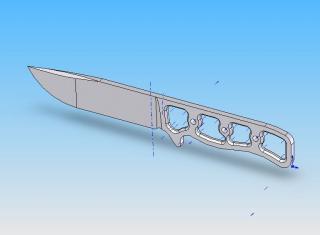

Thanks. A lot of thought/engineering went into this. The guy who did it was a former Lotus Engineering design engineer and also a tool and die maker/designer. He now works on designing oil rig tooling & equipment. This whole thing started when his brother looked up and was obsessed with the Fallkniven A1, RAT-7, Chris Reeve/Bill Harsey Green Beret, Mission MPK-S, Mad Dog ATAK, Randall Model 14, Cold Steel SRK and told this designer guy what he wanted.

1) 6" or 7" blade lengths. Shorter for better control. Longer for military requirements.

2) False edge to give more penetration.

3) Skeletonised handle with extreme chamfering to remove mass and move the balance point further up. Its about midway now on the 6". Should be further up on the 7".

4) Full tang construction.

5) Canvas phenolic or clear plastic side scales. Not sure which but the clear ghost view made me think of Blade Runner - Deckard's pistol.

6) Strong 1/4" thick tool steel - 1095, D2 or whatever else that's good and can be procured.

7) Glass breaker rear. You can hammer it down and crack stuff.

8) Rear thong hole.

9) Exposed tang rear (pommel) for batoning/pounding.

10) Field design, with one edge and no stress risers (wire cutters, serrations, etc. . . . )

11) The knife should hold an edge, yet be tough.

I've not found a good source of steel yet. Once I do then I can build a prototype and test, and perhaps make refinements IF necessary. The grinding and heat treatment, as well as the sheath need to be good. This is the first effort of an automotive/tool&die/oil&gas designer for a knife. It was done completely on Solidworks 3D after-office hours back home in Sandvika, Norway. I daresay he has done a good job.

Jul 1 2008, 11:05 AM

Jul 1 2008, 11:05 AM

Quote

Quote

0.0194sec

0.0194sec

0.60

0.60

6 queries

6 queries

GZIP Disabled

GZIP Disabled