#Construction #Brickwork

Welcome back to the sharing session today! We will talk about the basic brickwork construction in this industry. We are glad that we are able to guide you steps by steps on how we work from start to end. As mentioned earlier, the more you know, the easier for you to monitor the entire working process to assure quality!

The method statement below simplified all of the important steps, and I hope you learn something today:

1. Firstly, fix the location and position of the brickwork by setting out the reference line.

2. Confirm the allowance of openings with other trade contractors such as aluminium & glazing contractor, plumber etc. Initial planning and locate the service pipe sleeves / provision of openings are needed.

3. Inspection of bricks are conducted to ensure all of the materials are in good condition. Damaged masonry units are not allowed to be used.

4. Mix mortar to the proportion.

5. Transport the mixed mortar to brick laying area with wheelbarrow.

6. Bricks are firstly soaked in water for at least half an hour to gain moisture.

7. Clean the supporting surfaces and remove loose mortar before start laying.

8. Stiffener shall be provided at every 3m in both horizontal and vertical directions as long span of brickworks are unable to retain its strength. The bricks should be tied back to the RC structure.

9. Place the mortar onto the bricks with spatula.

10. Lay the bricks layer by layer with 10mm gap of joints.

11. Use a plumb and spirit level to control the verticality.

12. Place expanded metal reinforcement mesh every 4th course of bricks to increase the reinforcement strength.

13. Starter bar / Brick ties secured to the stiffener / column shall be provided every 4th course of brickwork. Both expanded metal reinforcement & brick ties shall be embedded completely in mortar.

14. Supervisor shall inspect the quality of works upon completion, sign off or rectify the non-quality works.

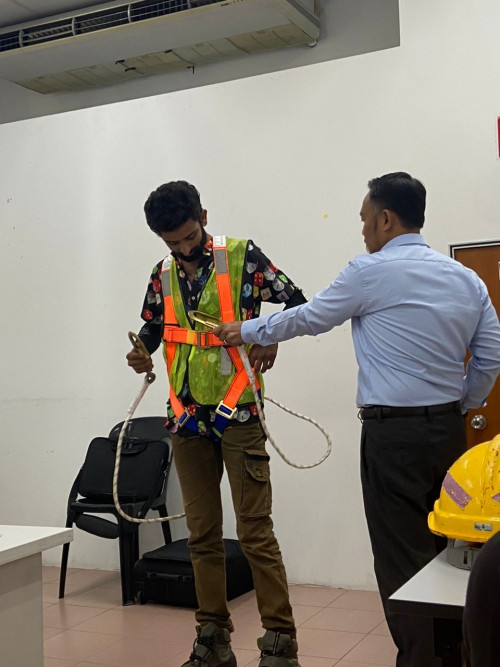

Protective measures:

1. Material shall be kept as cool as possible to avoid the masonry units from absorbing the water from mortar, which result in cracking.

2. Masonry unit shall be placed on top of mortar during laying.

3. Use fog spray / wall covering to ensure sufficient moisture retain on the brickwork during curing.

4. Cover the wall after construction to slow down the rate of water loss from masonry.

Additional tips:

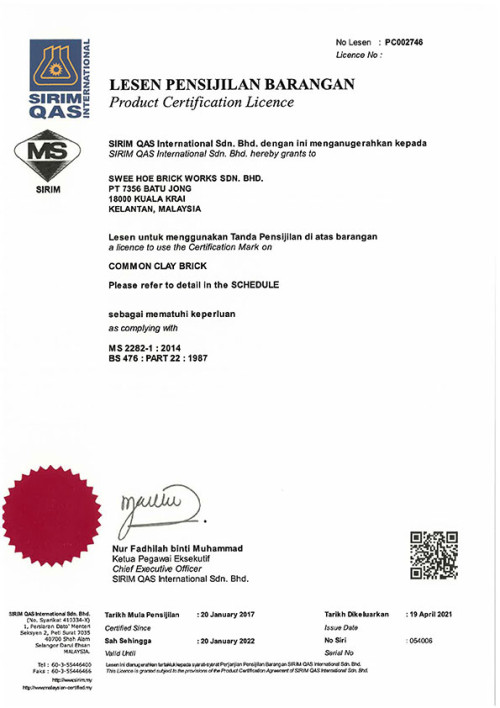

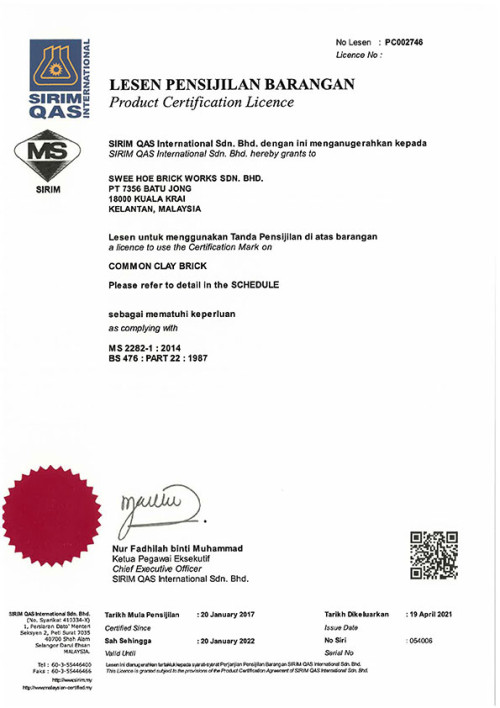

1. SIRIM certificate with test report are always requested from during approval of material to ensure the building materials submitted are qualified to be use.

2. Certain Malaysian Standard requirement test are introduced to monitor the compressive strength, initial rate of water absorption, dimension and tolerance of brick units.

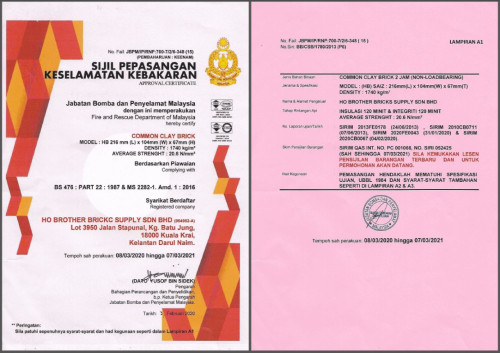

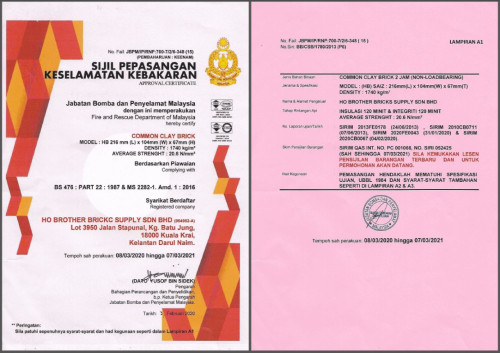

3. It shall always comply to fire test requirement – “Sijil Pepasangan Keselamatan Kebakaran” in order to prove the material properties.

Mar 9 2023, 10:57 AM

Mar 9 2023, 10:57 AM

Quote

Quote

0.0342sec

0.0342sec

0.55

0.55

6 queries

6 queries

GZIP Disabled

GZIP Disabled