QUOTE(lichyetan @ Sep 4 2008, 10:48 PM)

oh... my D5 is MCP655-B which the version without the speed control, so its basically the basic version, its rated at speed 4 of the mcp655, and also D4 is actually same spec as MCP655-B, cause if u notice, MCP655 have higher head pressure thn MCP-655B so as to D4...

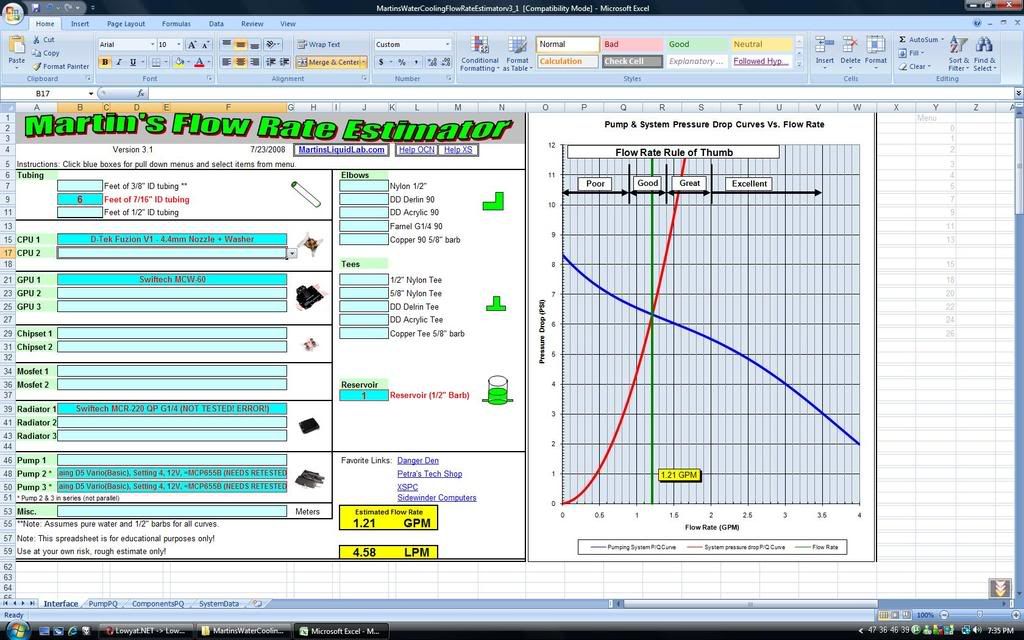

yup, i know its overall flowrate... but to get overall cooling correct, average flowrates also takes into account rite ? i mean if cpu block functioning at optimal range, my gpu block might suffer or my radiator didnt work as efficient as higher overall flowrate rite ?

I've been thinking to get the DDC3.2 before, but due to its reliability problem, i gave up the plan and ended up on dual pumps(D4 & D5 basic).

about the nozzle kit, martins over at xtremesystem there tell me to give up 4.4mm and use the larger nozzle instead if running multiple block... but its all about overall performance, if wan more perfomance on the cpu block, 5.5 and 4.4 mm are the choice, if wan overall performance of the whole loop, use washer only instead of nozzles...

so the main reason pushing me for dual inline pump is i want the 4.4mm nozzle yet wanted to use more restricitive mp-01(compare to MCW-60, i dont like the mounting style of mcw-60 to be honest) on my gpu, so ended up bought another D5 basic to pair with my original D4 to gain higher overall flow...

*addons:

isnt dual pump give us more safer loop, i mean if one pump dead(*touchwood) the CPU wont overheat as the backup pump still running rite ? its more redundant setup rite ? just my idea, dunno whether u all agree onot...

It's getting late and I still work tomorrow but here we go

The overall flow rate calculation is an average, not displaying effective flow rate at entry of waterblock and post block.. What I'd rather do is to use the use the chart to calculate what's the flow rate post block. That's how I worked out your flow rate. That's the figure post outlet of your fuzion and if that's good enough for your MCP60, then it should be fine. That's how I view the table's usefulness.

As for the nozzle kit, you have to ask yourself how much your willing to give up just for that extra squeeze. I'd say for such a short and very low pipe restriction due to minimal bend, you might be better off without the nozzle. At such length, it's likely you're still getting laminar flow so you're having jet effect at inlet. That nozzle might worsen things since at such length, it might be just causing back pressure, hence reducing effective flow and effective head pressure at inlet. that nozzle imho would suit best for normal nearly 1ft length arcing tubing in ATX casings since by about 8-9", the flow would be experiencing turbulent flow internally hence slow down of flow rate thanks to turbulence resistance and wall friction combined. That's where the nozzle's purpose kicks in as it accelerates the slowed down water flow. Because remember, the Fuzion still utilises a flow thru method where flow rate is more important then flow thru pressure. Flow thru pressure only applies for jetting based blocks

I agree with the MCW60's mounting method being a pain but it's not much different then mounting any normal waterblock if you asked me. In the end, you have to really ask yourself, at what cost are you going to pay to get the best? Would it be the cash spent experimenting the various blocks or the time and effort to tweak and tweak to get that edge?

Dual pump not necessary safer to be honest. You want safe? Go AC based instead, the ultimate in safety (Japan made Iwaki's anyone? LOL). At least you know the bugger works or not before you power up. And the DDC 3.2's problem you wanna know why? Very simple really. It's a finely engineered pump which utilises the 3 pin connection for mobo's. The problem with that is that these motors bloody hate variating voltage rates which mobo outputs are notorious for. Feed it with clean current at a fixed rate and it'll work for quite sometime.

IF you wanna really learn liechy, I'd suggest you'd take some time and get your hands dirty in experimenting various setups until you get your best setup. And you have to try every variable down to mounting technique and thermal paste application. Trust me, the biggest tweaks lie in the least likely places

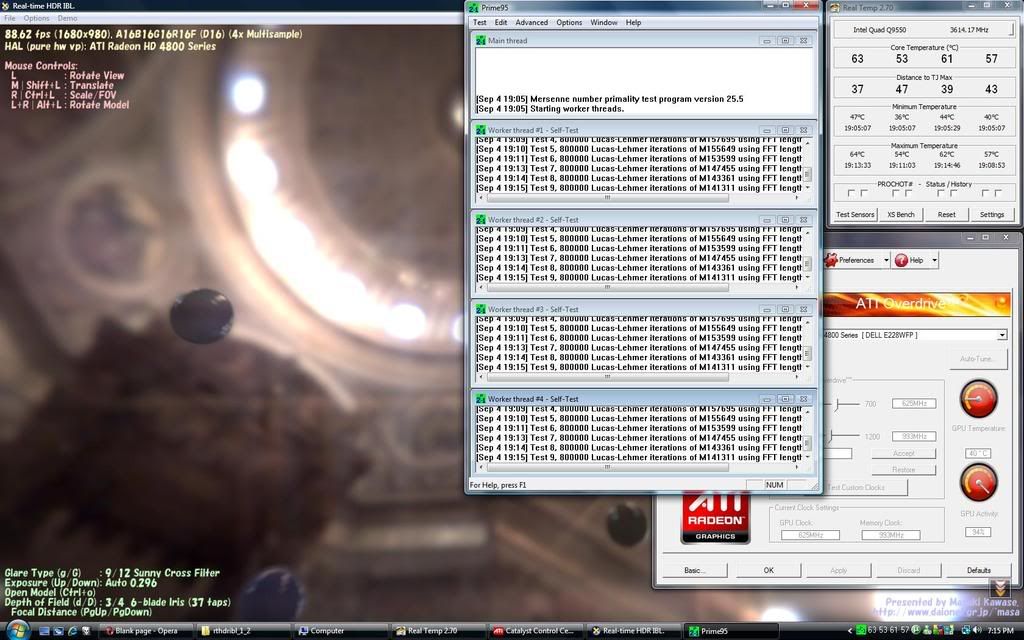

and BTW, I know how your rigs looks like because of this

and I was away ahead of you guys

This was back when Athlon XP ruled

This post has been edited by almostthere: Sep 5 2008, 12:38 AM

This post has been edited by almostthere: Sep 5 2008, 12:38 AM  i think of changing water in my system also

i think of changing water in my system also  eh my tubing seems to cloud pretty quickly eh.. why is that?... i just cleaned last month... algae stuck to the wall of of tubing..

eh my tubing seems to cloud pretty quickly eh.. why is that?... i just cleaned last month... algae stuck to the wall of of tubing..

Sep 3 2008, 01:22 PM

Sep 3 2008, 01:22 PM

Quote

Quote

0.0339sec

0.0339sec

0.80

0.80

6 queries

6 queries

GZIP Disabled

GZIP Disabled