As an industry, overall indonesian aerospace is small when compared to malaysia, even if it can build whole aircraft like CN-235, of which only the metal airframe is locally built, all the engines, avionics, radars, communications, hydraulic systems, even most of the raw materials is fully imported. Annually it manufactures less than 4 CN-235. Since 2012 PTDI has build just around 60 aircrafts, that number includes final assembly of helicopters from 100% overseas components for indonesian military.

https://www.channelnewsasia.com/commentary/...s-di-rai-872466QUOTE

In 2017, Indonesia’s aerospace exports only reached US$103.9 million, while Singapore and Malaysia’s exports reached US$7.4 billion and US$2.1 billion, respectively.

.

Malaysia for RMK12, has underlined the aerospace industry as one of the main priorities.

https://www.nst.com.my/business/2021/09/731...ace-sector-12mp

https://www.nst.com.my/business/2021/09/731...ace-sector-12mpQUOTE

Aerospace is a globalised industry with exacting and uncompromising standards. It is a gateway industry to other higher value sectors such as high-end medical devices and robotics.

Malaysia has long established an aerospace industry ecosystem. Through the 12th Malaysia Plan (12MP) from 2021-2025, we are bolstering our position among the key players in Asia Pacific.

The country's aerospace industry supply chain consists of design and engineering services, aerospace manufacturing, maintenance, repair and overhaul (MRO) services as well as training for students and professionals.

Aerospace manufacturing and MRO services are the most dominant in Malaysia, contributing to more than 90 per cent of the industry revenue.

There are now more than 240 aerospace-related companies operating here, comprising both local and global players. The industry has generated more than 25,000 skilled jobs, of which 95 per cent are locals. The aerospace industry is among the leading industries in Malaysia embracing 4IR (fourth industrial revolution) technology.

Major global players have established their regional centre in Malaysia to serve the growing Asia Pacific market. This includes Airbus' regional engineering support centre for all of Asia except China, and GE Aviation.

The latter, through GE Engine Services Malaysia, is the only GE Aviation full overhaul centre in Asia Pacific.

Similarly, our local aerospace industry is designing and producing parts and components that move on the back of the wing, in the cockpits and fuselages of global carriers' aircraft. Malaysia in fact is among the world's largest aircraft components manufacturers.

Propelling Malaysia's aerospace industry

Developed countries such as the United States of America, South Korea, China, Japan and Singapore have strong aerospace industries at the core of their innovation economies.

South Korea, for example, is a significant producer of aerospace technology, producing their own T-50 fighter jets. The country is also globally dominant in the E&E (electrical and electronics) and M&E (machinery and equipment) sectors with conglomerates like Hyundai and LG both having aerospace divisions among their technology development drivers.

Propelling Malaysia's aerospace industry in the 12MP brings a new set of challenges and opportunities given the disruption and uncertainties brought about by the pandemic.

The International Air Transport Association expects global travel to return to pre-pandemic levels between 2023 and 2024, with regional travel being the main driving force. Global OEMs expect the commercial aircraft market to gradually recover between 2023 and 2025.

After this point, the OEMs anticipate an increase in orders on top of the delivery of backlog orders. It is forecasted that the demand for new commercial aircraft will be geared towards fuel-efficient aircraft and will be dominated by single-aisle jets for short-haul routes as well as for air cargo, defense and space sectors.

The pandemic has adversely affected the global aerospace sector. However, we should prepare ourselves for the future. The 12MP is an opportune time for us to do just that.

Interestingly enough, the Malaysian supply chain has seen more requests for quotations (RFQs) during the pandemic, reflecting adjustments in the global supply chain favouring the country. Thus, it is crucial to ensure that the local aerospace industry is supported throughout this pandemic to sustain its skills and competencies, as well as grow its technology and innovation capabilities.

The triple helix partnership between industry, government and academia will be strengthened under the 12MP to accelerate the digitalisation and automation of the supply chain as part of its Industry 4.0 transformation.

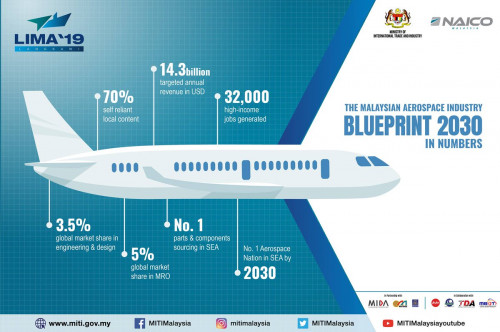

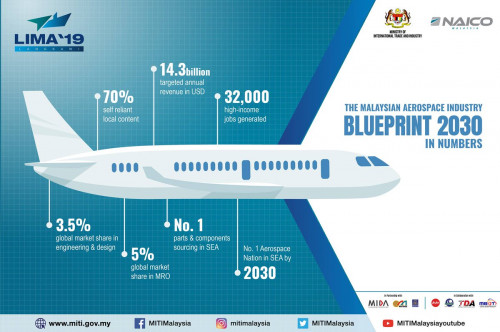

A more coordinated strategy among industry stakeholders is crucial in ensuring the goals of the Malaysia Aerospace Industry Blueprint 2030 are achieved. Enhancement of the industry's institutional capacity is then anticipated to propel growth.

Training and other industry catalysts

Covid-19 and emerging climate change requirements are forcing companies like Airbus and Boeing to develop more environmentally-friendly aircrafts and engines.

The development of Airbus' zero-emission hybrid-hydrogen commercial aircraft known as ZEROe and Boeing's ecoDemonstrator 787 harnesses the power of big data for real time efficient flying. Thus, Malaysia's capabilities in this sustainable aviation area needs to be mobilised considering biofuels and hydrogen are already beginnig to gain a more important role.

Additionally, Malaysia has several public universities with strong aerospace engineering capabilities, particularly in testing new aerodynamic designs as well as in mechanical and electrical engineering.

Our TVET colleges today are already producing some of the region's most high skilled aerospace technicians. Nonetheless, education and industrial training through the triple helix approach should be given more focus in building up the necessary skills for future industrial needs.

Over the years, Malaysia has strengthened its position as a key player in the regional aerospace industry. From the setting up of Malaysia Airlines' engineering and maintenance facilities in 1972 to the establishment of UMW Holdings Bhd's aerospace manufacturing engine components for Rolls Royce in 2015 and the recent domination of Aerodyne Sdn Bhd in global drone services, we are becoming major players.

Aerodyne, a homegrown company, is already the second largest drone technology company in the world, providing services to the telecommunications, energy, infrastructure, agriculture and transportation industries in more than 20 countries.

Aerodyne is an example of how new emerging and disruptive aerospace sub-sectors like drone services and satellite internet are creating new opportunities for revenue and employment.

The aerospace industry will play a catalytic role in the nation's economic recovery by spearheading Industry 4.0 transformation and creating new economic opportunities.

Going forward, aerospace is just one of many industries that the country will have to focus on, in order to become a high-income nation. The 12th Malaysia Plan will facilitate this industry, among many others, to harness its strengths and reduce its inefficiencies.

*The writer is the Minister in the Prime Minister's Department in charge of economy

.

https://www.astroawani.com/berita-malaysia/...nue-2025-322062QUOTE

The aerospace industry has been identified as one of the strategic industries under the 12th Malaysia Plan (12MP) to propel the country into the high technology trajectory, generating RM30 billion revenue by 2025 from RM11.6 billion in 2020.

According to the 12MP document released by the Economic Planning Unit (EPU) today, the industry, which is projected to create 30,000 jobs over the next five years, would be transformed to produce more complex products and services.

Oct 5 2021, 09:55 PM

Oct 5 2021, 09:55 PM

Quote

Quote

0.0376sec

0.0376sec

0.51

0.51

6 queries

6 queries

GZIP Disabled

GZIP Disabled