firmware to make it work. Got pic of the brass connector? If it was my case, I would 3D print a smooth rod holder instead  . OK, so the LCD is working now? BTW, very nice steel frame, I would have painted it...  The frame did not come warped? This post has been edited by altan: Jan 12 2016, 11:47 AM |

|

|

|

|

|

hihi

|

Jan 12 2016, 03:23 PM Jan 12 2016, 03:23 PM

|

Getting Started

|

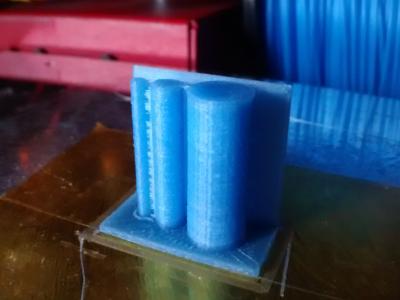

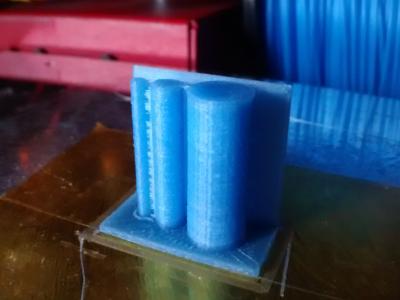

QUOTE(altan @ Jan 12 2016, 11:46 AM) Got pic of the brass connector? If it was my case, I would 3D print a smooth rod holder instead  . OK, so the LCD is working now? BTW, very nice steel frame, I would have painted it...  The frame did not come warped? Tonite i'll upload a brass connector picture. I made it using my mini lathe. Yes, the lcd is working now, now trying to configuration the marlin. Initially want to use sand paper to make it nice looking but very hard to sand. End up just grind the slug only. The plate came perfectly without warped. Brass Connector  This post has been edited by hihi: Jan 13 2016, 01:15 AM This post has been edited by hihi: Jan 13 2016, 01:15 AM |

|

|

|

|

|

altan

|

Jan 19 2016, 08:35 PM Jan 19 2016, 08:35 PM

|

Getting Started

|

Hey everyone, I am stocking and selling spare parts for RepRap printers. You can check it out at [WTS] 3D Printer & Reprap Parts / Accessories / Spare / Replacement Parts.Anyone interested can PM me and COD available around PJ area. This post has been edited by altan: Jan 19 2016, 11:46 PM Attached thumbnail(s)

|

|

|

|

|

|

hihi

|

Jan 23 2016, 11:31 PM Jan 23 2016, 11:31 PM

|

Getting Started

|

accidentally fried one of my A4988 stepper driver. I plug in reversely. Who got spare can sell me one?

|

|

|

|

|

|

altan

|

Jan 24 2016, 01:54 AM Jan 24 2016, 01:54 AM

|

Getting Started

|

QUOTE(hihi @ Jan 23 2016, 11:31 PM) accidentally fried one of my A4988 stepper driver. I plug in reversely. Who got spare can sell me one? I have both DRV8825 and A4988. I will PM you the price. This post has been edited by altan: Jan 24 2016, 01:54 AM |

|

|

|

|

|

hihi

|

Jan 26 2016, 10:23 AM Jan 26 2016, 10:23 AM

|

Getting Started

|

Having a hard time to level my printing bed. I level after put a 3mm glass. After 4 side leveled. Moved the noozle to center, and the noozle was touching the bed.

How should i overcome this problem?

|

|

|

|

|

|

altan

|

Jan 26 2016, 12:09 PM Jan 26 2016, 12:09 PM

|

Getting Started

|

QUOTE(hihi @ Jan 26 2016, 10:23 AM) Having a hard time to level my printing bed. I level after put a 3mm glass. After 4 side leveled. Moved the noozle to center, and the noozle was touching the bed. How should i overcome this problem? Should put a picture of your print bed so we get a better idea of your setup. Did you clamp down the glass sheet with binder clips? Is it a heated print bed and was the heater running? When you level the 4 corners , was the nozzle touching the bed without gap or small gap? This post has been edited by altan: Jan 26 2016, 12:49 PM |

|

|

|

|

|

hihi

|

Jan 28 2016, 11:57 AM Jan 28 2016, 11:57 AM

|

Getting Started

|

QUOTE(altan @ Jan 26 2016, 12:09 PM) Should put a picture of your print bed so we get a better idea of your setup. Did you clamp down the glass sheet with binder clips? Is it a heated print bed and was the heater running? When you level the 4 corners , was the nozzle touching the bed without gap or small gap? Manage to level the bed, did it after heat up the bed. Not perfectly but at least usable now. The different between side and center about 0.1mm different. Isolated the lower part of heat bed but unable to achieve110c for long time. Checked to voltage during heating only 10.5v. The bed resistant 1.7ohm. Tonite will try print abs using 105c. |

|

|

|

|

|

altan

|

Jan 28 2016, 12:11 PM Jan 28 2016, 12:11 PM

|

Getting Started

|

QUOTE(hihi @ Jan 28 2016, 11:57 AM) Manage to level the bed, did it after heat up the bed. Not perfectly but at least usable now. The different between side and center about 0.1mm different. Isolated the lower part of heat bed but unable to achieve110c for long time. Checked to voltage during heating only 10.5v. The bed resistant 1.7ohm. Tonite will try print abs using 105c. Alright, that is good. Since the difference is about 0.1mm I have a suggestion, you can set your first layer thickness to at least 0.2mm or more depending on nozzle size. By doing that there will be some squishing but that is fine as long as the first layer sticks to the bed. If the centre drops in/curve inwards, then need to relevel the Nozzle into the bed corners by 0.1mm to prevent lifting in the centre. |

|

|

|

|

|

feiming

|

Feb 5 2016, 03:41 PM Feb 5 2016, 03:41 PM

|

Getting Started

|

QUOTE(hihi @ Jan 26 2016, 10:23 AM) Having a hard time to level my printing bed. I level after put a 3mm glass. After 4 side leveled. Moved the noozle to center, and the noozle was touching the bed. How should i overcome this problem? i have this problem. I tried to change the glass to 6mm. I suspect it's the binder clip pressing too hard. I'm thinking to change to small clamp. That way i can control the clamping force. |

|

|

|

|

|

altan

|

Feb 5 2016, 04:52 PM Feb 5 2016, 04:52 PM

|

Getting Started

|

QUOTE(feiming @ Feb 5 2016, 03:41 PM) i have this problem. I tried to change the glass to 6mm. I suspect it's the binder clip pressing too hard. I'm thinking to change to small clamp. That way i can control the clamping force. Did you mean G clamps? Other solution is to 3D print ABS clips that will give just the right pressure. Finally my setup for ABS is a success but the prints are delaminating when bent along the layers for thin structures. I wasn't expecting 3D printed ABS to be inferior to PLA. Drillz included.

|

|

|

|

|

|

huiko12

|

Feb 13 2016, 02:03 AM Feb 13 2016, 02:03 AM

|

New Member

|

i'm intreasted to buy 3d printer ... should i start with prusa i3 (in mudah and lelong got 1)

|

|

|

|

|

|

altan

|

Feb 13 2016, 02:42 AM Feb 13 2016, 02:42 AM

|

Getting Started

|

QUOTE(huiko12 @ Feb 13 2016, 02:03 AM) i'm intreasted to buy 3d printer ... should i start with prusa i3 (in mudah and lelong got 1) The most budge friendly RepRap is still the Prusa i3. There are not many RepRap variants sold in Malaysia other than the Mendel, Rostock/kossel, and Prusa. On the other hand, if you have the budget for anything more than 2.5k then I would recommend getting a consumer 3D printer that's fully assemble (if you are not the adventurous type). Just note that a lot of these desktop 3D printer vary in price and the price absolutely does not guarantee reliablility. Even an expensive Makerbot can get jams and print issues compared to cheaper clones like the Flashforge for the same specs. My advice is to read up about 3D printers first or ask about other people experience before deciding on getting a 3D printer. If you just want to print a few things, then I would recommend using a 3D printing service as seen in my signature below.  This post has been edited by altan: Feb 13 2016, 02:44 AM This post has been edited by altan: Feb 13 2016, 02:44 AM |

|

|

|

|

|

huiko12

|

Feb 14 2016, 02:49 AM Feb 14 2016, 02:49 AM

|

New Member

|

@altan just wondering, will prusa i3 give the same quality as the consumer printer ?

|

|

|

|

|

Jan 6 2016, 06:26 PM

Jan 6 2016, 06:26 PM

Quote

Quote

0.0257sec

0.0257sec

0.17

0.17

6 queries

6 queries

GZIP Disabled

GZIP Disabled