I'm abit confused...

Can someone guide me, I need to DIY my ceiling light replacement....?

Wiring guide : 3 color wire (green, blue,black), Which one neutral, live and earth

Wiring guide : 3 color wire (green, blue,black), Which one neutral, live and earth

|

|

Jun 11 2011, 12:02 AM, updated 15y ago Jun 11 2011, 12:02 AM, updated 15y ago

Show posts by this member only | Post

#1

|

Junior Member

212 posts Joined: Sep 2010 |

I'm abit confused...

Can someone guide me, I need to DIY my ceiling light replacement....? |

|

|

|

|

|

Jun 11 2011, 12:06 AM Jun 11 2011, 12:06 AM

Show posts by this member only | Post

#2

|

|

Staff

25,802 posts Joined: Jan 2003 From: Penang |

Please do not DIY if you even not know how to differentiate green, blue and black in the first place.

Hire electrician to do the job, electricity can be dangerous, if not know to handle it. Standard Black - live Blue - neutral Green - earth. This post has been edited by cherroy: Jun 11 2011, 12:07 AM |

|

|

Jun 11 2011, 12:08 AM Jun 11 2011, 12:08 AM

Show posts by this member only | Post

#3

|

Junior Member

208 posts Joined: Apr 2009 |

green = ground

blue = neutral black/red = life most importantly the main switchbox is off n use test pen to detect any power leak... |

|

|

Jun 11 2011, 02:06 AM Jun 11 2011, 02:06 AM

Show posts by this member only | Post

#4

|

Senior Member

1,450 posts Joined: Oct 2008 |

QUOTE(cherroy @ Jun 11 2011, 12:06 AM) Please do not DIY if you even not know how to differentiate green, blue and black in the first place. Hire electrician to do the job, electricity can be dangerous, if not know to handle it. Standard Black - live Blue - neutral Green - earth. QUOTE(HarDiE @ Jun 11 2011, 12:08 AM) green = ground there is no fix standard on wiring color code, different country different std blue = neutral black/red = life most importantly the main switchbox is off n use test pen to detect any power leak... for single phase, normal 3 core wire: Brown=L Blue=N Green=E wire pull by electrician/ provided by developer: red/yellow/blue=L Black=N Green=E link:http://www.allaboutcircuits.com/vol_5/chpt_2/2.html This post has been edited by skng03: Jun 11 2011, 02:09 AM |

|

|

Jun 11 2011, 09:25 AM Jun 11 2011, 09:25 AM

Show posts by this member only | Post

#5

|

Junior Member

212 posts Joined: Sep 2010 |

QUOTE(skng03 @ Jun 11 2011, 02:06 AM) there is no fix standard on wiring color code, different country different std That's the confusing part...for single phase, normal 3 core wire: Brown=L Blue=N Green=E wire pull by electrician/ provided by developer: red/yellow/blue=L Black=N Green=E link:http://www.allaboutcircuits.com/vol_5/chpt_2/2.html red/yellow/blue=L Black=N or Blue=N Black=L |

|

|

Jun 11 2011, 09:44 AM Jun 11 2011, 09:44 AM

Show posts by this member only | Post

#6

|

Senior Member

1,529 posts Joined: Feb 2011 From: PJ |

1) Write down the colour code on existing connector

2) Check whether any indication there. 3) Normally Earth should be Green 4) Use Test Pen to check, if LIGHT UP meant is LIVE 5) The list one should then (without light up when use Test Pen) should be neutral * Please correct if wrong statement This post has been edited by Jo_da48: Jun 11 2011, 09:45 AM |

|

|

|

|

|

Jun 11 2011, 12:21 PM Jun 11 2011, 12:21 PM

Show posts by this member only | Post

#7

|

Senior Member

2,516 posts Joined: Feb 2007 From: Uarla Umpur |

most important is have a, working test pen...

and also some basic common sense... and ur all good to go |

|

|

Jun 11 2011, 07:27 PM Jun 11 2011, 07:27 PM

Show posts by this member only | Post

#8

|

Newbie

3 posts Joined: Jan 2009 |

for malaysian wiring colour code

Red/Yellow/Blue - Live Black - Neutral Green - Ground/earth. but for electrical appliances (plug/fluorescent fitting) it's depend on the country of origin.. it's a little bit different like. Brown/red - Live Blue/black - Neutral green - ground. This post has been edited by wannur: Jun 11 2011, 07:28 PM |

|

|

Jun 11 2011, 11:45 PM Jun 11 2011, 11:45 PM

Show posts by this member only | Post

#9

|

Senior Member

1,450 posts Joined: Oct 2008 |

|

|

|

Jun 12 2011, 09:58 AM Jun 12 2011, 09:58 AM

|

Senior Member

4,233 posts Joined: Jan 2003 From: Selangor |

what i do is use a test pen to find the live wire

|

|

|

Jun 12 2011, 12:25 PM Jun 12 2011, 12:25 PM

|

Junior Member

212 posts Joined: Sep 2010 |

|

|

|

Jun 13 2011, 11:28 PM Jun 13 2011, 11:28 PM

|

Junior Member

316 posts Joined: Apr 2005 |

easy rules:

Earth= always green Neutral= No colour, ie black or white Live= Coloured except green! the different colour of live wire used by the electrician is to differentiate type, zone etc... |

|

|

Jun 21 2011, 11:56 PM Jun 21 2011, 11:56 PM

|

Junior Member

212 posts Joined: Sep 2010 |

QUOTE(ryansia @ Jun 13 2011, 11:28 PM) easy rules: Thanks all for the help. I "survived" and successfully installed my ceiling light via DIY.Earth= always green Neutral= No colour, ie black or white Live= Coloured except green! the different colour of live wire used by the electrician is to differentiate type, zone etc... Very helpful information, indeed! mywife liked this post

|

|

|

|

|

|

Jun 22 2011, 09:22 AM Jun 22 2011, 09:22 AM

|

Senior Member

1,818 posts Joined: Jan 2005 From: Kuala Lumpur |

Good thread indeed. Last time, I tried to install my own lamp, just 1 lamp (the wiring is there already, hanging on the ceiling), i googled around and it's very confusing but i managed to do it ..

|

|

|

Jun 22 2011, 12:20 PM Jun 22 2011, 12:20 PM

|

Senior Member

3,173 posts Joined: May 2007 |

for lamp fittings, Neutral and Live is not important. Both connected to the terminals anyway. Just make sure the earth wire is not connected to one of the terminals or the Live not connected to the metal body...

|

|

|

Jun 24 2011, 06:55 PM Jun 24 2011, 06:55 PM

|

Junior Member

75 posts Joined: Mar 2009 |

who suggest replace a light need to hire a electrical man?? so malaysian... lols..

replace the light is js a piece of cake la, even ah poh can do that. most important is don't forget to switch off the power first. |

|

|

Sep 8 2014, 06:03 PM Sep 8 2014, 06:03 PM

|

Senior Member

519 posts Joined: Jun 2011 |

Reviving an old thread to get advice from sifus.......

I jut bought bout 3 dozen lights for new house, mostly ceiling mounted led panels. The shop's installer say standard rate is RM15 to install one light. I reckon each job will require : 2 screws to fit light to ceiling, connect 2 wires, pop the cover back. Most of the ceiling is plaster ceiling board. Drilling not a problem. So I am thinking to DIY myself. Before I fried myself or burn a row of houses, can sifus check if I got the theory part right : Most of my lighting points like this :    Q1 The middle wire can be red, yellow or blue. I think this is the wireman's way to identify each 'loop' Correct? Q2 So the Black = Neutral; Red/Yellow/Blue = Live; Green is Earth. Correct?  Q3 The LED lights has 2 tiny blue wires. These are to be connected to the Neutral (Black) and Live (R/Y/B) Which way also OK. Correct? Q4 No need to use Earth (Green) wire. Correct ah? Q5 There are two black and green wires each because of looping. Just leave them alone. Don't pull out. Correct? This post has been edited by Fazab: Sep 8 2014, 06:14 PM |

|

|

Sep 8 2014, 08:20 PM Sep 8 2014, 08:20 PM

|

All Stars

17,021 posts Joined: Jan 2005 |

QUOTE(Fazab @ Sep 8 2014, 06:03 PM) Reviving an old thread to get advice from sifus....... Q1 = that is live wire. Not loop. And probably a 3phase wire. Which each color represent R, S, T. I jut bought bout 3 dozen lights for new house, mostly ceiling mounted led panels. The shop's installer say standard rate is RM15 to install one light. I reckon each job will require : 2 screws to fit light to ceiling, connect 2 wires, pop the cover back. Most of the ceiling is plaster ceiling board. Drilling not a problem. So I am thinking to DIY myself. Before I fried myself or burn a row of houses, can sifus check if I got the theory part right : Most of my lighting points like this :    Q1 The middle wire can be red, yellow or blue. I think this is the wireman's way to identify each 'loop' Correct? Q2 So the Black = Neutral; Red/Yellow/Blue = Live; Green is Earth. Correct?  Q3 The LED lights has 2 tiny blue wires. These are to be connected to the Neutral (Black) and Live (R/Y/B) Which way also OK. Correct? Q4 No need to use Earth (Green) wire. Correct ah? Q5 There are two black and green wires each because of looping. Just leave them alone. Don't pull out. Correct? Q2 = correct. Q3 = if the wire have same color, that mean no polarity. Which way also can. Q4 = if your downlight casing is metal, you need to ground it. In case the light short and somebody touch it. Q5 = correct. If you pull out, others light will not light. |

|

|

Sep 8 2014, 08:45 PM Sep 8 2014, 08:45 PM

|

All Stars

11,308 posts Joined: Feb 2008 |

how you guys connect the wires together?

using those terminal blocks http://www.mdnsupplies.co.uk/shop/terminal-block-lg.jpg or these electrical caps? http://hostedmedia.reimanpub.com/TFH/Proje...U_WIRCON_01.JPG This post has been edited by idoblu: Sep 8 2014, 08:48 PM |

|

|

Sep 8 2014, 08:51 PM Sep 8 2014, 08:51 PM

|

All Stars

17,021 posts Joined: Jan 2005 |

QUOTE(idoblu @ Sep 8 2014, 08:45 PM) how you guys connect the wires together? Can be say, all the local using terminal block. using those terminal blocks http://www.mdnsupplies.co.uk/shop/terminal-block-lg.jpg or these electrical caps? http://hostedmedia.reimanpub.com/TFH/Proje...U_WIRCON_01.JPG Most of the western is using cap. But I using molex connector. |

|

|

Sep 8 2014, 08:54 PM Sep 8 2014, 08:54 PM

|

All Stars

11,308 posts Joined: Feb 2008 |

QUOTE(ozak @ Sep 8 2014, 08:51 PM) Can be say, all the local using terminal block. molex needs special crimping tool right but for lights is okay, i guessMost of the western is using cap. But I using molex connector. terminal blocks - i scared it melts and the two terminal touch. caps - i dont know if it will work or come loose for big gauge wire and one small wire (like you connect those drivers to existing wiring) i guess needs to get the correct size cap which i do not know how to determine any advice? This post has been edited by idoblu: Sep 8 2014, 08:57 PM |

|

|

Sep 8 2014, 08:59 PM Sep 8 2014, 08:59 PM

|

All Stars

12,019 posts Joined: Jan 2003 |

QUOTE(idoblu @ Sep 8 2014, 08:45 PM) how you guys connect the wires together? Terminal block good for simple and low current usage equipments like light and fan. High current stuff I use solder and shrink tapes.using those terminal blocks http://www.mdnsupplies.co.uk/shop/terminal-block-lg.jpg or these electrical caps? http://hostedmedia.reimanpub.com/TFH/Proje...U_WIRCON_01.JPG |

|

|

Sep 8 2014, 09:06 PM Sep 8 2014, 09:06 PM

|

All Stars

12,019 posts Joined: Jan 2003 |

Hard to reach area caps are good. If high current use caps need to be careful may burn if not properly screw, loose connection will cause heat=burn=fire.

|

|

|

Sep 8 2014, 09:07 PM Sep 8 2014, 09:07 PM

|

All Stars

17,021 posts Joined: Jan 2005 |

QUOTE(idoblu @ Sep 8 2014, 08:54 PM) molex needs special crimping tool right but for lights is okay, i guess Molex connector are more secure and can run higher amp. Can plug/unplug without switch off. No wrong connection pluging since it have a 1way connect. But yes, it need tool to clamp. terminal blocks - i scared it melts and the two terminal touch. caps - i dont know if it will work or come loose for big gauge wire and one small wire (like you connect those drivers to existing wiring) any advice? Terminal block have been using for very longtime. If the wire size is big, use bigger terminal. It doesn't melt. But after some longtime, the plastic start to degrade. The bad about it is that the thick gauge wire will easy broken if the screw too tight. Caps is easy to use. No tool use. Just hand. You need to twist the wire together first. Than twist the cap into the wire till it lock. Don't worry about it. It pretty secure. Unless you not lock it tight enough. It come in many size. So use correctly. There is another type of cap. Which also twist the wire and cap in. Instead of twist the cap, this cap need tool to clamp it. Pretty common in local here. |

|

|

Sep 8 2014, 09:08 PM Sep 8 2014, 09:08 PM

|

All Stars

11,308 posts Joined: Feb 2008 |

QUOTE(weikee @ Sep 8 2014, 09:06 PM) Hard to reach area caps are good. If high current use caps need to be careful may burn if not properly screw, loose connection will cause heat=burn=fire. nowadays the terminal blocks also low quality. sometimes the screw got no thread wan, or bad thread so they come loose and arc. got no branded terminal blocks? |

|

|

Sep 8 2014, 09:13 PM Sep 8 2014, 09:13 PM

|

All Stars

11,308 posts Joined: Feb 2008 |

QUOTE(ozak @ Sep 8 2014, 09:07 PM) Molex connector are more secure and can run higher amp. Can plug/unplug without switch off. No wrong connection pluging since it have a 1way connect. But yes, it need tool to clamp. if one wire is thick (those stiff type - not many strands) and one wire is tiny (very thin), I think the cap may not hold them and the thin wire may come loose. if both wires same size I think i have more confidence they be ok in the long run. Terminal block have been using for very longtime. If the wire size is big, use bigger terminal. It doesn't melt. But after some longtime, the plastic start to degrade. The bad about it is that the thick gauge wire will easy broken if the screw too tight. Caps is easy to use. No tool use. Just hand. You need to twist the wire together first. Than twist the cap into the wire till it lock. Don't worry about it. It pretty secure. Unless you not lock it tight enough. It come in many size. So use correctly. There is another type of cap. Which also twist the wire and cap in. Instead of twist the cap, this cap need tool to clamp it. Pretty common in local here. Im gonna get a bunch of different size to try but have to waste the whole bag if its wrong This post has been edited by idoblu: Sep 8 2014, 09:14 PM |

|

|

Sep 8 2014, 09:17 PM Sep 8 2014, 09:17 PM

|

All Stars

17,021 posts Joined: Jan 2005 |

QUOTE(idoblu @ Sep 8 2014, 09:08 PM) nowadays the terminal blocks also low quality. sometimes the screw got no thread wan, or bad thread so they come loose and arc. got no branded terminal blocks? Oh forget. Terminal block is prefer mostly here is because it easy to make connection to your light. The developer just standby the wire with terminal block at the box. If using cap, developer cannot put a cap on the wire. The wire will be bare like that. It is dangerous. |

|

|

Sep 8 2014, 09:20 PM Sep 8 2014, 09:20 PM

|

Senior Member

519 posts Joined: Jun 2011 |

QUOTE(ozak @ Sep 8 2014, 08:20 PM) Q1 = that is live wire. Not loop. And probably a 3phase wire. Which each color represent R, S, T. Thanks a bundleQ2 = correct. Q3 = if the wire have same color, that mean no polarity. Which way also can. Q4 = if your downlight casing is metal, you need to ground it. In case the light short and somebody touch it. Q5 = correct. If you pull out, others light will not light. Q4 - casing is aluminium I think. All ceiling light, minimum 8 feet high. How to ground it?

That more or less how they look like. |

|

|

Sep 8 2014, 09:23 PM Sep 8 2014, 09:23 PM

|

Senior Member

519 posts Joined: Jun 2011 |

All my life only see terminal blocks everywhere.

The only caps I ever saw is in the Fanco baby fan in my kitchen, made in Singapore. The wireman who installed the fan didn't know how to use it. In the end change to blocks. |

|

|

Sep 8 2014, 09:24 PM Sep 8 2014, 09:24 PM

|

All Stars

17,021 posts Joined: Jan 2005 |

QUOTE(idoblu @ Sep 8 2014, 09:13 PM) if one wire is thick (those stiff type - not many strands) and one wire is tiny (very thin), I think the cap may not hold them and the thin wire may come loose. if both wires same size I think i have more confidence they be ok in the long run. Easy. Teach you some trick.Im gonna get a bunch of different size to try but have to waste the whole bag if its wrong Strip the insulator of both wire longer. Twist together. Than bend the wire u shape. Put the cap in. When you bend the wire u shape, it lock both wire. So you can't pull the small wire out. |

|

|

Sep 8 2014, 09:28 PM Sep 8 2014, 09:28 PM

|

All Stars

17,021 posts Joined: Jan 2005 |

|

|

|

Sep 8 2014, 09:29 PM Sep 8 2014, 09:29 PM

|

All Stars

11,308 posts Joined: Feb 2008 |

QUOTE(ozak @ Sep 8 2014, 09:24 PM) Easy. Teach you some trick. ok will try that. ya man if i use terminal blocks, i also scared the thin wire will break if screwed on too tight...sighStrip the insulator of both wire longer. Twist together. Than bend the wire u shape. Put the cap in. When you bend the wire u shape, it lock both wire. So you can't pull the small wire out. btw developers where got put terminal blocks for you? they leave it bare. they cut the insulation a bit and twist together. |

|

|

Sep 8 2014, 09:33 PM Sep 8 2014, 09:33 PM

|

All Stars

17,021 posts Joined: Jan 2005 |

QUOTE(idoblu @ Sep 8 2014, 09:29 PM) ok will try that. ya man if i use terminal blocks, i also scared the thin wire will break if screwed on too tight...sigh Walau er. Cost down till like that. Not expensive ma the terminal block. btw developers where got put terminal blocks for you? they leave it bare. they cut the insulation a bit and twist together. Last time I still can see terminated with a terminal block on it. |

|

|

Sep 8 2014, 09:34 PM Sep 8 2014, 09:34 PM

|

All Stars

11,308 posts Joined: Feb 2008 |

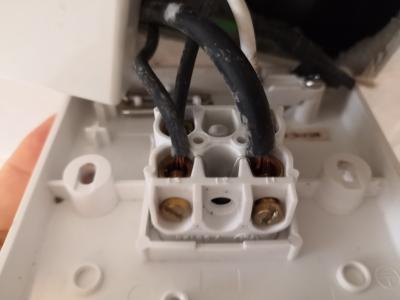

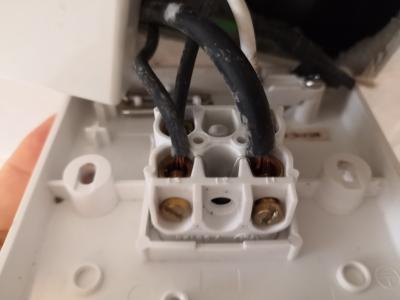

you see how thin these wires.... |

|

|

Sep 8 2014, 09:49 PM Sep 8 2014, 09:49 PM

|

All Stars

17,021 posts Joined: Jan 2005 |

|

|

|

Sep 8 2014, 11:11 PM Sep 8 2014, 11:11 PM

|

All Stars

12,019 posts Joined: Jan 2003 |

QUOTE(idoblu @ Sep 8 2014, 09:29 PM) ok will try that. ya man if i use terminal blocks, i also scared the thin wire will break if screwed on too tight...sigh If Wires too thin, the block will not secure the wires properly. Fold back the wires into the wire insulator, so the top is copper, bottom is wire insulator, put it on the terminal block. This way you secure the wires, and copper are properly touching the conductor.btw developers where got put terminal blocks for you? they leave it bare. they cut the insulation a bit and twist together. |

|

|

Sep 8 2014, 11:14 PM Sep 8 2014, 11:14 PM

|

All Stars

11,308 posts Joined: Feb 2008 |

QUOTE(weikee @ Sep 8 2014, 11:11 PM) If Wires too thin, the block will not secure the wires properly. Fold back the wires into the wire insulator, so the top is copper, bottom is wire insulator, put it on the terminal block. This way you secure the wires, and copper are properly touching the conductor. I wonder if I should not strip the insulation at all. Just tighten the screw till it cuts into the insulation. I always do that for three pin plugs |

|

|

Sep 8 2014, 11:49 PM Sep 8 2014, 11:49 PM

|

All Stars

12,019 posts Joined: Jan 2003 |

|

|

|

Sep 8 2014, 11:56 PM Sep 8 2014, 11:56 PM

|

All Stars

17,021 posts Joined: Jan 2005 |

QUOTE(weikee @ Sep 8 2014, 11:11 PM) If Wires too thin, the block will not secure the wires properly. Fold back the wires into the wire insulator, so the top is copper, bottom is wire insulator, put it on the terminal block. This way you secure the wires, and copper are properly touching the conductor. This way the wire always break inside the insulator after tight the screw. And there is possible the thin wire didn't touch the screw at all. Just the insulator is tight by the screw. There is another way is to get a straight metal connector. Clamp the wire on it. Than screw it to terminal block. |

|

|

Sep 9 2014, 01:20 AM Sep 9 2014, 01:20 AM

|

All Stars

12,019 posts Joined: Jan 2003 |

QUOTE(ozak @ Sep 8 2014, 11:56 PM) This way the wire always break inside the insulator after tight the screw. And there is possible the thin wire didn't touch the screw at all. Just the insulator is tight by the screw. Roll the wires together, and turn it back to touch the insulator. This will work better. if have soldering, just solder the copper and put inside the block. There is another way is to get a straight metal connector. Clamp the wire on it. Than screw it to terminal block. BTW, lots of people don't know how to join wires when solder. This site show proper way http://www.ripsdiy.co.za/cablesandwires.shtml |

|

|

Sep 9 2014, 01:22 AM Sep 9 2014, 01:22 AM

|

All Stars

12,019 posts Joined: Jan 2003 |

|

|

|

Sep 9 2014, 04:37 PM Sep 9 2014, 04:37 PM

|

Junior Member

96 posts Joined: Dec 2012 |

QUOTE(Fazab @ Sep 8 2014, 06:03 PM) Reviving an old thread to get advice from sifus....... gentle reminder, in case ur unaware. if you have plaster ceiling, you cant drill and mount the light directly. the plaster ceiling does not offer you any 'grip', you'll simply puncture the ceiling with your screw.I jut bought bout 3 dozen lights for new house, mostly ceiling mounted led panels. The shop's installer say standard rate is RM15 to install one light. I reckon each job will require : 2 screws to fit light to ceiling, connect 2 wires, pop the cover back. Most of the ceiling is plaster ceiling board. Drilling not a problem. So I am thinking to DIY myself. Before I fried myself or burn a row of houses, can sifus check if I got the theory part right : Most of my lighting points like this :    Q1 The middle wire can be red, yellow or blue. I think this is the wireman's way to identify each 'loop' Correct? Q2 So the Black = Neutral; Red/Yellow/Blue = Live; Green is Earth. Correct?  Q3 The LED lights has 2 tiny blue wires. These are to be connected to the Neutral (Black) and Live (R/Y/B) Which way also OK. Correct? Q4 No need to use Earth (Green) wire. Correct ah? Q5 There are two black and green wires each because of looping. Just leave them alone. Don't pull out. Correct? what you need to do is place a piece of wood, about 20% bigger than your light, secure the wood to plaster ceiling, then you can mount your ceiling light by drilling thru the plaster ceiling and using the wood as grip. |

|

|

Sep 9 2014, 07:53 PM Sep 9 2014, 07:53 PM

|

Senior Member

519 posts Joined: Jun 2011 |

I was going to ask this question.

plaster ceiling guy say can drill, but must find when is the supporting steel bars, and fix the screw thru that. but he didn't tell me how to find the steel bar from below. I need X-ray eyes.......? Magnet? |

|

|

Sep 9 2014, 08:43 PM Sep 9 2014, 08:43 PM

|

All Stars

11,308 posts Joined: Feb 2008 |

depends on what kind of lights. if concealed downlights, they just pop into the hole and the spring clip prevents it from falling down. no screws required. the plaster ceiling support beams are aluminum so magnet wont help. you can cut open a hole to see where they are i suppose and patch the hole back. maybe stud detector can work?

|

|

|

Sep 9 2014, 11:46 PM Sep 9 2014, 11:46 PM

|

All Stars

17,021 posts Joined: Jan 2005 |

QUOTE(Fazab @ Sep 9 2014, 07:53 PM) I was going to ask this question. Easy la. Just get some plaster ceiling screw plug. Come in few shape and style. Google it.plaster ceiling guy say can drill, but must find when is the supporting steel bars, and fix the screw thru that. but he didn't tell me how to find the steel bar from below. I need X-ray eyes.......? Magnet? |

|

|

Sep 12 2014, 09:00 AM Sep 12 2014, 09:00 AM

|

Senior Member

519 posts Joined: Jun 2011 |

My Indon handyman laugh when I asked him. He said the unit is so light, just use normal screws can. If lazy use double sided tape also can.

I ask him how much he charge to fit a light........he also want RM15. Indon also expensive oledi. |

|

|

Oct 29 2014, 09:15 AM Oct 29 2014, 09:15 AM

|

Senior Member

519 posts Joined: Jun 2011 |

Done fixing lights. Just sharing silly experiences and thanking the sifus here for their advises, and double check anything I missed.

1. Fix light to plaster ceiling without light dropping True that plaster ceiling board do not provide enough grip. Before I started, I got a 'competent' installer to fit two lights and I watched him all the way. He just drill and used normal wall plugs. If I pull hard on the light, it moves..... OK don't pull it then. I did the rest using a safer but more tiring way First I try to get to an aluminium bar above the plaster board. Turns out that in most cases the plaster ceiling man will have fixed a bar near the lighting point. If I find it I put at least one screw into the aluminium bar. That gives good hold. How to find it? First I put middle finger in the wiring hole and feel feel around (OK, don't get naughty thoughts) If finger not long enough I use a small drill bit and poke around from outside (also no naughty thoughts) to find it. Then I just patch up the small holes. If no aluminium bar nearby, I use 'butterfly' wall plugs. This one a bit problem because they are thick and big, have to make a big hole to push it through. Also, the thinnest plug I can find is 10mm thick at the base. If the plaster board is less than 9mm thick, it does not sit flush to the ceiling, but won't come out. So OK. Safe. But once you put the plug in you can't pull it out. To remove, only way is to push the whole thing in, and patch the big hole. 2. The earth wire. For small LED lights, casing is plastic, so I no fix the earth wire, just left them in the connector. For the big ones with aluminium casings, I copycat the installer - remove the green wires from the connector, strip about one inch of tubing from each, twist them together, and join to one of the supporting screws. 3. Wiring the LED lights This is the part I had the most problem, because the LED wires are b***** tiny. Quite difficult to get the screw of the connectors to sit on the wires. End up I bend the tip into a hook, push it in as far as possible, and screw down onto the tubing hard. So the LED wires will directly contact the house wires on the other side. 4. End results - so far so good All lights work. One a bit senget (tip : buy round shape ones, no matter how you mess up, they can't go senget) Lights secured by butterfly plugs may have a tiny but noticable gap between the base and ceiling if your board is thin. (tip : find better plugs) 5. Conclusion - maybe I should have just get people to do it........got neckache now. (Tip : make sure ladder is tall enough, and you don't have weak knees problem) |

|

|

Apr 30 2015, 04:33 PM Apr 30 2015, 04:33 PM

|

Senior Member

519 posts Joined: Jun 2011 |

OK, I got into another silly situation.

Wanted to fit timer and sensor switches to front and back lights before balik kampung long weekend. But the only wireman who will do this 'small job' failed to turn up - twice. So for last minute desperate measure, I plan to buy socket timers, plugs, and long wires. I will fit the wire --> plug --> then plug into timer --> wall socket Then I will temporarily swap the wires from the lights to the new wires (connect using terminal blocks) Now the lights will be connected thru socket timers I think this will work. Is there ANYTHING that I need to be careful of? Overlooked? Sorry, I DIY a lot, but a bit panciky when come to electric. The wires will be 10 - 20 feet long. Bankrupt..... |

|

|

Apr 30 2015, 04:56 PM Apr 30 2015, 04:56 PM

|

Junior Member

254 posts Joined: Feb 2006 |

Hi !

Need expert advise, I have few unused wall lighting extension. I was wondering can I use it as the power for radio or for charging phone / notebook? I was thinking of buying extension power cord and connect to the wire extension. Can it take the load? Please advise! Thanks in advance. |

|

|

Apr 30 2015, 06:15 PM Apr 30 2015, 06:15 PM

|

All Stars

17,021 posts Joined: Jan 2005 |

QUOTE(Fazab @ Apr 30 2015, 04:33 PM) OK, I got into another silly situation. Just don't get yourself injure. Makesure you tape the incoming wire properly that temporary not use.Wanted to fit timer and sensor switches to front and back lights before balik kampung long weekend. But the only wireman who will do this 'small job' failed to turn up - twice. So for last minute desperate measure, I plan to buy socket timers, plugs, and long wires. I will fit the wire --> plug --> then plug into timer --> wall socket Then I will temporarily swap the wires from the lights to the new wires (connect using terminal blocks) Now the lights will be connected thru socket timers I think this will work. Is there ANYTHING that I need to be careful of? Overlooked? Sorry, I DIY a lot, but a bit panciky when come to electric. The wires will be 10 - 20 feet long. Bankrupt..... |

|

|

Apr 30 2015, 06:16 PM Apr 30 2015, 06:16 PM

|

All Stars

17,021 posts Joined: Jan 2005 |

QUOTE(aranel @ Apr 30 2015, 04:56 PM) Hi ! What is lighting extension ?Need expert advise, I have few unused wall lighting extension. I was wondering can I use it as the power for radio or for charging phone / notebook? I was thinking of buying extension power cord and connect to the wire extension. Can it take the load? Please advise! Thanks in advance. |

|

|

Apr 30 2015, 11:59 PM Apr 30 2015, 11:59 PM

Show posts by this member only | IPv6 | Post

#52

|

Junior Member

254 posts Joined: Feb 2006 |

|

|

|

May 25 2015, 10:34 PM May 25 2015, 10:34 PM

|

Senior Member

565 posts Joined: Jan 2003 From: KL,IPOH. |

hi guys, I have a question,

For kitchen hood, if power supply is control via switch, do i need to use 20A switch or normal switch for lights is good enough? |

|

|

May 26 2015, 07:44 AM May 26 2015, 07:44 AM

|

Senior Member

1,167 posts Joined: May 2009 |

|

|

|

May 26 2015, 08:06 AM May 26 2015, 08:06 AM

|

Senior Member

11,554 posts Joined: Aug 2009 |

QUOTE(yanjinowa @ May 25 2015, 10:34 PM) hi guys, I have a question, As long as the appliance that involving a motor, compressor, heater you shall install a dedicated 20A switch.For kitchen hood, if power supply is control via switch, do i need to use 20A switch or normal switch for lights is good enough? |

|

|

May 26 2015, 09:59 AM May 26 2015, 09:59 AM

|

Senior Member

565 posts Joined: Jan 2003 From: KL,IPOH. |

QUOTE(JunJun04035 @ May 26 2015, 07:44 AM) QUOTE(supersound @ May 26 2015, 08:06 AM) As long as the appliance that involving a motor, compressor, heater you shall install a dedicated 20A switch. Hi, the rating motor power is 200W, and input power is 208W. So, it is advisable to have a 20A switch, then i will have to buy one... i bought the normal switch. Btw, whats the amount of A can be handle with normal switch? i have the Schneider KB31-1. Thank you. |

|

|

May 26 2015, 11:01 AM May 26 2015, 11:01 AM

|

Senior Member

1,167 posts Joined: May 2009 |

|

|

|

May 26 2015, 11:03 AM May 26 2015, 11:03 AM

|

Senior Member

1,167 posts Joined: May 2009 |

QUOTE(yanjinowa @ May 26 2015, 09:59 AM) Hi, the rating motor power is 200W, and input power is 208W. 20A switch for 200W is definitely overkill. Even a 13A plug is sufficient lor So, it is advisable to have a 20A switch, then i will have to buy one... i bought the normal switch. Btw, whats the amount of A can be handle with normal switch? i have the Schneider KB31-1. Thank you. |

|

|

May 26 2015, 11:18 AM May 26 2015, 11:18 AM

|

Senior Member

565 posts Joined: Jan 2003 From: KL,IPOH. |

|

|

|

May 26 2015, 12:14 PM May 26 2015, 12:14 PM

|

Senior Member

11,554 posts Joined: Aug 2009 |

QUOTE(yanjinowa @ May 26 2015, 09:59 AM) Hi, the rating motor power is 200W, and input power is 208W. By theory, yes, a normal switch will do, but for safety(since most of us will install and use until it fails), 20A will be better, in case you are going to change it to higher rating type later on.So, it is advisable to have a 20A switch, then i will have to buy one... i bought the normal switch. Btw, whats the amount of A can be handle with normal switch? i have the Schneider KB31-1. Thank you. QUOTE(JunJun04035 @ May 26 2015, 11:01 AM) That's why I said any appliance |

|

|

Jul 19 2015, 01:50 PM Jul 19 2015, 01:50 PM

|

Junior Member

32 posts Joined: Jan 2007 |

Hi!

Need some advice I have 2 20A switches in my kitchen which are unused:  When I first renovated years ago, I couldn't decide if I wanted to get a microwave and oven fitted into my kitchen cabinet, so I left those cabinet empty, and my contractor just terminated the wires for me. Top:  Bottom:  Questions that I have: 1. What is the difference between the top configurations and the bottom configurations? 2. I want to buy a microwave with oven combo: Something like this specs: Panasonic Microwave Oven These microwave ovens normally come with a normal 3-pin plug. Can I remove the plug and connect the microwave wires directly to the 20A switch wires via the terminal connectors? Thank you in advance for replying! |

|

|

Jul 19 2015, 03:24 PM Jul 19 2015, 03:24 PM

|

All Stars

12,019 posts Joined: Jan 2003 |

QUOTE(klaw @ Jul 19 2015, 01:50 PM) Hi! both the same, the one you see 2 green because the earth is loop to another location and you must have both the earth connected.Need some advice I have 2 20A switches in my kitchen which are unused:  When I first renovated years ago, I couldn't decide if I wanted to get a microwave and oven fitted into my kitchen cabinet, so I left those cabinet empty, and my contractor just terminated the wires for me. Top:  Bottom:  Questions that I have: 1. What is the difference between the top configurations and the bottom configurations? 2. I want to buy a microwave with oven combo: Something like this specs: Panasonic Microwave Oven These microwave ovens normally come with a normal 3-pin plug. Can I remove the plug and connect the microwave wires directly to the 20A switch wires via the terminal connectors? Thank you in advance for replying! Not advisable, get a box, put in a socket, and use that sockect for your microware oven, the plug supply by microwave is for safety measurement, it have a 13amps fused. |

|

|

Jul 19 2015, 06:14 PM Jul 19 2015, 06:14 PM

|

All Stars

11,308 posts Joined: Feb 2008 |

.

This post has been edited by idoblu: Apr 26 2016, 07:58 PM |

|

|

Dec 3 2015, 02:14 PM Dec 3 2015, 02:14 PM

|

Junior Member

79 posts Joined: Apr 2012 |

QUOTE(weikee @ Jul 19 2015, 03:24 PM) both the same, the one you see 2 green because the earth is loop to another location and you must have both the earth connected. hey guys if i want to conceal a wiring casing inside my wall so that i can use it to hide my power cords between my plug point and my appliances. any casing to recommend?Not advisable, get a box, put in a socket, and use that sockect for your microware oven, the plug supply by microwave is for safety measurement, it have a 13amps fused. |

|

|

Dec 12 2015, 01:38 PM Dec 12 2015, 01:38 PM

|

Junior Member

145 posts Joined: Oct 2005 |

Hi guys, need some advice here.

I just bought a new switch for my water heater. There are 2L2N and 1 symbol like wifi which I think it should be G (5 holes in total). When I open the old switch, I realise that there are 2 black, 1 blue, 1 red and 2 green wires. Should I just connect the 2 green wires to G? |

|

|

Apr 26 2016, 06:01 PM Apr 26 2016, 06:01 PM

|

Junior Member

102 posts Joined: May 2008 |

QUOTE(scorpiok @ Dec 12 2015, 01:38 PM) Hi guys, need some advice here. If by "Wifi symbol" you mean this:I just bought a new switch for my water heater. There are 2L2N and 1 symbol like wifi which I think it should be G (5 holes in total). When I open the old switch, I realise that there are 2 black, 1 blue, 1 red and 2 green wires. Should I just connect the 2 green wires to G? | ----- --- - Thats not "wifi" symbol thats the symbol for Earth-Ground Sounds like you have a DPST switch which is common for high current things like water heater. 1N and 1L should be on one side, and on the other side is another N and L correct? The Green wires are earth and looped (which is correct) so yes you connect it to the Ground point in the switch. Blue and Red are the live wires. Im guessing the Blue wire is the thicker one built into the wall? Connect that to the "point 1" of the switch, then connect red to the "point 2" of the switch. - MAKE SURE YOU TURN OFF MAIN POWER FIRST! Then connect the black wires to the Neutral, following the same order so that the supply line and line to the water heater are not crossed. If in doubt consult an electrician. |

|

|

Oct 4 2017, 06:30 PM Oct 4 2017, 06:30 PM

|

Newbie

6 posts Joined: Oct 2017 |

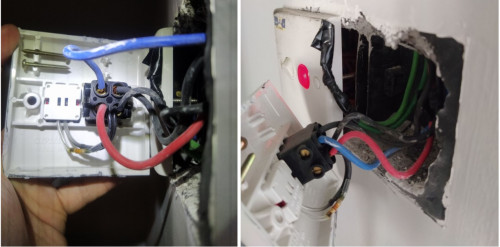

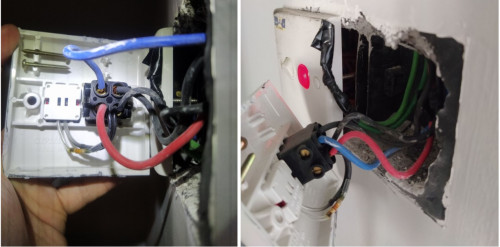

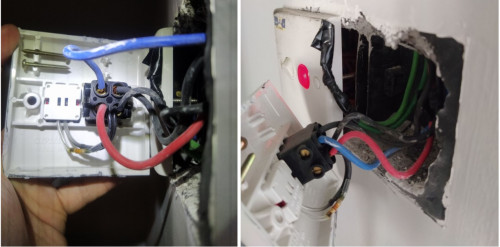

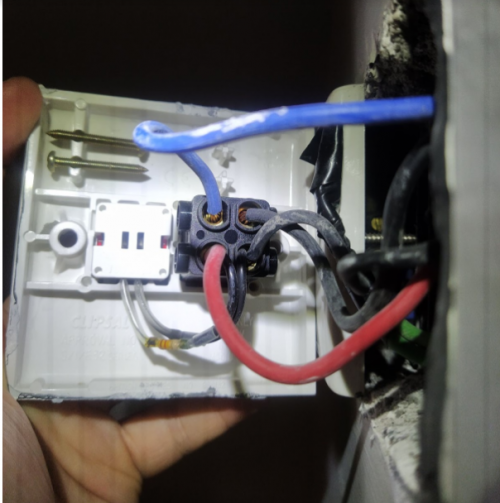

I am trying to buy Aqara smart wall switch to replace existing wall switch. I need to decide whether I can buy the version with neutral line.

When I opened the existing switch, I found this as attached. Does it mean that there is no neutral line? Or it is just that the electrician uses red wire as neutral? Thank you. This post has been edited by taipan70: Oct 6 2017, 09:48 AM Attached thumbnail(s)

|

|

|

Jan 2 2018, 11:46 AM Jan 2 2018, 11:46 AM

|

Senior Member

2,948 posts Joined: Jun 2007 |

QUOTE(ozak @ Sep 8 2014, 09:28 PM) hi, do downlight need to connect Earth as usually they only have Live & Neutral and unlike surface mounted they have plastic casing.so for surface mounted can i just use an earth crimp connector (looks like a washer) and put it in between the light support mount & the screw onto the ceiling? what about normal pendant lights? same thing connect earth to metal part of the body? and do contractors normally pull Earth wire when doing looping for downlights or just pull Live & Neutral? |

|

|

Jan 2 2018, 12:43 PM Jan 2 2018, 12:43 PM

|

All Stars

17,021 posts Joined: Jan 2005 |

QUOTE(advocado @ Jan 2 2018, 11:46 AM) hi, do downlight need to connect Earth as usually they only have Live & Neutral and unlike surface mounted they have plastic casing. Any metal frame need to be ground it.so for surface mounted can i just use an earth crimp connector (looks like a washer) and put it in between the light support mount & the screw onto the ceiling? what about normal pendant lights? same thing connect earth to metal part of the body? and do contractors normally pull Earth wire when doing looping for downlights or just pull Live & Neutral? You need to advise the contractor to pull the earth wire together if they don't. |

|

|

Jan 2 2018, 01:51 PM Jan 2 2018, 01:51 PM

|

Senior Member

2,948 posts Joined: Jun 2007 |

QUOTE(ozak @ Jan 2 2018, 12:43 PM) Any metal frame need to be ground it. ok, so for downlight no need because their casing are made of plastic, just need to remember to turn off switch & DB when changing it as the clips are still metal?You need to advise the contractor to pull the earth wire together if they don't. |

|

|

Jan 2 2018, 02:00 PM Jan 2 2018, 02:00 PM

|

All Stars

17,021 posts Joined: Jan 2005 |

|

|

|

Jan 2 2018, 02:07 PM Jan 2 2018, 02:07 PM

|

Senior Member

2,948 posts Joined: Jun 2007 |

|

|

|

Jan 2 2018, 02:20 PM Jan 2 2018, 02:20 PM

|

All Stars

17,021 posts Joined: Jan 2005 |

|

|

|

Jan 4 2018, 11:55 PM Jan 4 2018, 11:55 PM

|

Junior Member

35 posts Joined: Sep 2005 |

QUOTE(taipan70 @ Oct 4 2017, 06:30 PM) I am trying to buy Aqara smart wall switch to replace existing wall switch. I need to decide whether I can buy the version with neutral line. Actually I am also facing the same issue.When I opened the existing switch, I found this as attached. Does it mean that there is no neutral line? Or it is just that the electrician uses red wire as neutral? Thank you. Anyone can confirm what is the correct line configuration in the picture? Live + Neutral? ??? |

|

|

Jan 5 2018, 08:38 AM Jan 5 2018, 08:38 AM

|

All Stars

17,021 posts Joined: Jan 2005 |

QUOTE(CooKies37 @ Jan 4 2018, 11:55 PM) Actually I am also facing the same issue. https://forum.lowyat.net/topic/3554748/+1640Anyone can confirm what is the correct line configuration in the picture? Live + Neutral? ??? |

|

|

Jan 5 2018, 09:51 AM Jan 5 2018, 09:51 AM

|

Junior Member

35 posts Joined: Sep 2005 |

QUOTE(ozak @ Jan 5 2018, 08:38 AM) I don't understand? That thread just discuss about some switch from china require N line or no.I am asking about the photo posted, is it all Live only? or there is N line? or ??? |

|

|

Jan 5 2018, 09:56 AM Jan 5 2018, 09:56 AM

|

All Stars

17,021 posts Joined: Jan 2005 |

|

|

|

Jan 5 2018, 10:34 AM Jan 5 2018, 10:34 AM

|

Senior Member

2,948 posts Joined: Jun 2007 |

|

|

|

Jan 20 2018, 08:31 AM Jan 20 2018, 08:31 AM

|

Senior Member

2,948 posts Joined: Jun 2007 |

QUOTE(ozak @ Apr 30 2015, 06:15 PM) Just don't get yourself injure. Makesure you tape the incoming wire properly that temporary not use. hi, is it true if you buy those programmable switch like Honeywell, to use it as light switch we need to pull the neutral line from the light wires to the switch? the light switch itself won't have the Neutral wire? it's a schneider light switch i plan to replace. |

|

|

Jan 20 2018, 08:34 AM Jan 20 2018, 08:34 AM

|

Senior Member

2,948 posts Joined: Jun 2007 |

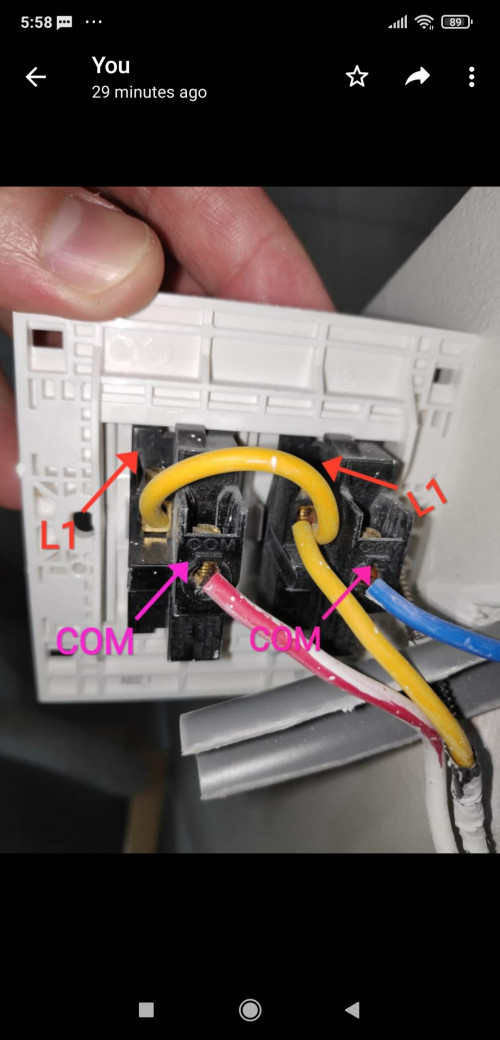

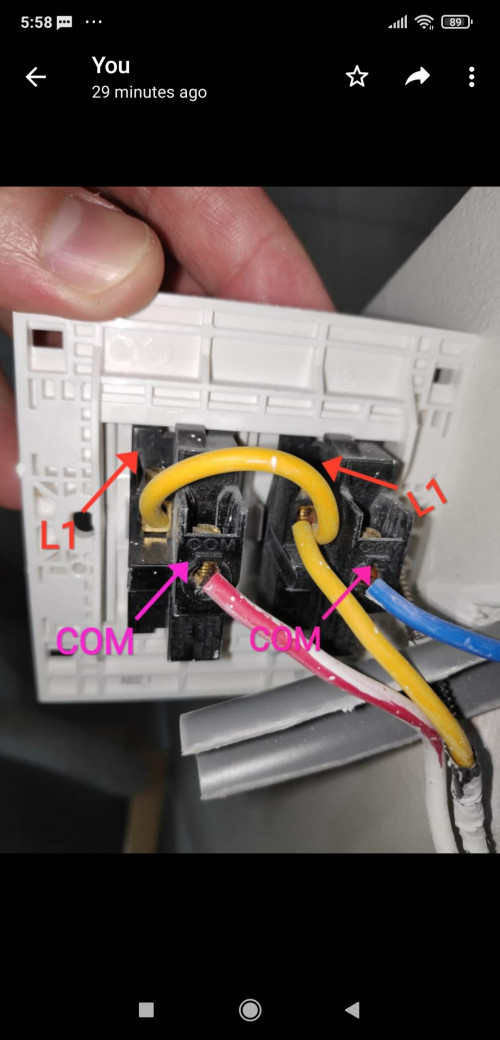

QUOTE(ozak @ Jan 5 2018, 09:56 AM) hi, i looked at your picture again, i figure the rows of wire on top are Switch Live, the MCB Live comes at the bottom and is looped to the other 2 switches, but i'm seeing both left & right side got MCB Live coming in, so my question is why is there 2 Live + 2 Loop wires in the switch? |

|

|

Apr 4 2018, 02:13 AM Apr 4 2018, 02:13 AM

|

Senior Member

1,139 posts Joined: Aug 2006 |

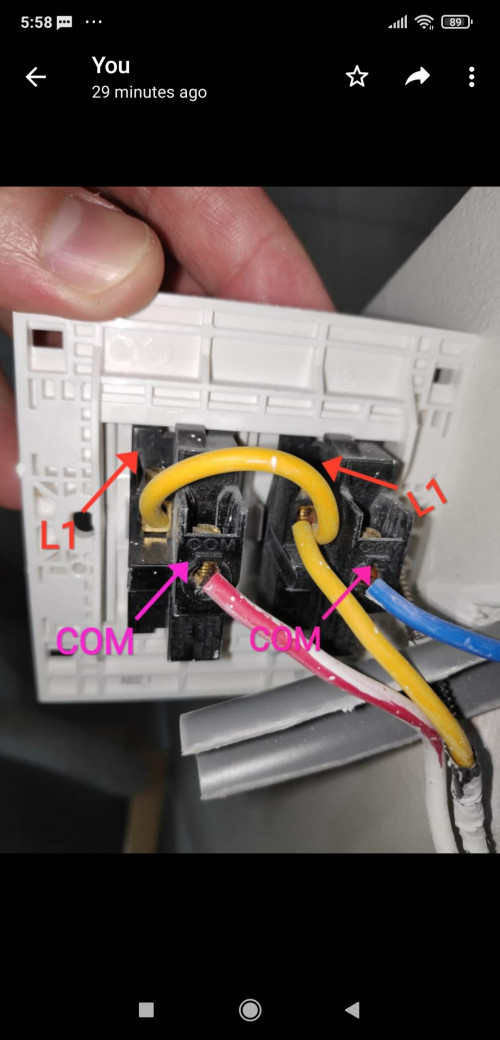

Dear Sifu..

Need some advise and help here. Objective: To provide Neutral Wire to my light switch for my new smart switch Situation: I have 2 Gang Light Switch (for fan and lamp) next to Aircond switch Q 1: Can I jumper the neutral in of aircond switch cable to provide Neutral in to the new switch? I'm not sure if the Air Cond and light from same circuit, which I don't think so. Q 2: Is it okey to tap neutral from the ceiling light itself? or should i tap from the ceiling fan? Q 3: What is the black and green wire inside the double gang light switch? I have multimeter and perhaps I will test out to be sure, but early advise will be great Last option is to tap new wire from the circuit box, but i will have additional 8 lighting switch point to replace For reference and better understanding, please refer to both image i provide in this post

Thank you!!!! |

|

|

Apr 4 2018, 08:36 AM Apr 4 2018, 08:36 AM

Show posts by this member only | IPv6 | Post

#82

|

Senior Member

6,914 posts Joined: Apr 2007 |

q1 : how many rcd or elcb the electrical board has? if 1 then yes, you can loop the neutral from aircon switch. q2 : not necessary. q3 : green should be earth that is wrapped with some wire tape to direct connect them together. black one should be neutral that is direct connect with wire tape. be careful ok. and never assume wire function and phase based on wire color alone. always test before touching. be careful about neutral that is direct connect. sometimes when you separate them, a neutral that is disconnected from the neutral link becomes a live wire. so, you should know what you are doing before proceeding. good luck. aronteh liked this post

|

|

|

Apr 4 2018, 05:14 PM Apr 4 2018, 05:14 PM

|

Senior Member

1,139 posts Joined: Aug 2006 |

QUOTE(slimey @ Apr 4 2018, 08:36 AM) q1 : how many rcd or elcb the electrical board has? if 1 then yes, you can loop the neutral from aircon switch. Thanks for your reply.q2 : not necessary. q3 : green should be earth that is wrapped with some wire tape to direct connect them together. black one should be neutral that is direct connect with wire tape. be careful ok. and never assume wire function and phase based on wire color alone. always test before touching. be careful about neutral that is direct connect. sometimes when you separate them, a neutral that is disconnected from the neutral link becomes a live wire. so, you should know what you are doing before proceeding. good luck. Yes I will test with Non Contact Volt Meter and also close the circuit before performing the job. I will test and update later.. Thank you |

|

|

Apr 5 2018, 10:00 PM Apr 5 2018, 10:00 PM

|

Senior Member

1,139 posts Joined: Aug 2006 |

QUOTE(slimey @ Apr 4 2018, 08:36 AM) q1 : how many rcd or elcb the electrical board has? if 1 then yes, you can loop the neutral from aircon switch. Manage to install the neutral cable without any issue.q2 : not necessary. q3 : green should be earth that is wrapped with some wire tape to direct connect them together. black one should be neutral that is direct connect with wire tape. be careful ok. and never assume wire function and phase based on wire color alone. always test before touching. be careful about neutral that is direct connect. sometimes when you separate them, a neutral that is disconnected from the neutral link becomes a live wire. so, you should know what you are doing before proceeding. good luck. 1. test with multimeter 2. Extend the cable with connector / coupler and cover it with electrical tape for added security 3. Install and all working fine. Thanks alot |

|

|

Aug 27 2018, 02:14 AM Aug 27 2018, 02:14 AM

|

Senior Member

785 posts Joined: Jan 2003 |

I use many types of crimper & tools.

1. Ferrule - insulated & bare (mainly DB, etc) 2. Splice/Lock crimp - good for LED downlight 3. Wire nut/Screw on - cheap & fast 4. Spring/Push Type & Clamp Quick (for thin wire, testing project) 5. Terminal block (Malaysia 1970s technology) 1-4 : Buy from Shopee / Taobao 5 : Buy from local hardware This post has been edited by amco: Aug 27 2018, 02:14 AM |

|

|

Oct 17 2018, 11:42 AM Oct 17 2018, 11:42 AM

|

Junior Member

86 posts Joined: Jan 2003 From: Komino |

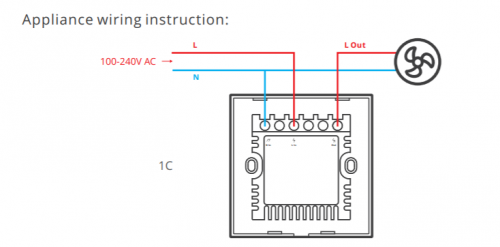

|

|

|

Oct 17 2018, 11:47 AM Oct 17 2018, 11:47 AM

|

Junior Member

498 posts Joined: Jul 2006 |

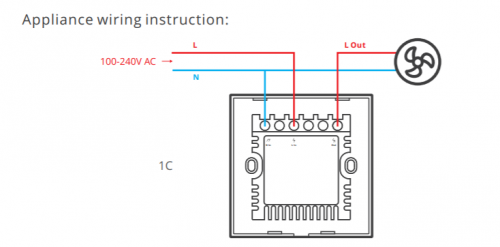

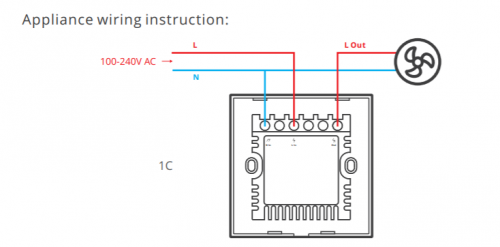

L = live L vs L1 is just to differentiate input/ouput (usually) e.g the incoming live is into the L and the outgoing live to the load into the L1 but its kinda weird for not having N1 as well. check some quick guide/manual that supposed to be attached with that switch. should have some info on wiring diagram skyklg liked this post

|

|

|

Oct 17 2018, 11:54 AM Oct 17 2018, 11:54 AM

|

Junior Member

498 posts Joined: Jul 2006 |

after my post above i go google for a quick check. yes its correct.

the N is just one. u have to loop it but you trouble would be that: 1. common wiring practice don't have N into the switch box 2. have to source for N which will be impossible if there's no conduit in the wall (mostlikely contractor just plaster the wire in) looking at your switch i guess how it work is: the switch needs power to operate thus it requires N basically the N and L together is to power up your switch then the L1 is to forward the Live for a complete circuit |

|

|

Oct 17 2018, 01:55 PM Oct 17 2018, 01:55 PM

|

Junior Member

86 posts Joined: Jan 2003 From: Komino |

QUOTE(ungka @ Oct 17 2018, 11:47 AM) L = live sadly the manual is in Mandarin and I don't real Mandarin L vs L1 is just to differentiate input/ouput (usually) e.g the incoming live is into the L and the outgoing live to the load into the L1 but its kinda weird for not having N1 as well. check some quick guide/manual that supposed to be attached with that switch. should have some info on wiring diagram |

|

|

Oct 17 2018, 05:24 PM Oct 17 2018, 05:24 PM

|

Junior Member

498 posts Joined: Jul 2006 |

QUOTE(RaFe @ Oct 17 2018, 01:55 PM) actually not that hard. but i doubt it'll be doable.workaround is possible but might be ugly or tedious. if want simple it'll be ugly if want nice proper its really tedious. to me it's like need partial rewiring |

|

|

Dec 29 2019, 04:06 PM Dec 29 2019, 04:06 PM

|

Senior Member

943 posts Joined: Jun 2010 |

my mirror light plug gone case already the plug.. and i want to DIY change the plug but after i dismantle the existing plug.. inside only have Black and Red wire..

first time encounter 2 wire.. as normally it 3 wire.. please help sifu.. current existing input = AC 100-240V 50/60Hz output = 12v Existing is using china head plug. |

|

|

Jun 22 2020, 02:27 PM Jun 22 2020, 02:27 PM

Show posts by this member only | IPv6 | Post

#92

|

Junior Member

832 posts Joined: Jul 2016 |

QUOTE(cherroy @ Jun 11 2011, 12:06 AM) Please do not DIY if you even not know how to differentiate green, blue and black in the first place. Hi. Can you advice on this. Hire electrician to do the job, electricity can be dangerous, if not know to handle it. Standard Black - live Blue - neutral Green - earth. Why Live is connected to Neutral and Neutral to Live? Thanks Attached thumbnail(s)

|

|

|

Jun 22 2020, 02:44 PM Jun 22 2020, 02:44 PM

|

All Stars

11,667 posts Joined: Jan 2003 From: Klang/Subang |

QUOTE(JasonTheGreat @ Jun 22 2020, 02:27 PM) Because, humans make mistakes.Just like traffic light, red is stop, green is go, but millions of people still beat red light. Colour code supposed to be standardise but theres a lot of faux electrician out there simply connect using any colour. And it gets more complicated if its looping (ie not direct DB because if you change it at one end it might still be wrong halfway- need to trace back that circuit whether it is just that one circuit or others also affected. If you can confirm using test pen that the live is the hot one, turn off whole DB box, check again and confirm with working test pen that all are off already, then swap the bottom pair (clean wires without paint) correctly, then it should be OK. That's why rule #1 always assume previous faux electrician is an idiota, test to confirm your test pen is working, test test test before touching any wires, NEVER WORK HOT (live). Always assume the wire is hot and make sure to confirm the DB box is all off as well, even after lunch break always assume someone has turned it on, test test test, and colours are installed by colour blind previous faux electrician. This post has been edited by ceo684: Jun 22 2020, 02:51 PM JasonTheGreat liked this post

|

|

|

Jun 22 2020, 02:48 PM Jun 22 2020, 02:48 PM

|

All Stars

11,667 posts Joined: Jan 2003 From: Klang/Subang |

In the wall, stiff wire, usually it is

Live - Red Yellow Blue sometimes white, depending on phase Neutral - Black (common neutral) Earth - Green Outside of wall - to fitting/flexible cable, usually it is Live - Red/Brown Neutral - Blue Earth - Yellow/Green stripes or Green This post has been edited by ceo684: Jun 22 2020, 02:48 PM |

|

|

Jun 22 2020, 03:51 PM Jun 22 2020, 03:51 PM

Show posts by this member only | IPv6 | Post

#95

|

Junior Member

832 posts Joined: Jul 2016 |

QUOTE(ceo684 @ Jun 22 2020, 02:44 PM) Because, humans make mistakes. Thanks. I have confirmed with test pen. The one I circled from incoming (Blue line) is actually LIVE WIRE. Crap man how these licensed electrician does the 3 phase wiring. So dangerous. Just like traffic light, red is stop, green is go, but millions of people still beat red light. Colour code supposed to be standardise but theres a lot of faux electrician out there simply connect using any colour. And it gets more complicated if its looping (ie not direct DB because if you change it at one end it might still be wrong halfway- need to trace back that circuit whether it is just that one circuit or others also affected. If you can confirm using test pen that the live is the hot one, turn off whole DB box, check again and confirm with working test pen that all are off already, then swap the bottom pair (clean wires without paint) correctly, then it should be OK. That's why rule #1 always assume previous faux electrician is an idiota, test to confirm your test pen is working, test test test before touching any wires, NEVER WORK HOT (live). Always assume the wire is hot and make sure to confirm the DB box is all off as well, even after lunch break always assume someone has turned it on, test test test, and colours are installed by colour blind previous faux electrician. Attached thumbnail(s)

|

|

|

Jun 22 2020, 04:44 PM Jun 22 2020, 04:44 PM

|

Senior Member

1,132 posts Joined: Apr 2014 From: Shah Alam, Selangor |

QUOTE(JasonTheGreat @ Jun 22 2020, 03:51 PM) Thanks. I have confirmed with test pen. The one I circled from incoming (Blue line) is actually LIVE WIRE. Crap man how these licensed electrician does the 3 phase wiring. So dangerous. The wiring is correct as done by the electrician in your picture. You are wrong in your assumption that the electrician has done a dangerous job. I'm not trying to be condescending here, but please understand the wiring standards before you do wiring. Please be safe. |

|

|

Jun 22 2020, 07:29 PM Jun 22 2020, 07:29 PM

Show posts by this member only | IPv6 | Post

#97

|

Junior Member

832 posts Joined: Jul 2016 |

QUOTE(stormer.lyn @ Jun 22 2020, 04:44 PM) The wiring is correct as done by the electrician in your picture. You are wrong in your assumption that the electrician has done a dangerous job. I'm not trying to be condescending here, but please understand the wiring standards before you do wiring. Please be safe. Okay. So the color code changed?Attached thumbnail(s)

|

|

|

Jun 22 2020, 07:38 PM Jun 22 2020, 07:38 PM

|

Senior Member

1,132 posts Joined: Apr 2014 From: Shah Alam, Selangor |

The only difference is that the Earth/Ground cable is solid green, not green striped yellow in M'sia. QUOTE(JasonTheGreat @ Jun 22 2020, 07:29 PM) As ceo684 has posted before, the colour code within the wall is different from the colour code for flexible wire.QUOTE(ceo684 @ Jun 22 2020, 02:48 PM) In the wall, stiff wire, usually it is This post has been edited by stormer.lyn: Jun 22 2020, 07:43 PMLive - Red Yellow Blue sometimes white, depending on phase Neutral - Black (common neutral) Earth - Green Outside of wall - to fitting/flexible cable, usually it is Live - Red/Brown Neutral - Blue Earth - Yellow/Green stripes or Green |

|

|

Jun 28 2020, 05:31 PM Jun 28 2020, 05:31 PM

|

Junior Member

36 posts Joined: Feb 2012 |

|

|

|

Jun 28 2020, 07:12 PM Jun 28 2020, 07:12 PM

|

Senior Member

1,132 posts Joined: Apr 2014 From: Shah Alam, Selangor |

|

|

|

Jun 28 2020, 08:23 PM Jun 28 2020, 08:23 PM

|

Junior Member

36 posts Joined: Feb 2012 |

|

|

|

Nov 13 2020, 12:25 AM Nov 13 2020, 12:25 AM

|

Junior Member

10 posts Joined: Jan 2011 |

|

|

|

Nov 13 2020, 07:29 AM Nov 13 2020, 07:29 AM

Show posts by this member only | IPv6 | Post

#103

|

Senior Member

1,132 posts Joined: Apr 2014 From: Shah Alam, Selangor |

|

|

|

Nov 18 2020, 04:39 PM Nov 18 2020, 04:39 PM

|

Senior Member

5,867 posts Joined: Feb 2006 |

Hi, anyone can identify which L and N wires goes to Load? because there is no Load marking on the switch itself. I only see only L1, L2 and L3.

The white colour wire is incoming Live from the DB and I need to find out which is the incoming N and out going L and N that goes to the Load. PDL 20A switch

View from the bottom

View from the top

|

|

|

Nov 18 2020, 07:18 PM Nov 18 2020, 07:18 PM

Show posts by this member only | IPv6 | Post

#105

|

All Stars

17,021 posts Joined: Jan 2005 |

QUOTE(aeiou228 @ Nov 18 2020, 04:39 PM) Hi, anyone can identify which L and N wires goes to Load? because there is no Load marking on the switch itself. I only see only L1, L2 and L3. If you switch ON and the red light is ON, than the wire from DB is bottom. (2nd pic)The white colour wire is incoming Live from the DB and I need to find out which is the incoming N and out going L and N that goes to the Load. PDL 20A switch

View from the bottom

View from the top

Cause the red light lamp attach to the TOP. This post has been edited by ozak: Nov 18 2020, 07:19 PM aeiou228 liked this post

|

|

|

Nov 19 2020, 11:07 PM Nov 19 2020, 11:07 PM

|

Senior Member

5,867 posts Joined: Feb 2006 |

QUOTE(ozak @ Nov 18 2020, 07:18 PM) If you switch ON and the red light is ON, than the wire from DB is bottom. (2nd pic) Like this ?Cause the red light lamp attach to the TOP.

Yes, the red light is lighted. So the small led wire should be connecting L (load) to N (load) right? This post has been edited by aeiou228: Nov 19 2020, 11:11 PM |

|

|

Nov 19 2020, 11:33 PM Nov 19 2020, 11:33 PM

|

All Stars

17,021 posts Joined: Jan 2005 |

|

|

|

Nov 26 2020, 11:55 PM Nov 26 2020, 11:55 PM

|

Senior Member

5,867 posts Joined: Feb 2006 |

QUOTE(ozak @ Nov 19 2020, 11:33 PM) Thank you sifu,Successfully replace the switch as per your guidance. ozak liked this post

|

|

|

Dec 10 2020, 05:59 PM Dec 10 2020, 05:59 PM

|

Junior Member

15 posts Joined: Mar 2006 |

Hi all,

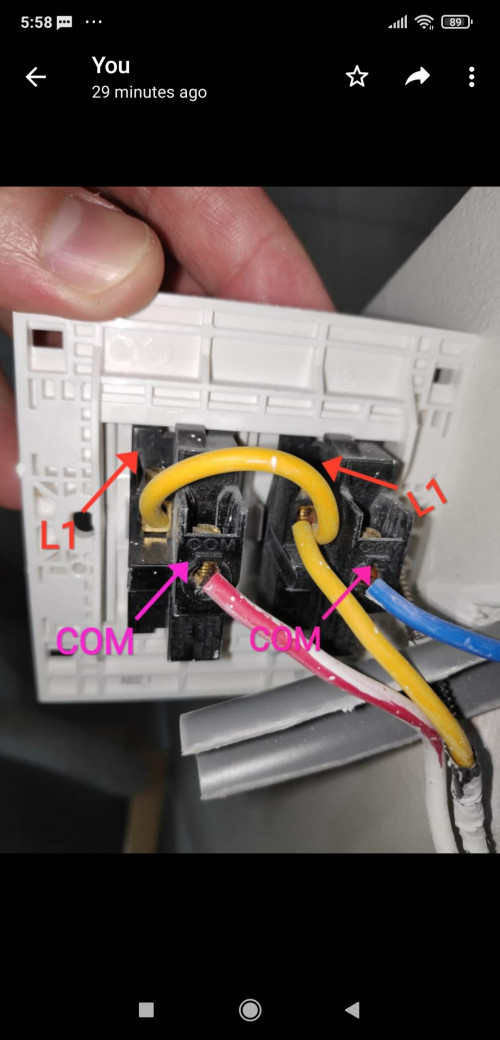

I have a noob questions to ask for help. I'm trying to figure out whether I can loop a power point for use like laptop or charge phone from existing light switch. Is that possible to add that? Or still need wiring like neutral and earth. Is a bit hard for me to get the neutral and earth wiring as it's all sealed inside a partition wall. Thanks in advance.    |

|

|

Dec 10 2020, 06:13 PM Dec 10 2020, 06:13 PM

|

Junior Member

15 posts Joined: Mar 2006 |

Duplicated.

This post has been edited by williamchiew: Dec 10 2020, 06:14 PM |

|

|

Dec 10 2020, 07:38 PM Dec 10 2020, 07:38 PM

|

Senior Member

3,355 posts Joined: Dec 2006 |

QUOTE(williamchiew @ Dec 10 2020, 05:59 PM) Hi all, Not possible, you only have live wire.I have a noob questions to ask for help. I'm trying to figure out whether I can loop a power point for use like laptop or charge phone from existing light switch. Is that possible to add that? Or still need wiring like neutral and earth. Is a bit hard for me to get the neutral and earth wiring as it's all sealed inside a partition wall. Thanks in advance.    williamchiew liked this post

|

|

|

Dec 10 2020, 07:39 PM Dec 10 2020, 07:39 PM

Show posts by this member only | IPv6 | Post

#112

|

Senior Member

1,132 posts Joined: Apr 2014 From: Shah Alam, Selangor |

QUOTE(williamchiew @ Dec 10 2020, 05:59 PM) Hi all, What you want to do (for all intents and purposes) is not possibleI have a noob questions to ask for help. I'm trying to figure out whether I can loop a power point for use like laptop or charge phone from existing light switch. » Click to show Spoiler - click again to hide... « williamchiew liked this post

|

|

|

Dec 10 2020, 08:35 PM Dec 10 2020, 08:35 PM

Show posts by this member only | IPv6 | Post

#113

|

All Stars

17,021 posts Joined: Jan 2005 |

QUOTE(williamchiew @ Dec 10 2020, 05:59 PM) Hi all, Without N and E, not possible.I have a noob questions to ask for help. I'm trying to figure out whether I can loop a power point for use like laptop or charge phone from existing light switch. Is that possible to add that? Or still need wiring like neutral and earth. Is a bit hard for me to get the neutral and earth wiring as it's all sealed inside a partition wall. Thanks in advance.    And the switch wiring also wrong connection. The COM should be L (yellow) and loop to another COM. Red and blue should be at L1 each. williamchiew liked this post

|

|

|

Dec 10 2020, 11:54 PM Dec 10 2020, 11:54 PM

|

All Stars

11,667 posts Joined: Jan 2003 From: Klang/Subang |

QUOTE(williamchiew @ Dec 10 2020, 05:59 PM) Hi all, Not possible. This L circuit at the switch doesn't provide return neutral and earth required for 13A socket there.I have a noob questions to ask for help. I'm trying to figure out whether I can loop a power point for use like laptop or charge phone from existing light switch. Is that possible to add that? Or still need wiring like neutral and earth. Is a bit hard for me to get the neutral and earth wiring as it's all sealed inside a partition wall. Thanks in advance.    The lights' N is connected only up to/at the light point. williamchiew liked this post

|

|

|

Dec 11 2020, 09:52 AM Dec 11 2020, 09:52 AM

|

Junior Member

15 posts Joined: Mar 2006 |

Thanks all for the advise.

The connection are done by contractor 🤭 I'll correct it back then, really appreciate for the comments! Thanks 🙏 |

|

|

Jan 7 2021, 04:48 PM Jan 7 2021, 04:48 PM

|

Senior Member

934 posts Joined: Mar 2009 |

|

|

|

Jan 7 2021, 10:55 PM Jan 7 2021, 10:55 PM

Show posts by this member only | IPv6 | Post

#117

|

All Stars

11,667 posts Joined: Jan 2003 From: Klang/Subang |

|

|

|

May 30 2021, 11:27 AM May 30 2021, 11:27 AM

|

Newbie

6 posts Joined: Oct 2008 From: Petaling Jaya |

Hi, I am facing an issue of identifying which wire color label. I am attempting to upgrade my Storage Water Heater switch to to Sonoff tx wifi smart wall switch. There are three colors Red, Blue & Black.

Sonoff TX Switch Manual: https://sonoff.tech/wp-content/uploads/2021....2-20210305.pdf Can anyone help me match the wiring to the diagram please. This post has been edited by jskhoo: May 30 2021, 11:30 AM |

|

|

May 30 2021, 11:43 AM May 30 2021, 11:43 AM

|

Senior Member

6,914 posts Joined: Apr 2007 |

QUOTE(jskhoo @ May 30 2021, 11:27 AM) Hi, I am facing an issue of identifying which wire color label. I am attempting to upgrade my Storage Water Heater switch to to Sonoff tx wifi smart wall switch. There are three colors Red, Blue & Black. you cant use that switch.   Sonoff TX Switch Manual: https://sonoff.tech/wp-content/uploads/2021....2-20210305.pdf Can anyone help me match the wiring to the diagram please. max rated output only 2 amp. water heater takes much more than that. |

|

|

May 30 2021, 11:50 AM May 30 2021, 11:50 AM

|

Newbie

6 posts Joined: Oct 2008 From: Petaling Jaya |

|

|

|

May 30 2021, 03:09 PM May 30 2021, 03:09 PM

|

All Stars

11,667 posts Joined: Jan 2003 From: Klang/Subang |

QUOTE(jskhoo @ May 30 2021, 11:50 AM) Is it? 3kw water heater need a 20A DP (double pole L+N);What should be the power rating I need? Any suggestion of which Smart switch I would need for a storage water heater please? Thank you Else u need to wire up a contactor instead if you want to use original switch. A contactor allows a kancil to control the operation of a trailer load. |

|

|

Jun 1 2021, 10:22 AM Jun 1 2021, 10:22 AM

|

Newbie

6 posts Joined: Oct 2008 From: Petaling Jaya |

|

|

|

Jun 1 2021, 08:43 PM Jun 1 2021, 08:43 PM

|

Newbie

6 posts Joined: Oct 2008 From: Petaling Jaya |

QUOTE(jskhoo @ May 30 2021, 11:27 AM) Hi, I am facing an issue of identifying which wire color label. I am attempting to upgrade my Storage Water Heater switch to to Sonoff tx wifi smart wall switch. There are three colors Red, Blue & Black. Forgot to ask, could anyone help me identify which wire is Live(IN), Live(OUT), Neutral?   Sonoff TX Switch Manual: https://sonoff.tech/wp-content/uploads/2021....2-20210305.pdf Can anyone help me match the wiring to the diagram please.  Thank you |

|

|

Jun 1 2021, 08:58 PM Jun 1 2021, 08:58 PM

|

All Stars

11,667 posts Joined: Jan 2003 From: Klang/Subang |

QUOTE(jskhoo @ Jun 1 2021, 08:43 PM) Blue LINE (always ON regardless)and the black to its 3 o clock is N Red LOAD (switched ON/OFF) (based on LED). and the black to red 3 o cllck is N Confirm with test pen or multimeter because the previous installer is color blind. Never trust the colour. Bangla tarak wireman cert one. This post has been edited by ceo684: Jun 1 2021, 10:05 PM |

|

|

Jun 2 2021, 08:35 PM Jun 2 2021, 08:35 PM

|

Newbie

6 posts Joined: Oct 2008 From: Petaling Jaya |

QUOTE(ceo684 @ Jun 1 2021, 08:58 PM) Blue LINE (always ON regardless) Thanks so much for the clarification. and the black to its 3 o clock is N Red LOAD (switched ON/OFF) (based on LED). and the black to red 3 o cllck is N Confirm with test pen or multimeter because the previous installer is color blind. Never trust the colour. Bangla tarak wireman cert one. Yeah I agree that the person who worked on it obviously didn't do a correct job on the wiring. |

|

|

Jan 30 2022, 03:22 PM Jan 30 2022, 03:22 PM

Show posts by this member only | IPv6 | Post

#126

|

Junior Member

88 posts Joined: Jan 2003 From: Penang |

|

|

|

Jan 30 2022, 03:29 PM Jan 30 2022, 03:29 PM

|

All Stars

17,021 posts Joined: Jan 2005 |

|

|

|

Jan 30 2022, 03:55 PM Jan 30 2022, 03:55 PM

Show posts by this member only | IPv6 | Post

#128

|

Junior Member

202 posts Joined: Mar 2020 |

|

|

|

Jan 30 2022, 04:00 PM Jan 30 2022, 04:00 PM

Show posts by this member only | IPv6 | Post

#129

|

Junior Member

88 posts Joined: Jan 2003 From: Penang |

QUOTE(ozak @ Jan 30 2022, 03:29 PM) Usually is blue. OK. Thanks for advice. If you want to confirm, take out the DB box cover. Check what color the wire that connect all together on the terminal. That is neutral. I just tried to open up another wall socket to check. This one has yellow / black / green. So, I can assume black is common colour for neutral, and yellow is Live as it's connected to the live terminal of the socket. Black should be common colour for Neutral line then. Was confused because I always remember guideline for Brown / Blue / Green in the past which were Live / Neutral / Ground respectively. Blue was neutral. Probably colour scheme updates to accommodate 3-phase power supply network?  |

|

|

Jan 30 2022, 04:46 PM Jan 30 2022, 04:46 PM

|

All Stars

17,021 posts Joined: Jan 2005 |

QUOTE(EvOliver @ Jan 30 2022, 04:00 PM) OK. Thanks for advice. Brown/ blue/green wire code is for electrical appliances. I just tried to open up another wall socket to check. This one has yellow / black / green. So, I can assume black is common colour for neutral, and yellow is Live as it's connected to the live terminal of the socket. Black should be common colour for Neutral line then. Was confused because I always remember guideline for Brown / Blue / Green in the past which were Live / Neutral / Ground respectively. Blue was neutral. Probably colour scheme updates to accommodate 3-phase power supply network?  For house wiring, doesn’t follow this code. If 3phase incoming, red/blue/yellow is using and black is neutral. The only color that all what kind of code have to follow is the green for earth. |

|

|

Jan 30 2022, 04:57 PM Jan 30 2022, 04:57 PM

Show posts by this member only | IPv6 | Post

#131

|

Junior Member

88 posts Joined: Jan 2003 From: Penang |

QUOTE(ozak @ Jan 30 2022, 04:46 PM) Brown/ blue/green wire code is for electrical appliances. Right. So in this case, can't really assume Black is usual Live. Have to really verify, either by reference connection, or by test pen, to be sure.For house wiring, doesn’t follow this code. If 3phase incoming, red/blue/yellow is using and black is neutral. The only color that all what kind of code have to follow is the green for earth. |

|

|

Jan 30 2022, 05:14 PM Jan 30 2022, 05:14 PM

|

All Stars

11,667 posts Joined: Jan 2003 From: Klang/Subang |

QUOTE(EvOliver @ Jan 30 2022, 04:57 PM) Right. So in this case, can't really assume Black is usual Live. Have to really verify, either by reference connection, or by test pen, to be sure. Generally in MY the code colours black is never L regardless flexicord or stiff (solid stranded) wire.However there's a lot of champion never follow proper colour code. Assume installer is colour blind and test to be sure. ⚠️ There is a possibility idiota installed L and N terbalik. Pls test to be sure. IN-WALL 230V wiring colour code typically L red yellow blue, sometimes even white 🤦♀️ N is black E is green This post has been edited by ceo684: Jan 30 2022, 06:49 PM |

|

|

Jan 30 2022, 05:17 PM Jan 30 2022, 05:17 PM

|

All Stars

11,667 posts Joined: Jan 2003 From: Klang/Subang |

QUOTE(IMF2025 @ Jan 30 2022, 03:55 PM) Ini terbalik. Black is usually neutral in MY. Overseas code lain cerita. |

|

|

Jan 30 2022, 05:27 PM Jan 30 2022, 05:27 PM

|

All Stars

17,021 posts Joined: Jan 2005 |

QUOTE(EvOliver @ Jan 30 2022, 04:57 PM) Right. So in this case, can't really assume Black is usual Live. Have to really verify, either by reference connection, or by test pen, to be sure. Follow as what I write on top how to verify.Take out the DB box front cover. You can see a bunch of wire connect together on the terminal. Earth and neutral. From here you can know what color wire for the neutral. |

|

|

Jan 30 2022, 10:19 PM Jan 30 2022, 10:19 PM

Show posts by this member only | IPv6 | Post

#135

|

Junior Member

88 posts Joined: Jan 2003 From: Penang |

Actually, I'm looking for a standardised spec for Malaysia power line colour code. Everyone should follow the same standard to avoid confusion nor misunderstanding.

|

|

|

Jan 30 2022, 10:37 PM Jan 30 2022, 10:37 PM

Show posts by this member only | IPv6 | Post

#136

|

Junior Member

88 posts Joined: Jan 2003 From: Penang |

Yes, I've monitored a foreigner contractor installing LED ceiling lights before. One out of several lights, he actually tested one light and tripped the power. He happened to connect earth line to LEDs neutral terminal. 🤦♂️ Can't imagine how many connection mistakes could have been hidden from owners' view without knowing. Reversed Live and Neutral connection may be another hidden danger.

|

|

|

Jan 31 2022, 12:42 AM Jan 31 2022, 12:42 AM

Show posts by this member only | IPv6 | Post

#137

|

All Stars

11,667 posts Joined: Jan 2003 From: Klang/Subang |

QUOTE(EvOliver @ Jan 30 2022, 10:19 PM) Actually, I'm looking for a standardised spec for Malaysia power line colour code. Everyone should follow the same standard to avoid confusion nor misunderstanding. It's in MS1979 spec and ST guidelines. Item 5.5Attached File(s)  ST_Guidelines_For_Electrical_Wiring.pdf ( 427.2k )

Number of downloads: 79

ST_Guidelines_For_Electrical_Wiring.pdf ( 427.2k )

Number of downloads: 79 EvOliver liked this post

|

|

|

Jan 31 2022, 02:45 AM Jan 31 2022, 02:45 AM

Show posts by this member only | IPv6 | Post

#138

|

Junior Member

88 posts Joined: Jan 2003 From: Penang |

|

|

|

Jan 31 2022, 04:37 PM Jan 31 2022, 04:37 PM

|

Senior Member

3,032 posts Joined: Jan 2003 |

Electrical wire colour code is only reliable if its practiced at the main DB first. Test pen can't differentiate Earth vs Neutral. Multimeter is the better tool. E & L = 230VAC E & N = As close to 0VAC as possible, 1-2VAC is fine. Anything higher indicates improper wiring/installation L & N = 230VAC Majority of electricians rely on test pen. The minorities don't bother to use one as they don't understand E & N difference. ceo684 liked this post

|

|

|

Jan 31 2022, 09:44 PM Jan 31 2022, 09:44 PM

Show posts by this member only | IPv6 | Post

#140

|

All Stars

11,667 posts Joined: Jan 2003 From: Klang/Subang |

QUOTE(louyeh @ Jan 31 2022, 04:37 PM) Electrical wire colour code is only reliable if its practiced at the main DB first. Sometimes with champion faux electrician the code is only followed up to the first light.. then switch relocated + new lights added in same line due to plaster ceiling what you see at the switch and other lights will surprise you.Test pen can't differentiate Earth vs Neutral. Multimeter is the better tool. E & L = 230VAC E & N = As close to 0VAC as possible, 1-2VAC is fine. Anything higher indicates improper wiring/installation L & N = 230VAC Majority of electricians rely on test pen. The minorities don't bother to use one as they don't understand E & N difference. |

|

|

Feb 2 2022, 12:26 AM Feb 2 2022, 12:26 AM

Show posts by this member only | IPv6 | Post

#141

|

Junior Member

88 posts Joined: Jan 2003 From: Penang |

QUOTE(louyeh @ Jan 31 2022, 04:37 PM) Electrical wire colour code is only reliable if its practiced at the main DB first. How to differentiate N and E by DMM?Test pen can't differentiate Earth vs Neutral. Multimeter is the better tool. E & L = 230VAC E & N = As close to 0VAC as possible, 1-2VAC is fine. Anything higher indicates improper wiring/installation L & N = 230VAC Majority of electricians rely on test pen. The minorities don't bother to use one as they don't understand E & N difference. |

|

|

Feb 2 2022, 12:49 AM Feb 2 2022, 12:49 AM

|

All Stars

11,667 posts Joined: Jan 2003 From: Klang/Subang |

|

|

|

Feb 2 2022, 05:27 AM Feb 2 2022, 05:27 AM

|

Senior Member

3,032 posts Joined: Jan 2003 |

Earth = 0 volts, dead zero, the more zeroes the better.

Neutral = Will have very low VAC reading, it is never 0 volts AC, 0.5VAC isnt zero volts. It can be high reading like 5 or 10 VAC which isn't good since it adds up to the AC phase. Henceforth test pen is a quick and useless tool to tell apart Earth & Neutral. That is the only reason why some see no difference in wiring until the mains is switched on. The test pen will never light up on a Neutral since its so low voltage. Also be mindful that the test pen will light up with relatively low voltage, ie 50VAC. Do be cautious if you are not trained & experience in measuring live voltage. |

|

|

Feb 2 2022, 11:11 AM Feb 2 2022, 11:11 AM

|

Senior Member

1,132 posts Joined: Apr 2014 From: Shah Alam, Selangor |