Attached thumbnail(s)

Hobbies The Bleeding Edge, Discussion on all genres of knife

|

|

Jun 30 2008, 01:55 AM Jun 30 2008, 01:55 AM

Return to original view | Post

#1

|

Junior Member

448 posts Joined: Jan 2008 |

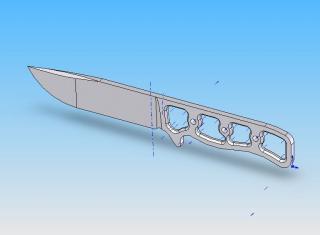

Speaking of handmade custom knives, here's a VERY early draft of the drawing. LOTS more radiuses, angles, etc. to be put into the whole thing. LOTS more work to be done. It's being drawn up in Norway by a former Lotus Engineering engineer who was also a tool & die designer. Handle scales could be either chengal wood or canvas phenolic. Thickness: 1/4".

Attached thumbnail(s)

|

|

|

|

|

|

Jul 1 2008, 11:05 AM Jul 1 2008, 11:05 AM

Return to original view | Post

#2

|

Junior Member

448 posts Joined: Jan 2008 |

Wow it seems at least 4 people I know are now interested in buying the handmade custom. I'll have to test out the prototype first. Crusader you bought that Extrema Ratio via internet? Any customs hassles?

|

|

|

Jul 1 2008, 11:26 AM Jul 1 2008, 11:26 AM

Return to original view | Post

#3

|

Junior Member

448 posts Joined: Jan 2008 |

As long as it is in your checked in luggage it should be fine I guess.

|

|

|

Jul 1 2008, 11:50 AM Jul 1 2008, 11:50 AM

Return to original view | Post

#4

|

Junior Member

448 posts Joined: Jan 2008 |

|

|

|

Jul 8 2008, 09:19 PM Jul 8 2008, 09:19 PM

Return to original view | Post

#5

|

Junior Member

448 posts Joined: Jan 2008 |

Anyone know who can do a proper stock removal, grind, heat treat and final honing job on a 1/4" steel stock to make a custom to my drawings? I'm in KL. PM me if you like. The drawing above was done in Solidworks in Sandvika, Norway by a former Lotus Engineering design engineer. The handle has been skeletonised and extreme chamfering added to lighten it and move the centre of gravity up towards the blade itself. Lanyard holes not done yet. Glass breaker exposed tang rear not done yet. This post has been edited by BikerVoodoo: Jul 9 2008, 07:11 AM |

|

|

Jul 9 2008, 07:30 AM Jul 9 2008, 07:30 AM

Return to original view | Post

#6

|

Junior Member

448 posts Joined: Jan 2008 |

|

|

|

|

|

|

Jul 9 2008, 10:55 PM Jul 9 2008, 10:55 PM

Return to original view | Post

#7

|

Junior Member

448 posts Joined: Jan 2008 |

QUOTE(ipodluvya @ Jul 9 2008, 05:39 PM) I'm in Cheras, KL. The former Lotus Engineering design enginer (before that he was a tool & die engineer, tool & die diploma best student award winner, etc.) is working on this full tang blade design. Have more or less found a source for D2 tool steel. He is continuing to refine the design at nights after work in Sandvika, Norway on SolidWorks 3D.You want one of these 'DMG1 Survival/Military' knives? |

|

|

Jul 15 2008, 01:14 PM Jul 15 2008, 01:14 PM

Return to original view | Post

#8

|

Junior Member

448 posts Joined: Jan 2008 |

|

|

|

Jul 17 2008, 12:53 AM Jul 17 2008, 12:53 AM

Return to original view | Post

#9

|

Junior Member

448 posts Joined: Jan 2008 |

Thanks. A lot of thought/engineering went into this. The guy who did it was a former Lotus Engineering design engineer and also a tool and die maker/designer. He now works on designing oil rig tooling & equipment. This whole thing started when his brother looked up and was obsessed with the Fallkniven A1, RAT-7, Chris Reeve/Bill Harsey Green Beret, Mission MPK-S, Mad Dog ATAK, Randall Model 14, Cold Steel SRK and told this designer guy what he wanted.

1) 6" or 7" blade lengths. Shorter for better control. Longer for military requirements. 2) False edge to give more penetration. 3) Skeletonised handle with extreme chamfering to remove mass and move the balance point further up. Its about midway now on the 6". Should be further up on the 7". 4) Full tang construction. 5) Canvas phenolic or clear plastic side scales. Not sure which but the clear ghost view made me think of Blade Runner - Deckard's pistol. 6) Strong 1/4" thick tool steel - 1095, D2 or whatever else that's good and can be procured. 7) Glass breaker rear. You can hammer it down and crack stuff. 8) Rear thong hole. 9) Exposed tang rear (pommel) for batoning/pounding. 10) Field design, with one edge and no stress risers (wire cutters, serrations, etc. . . . ) 11) The knife should hold an edge, yet be tough. I've not found a good source of steel yet. Once I do then I can build a prototype and test, and perhaps make refinements IF necessary. The grinding and heat treatment, as well as the sheath need to be good. This is the first effort of an automotive/tool&die/oil&gas designer for a knife. It was done completely on Solidworks 3D after-office hours back home in Sandvika, Norway. I daresay he has done a good job. |

|

|

Jul 18 2008, 12:46 AM Jul 18 2008, 12:46 AM

Return to original view | Post

#10

|

Junior Member

448 posts Joined: Jan 2008 |

I don't think titanium is a good material for a knife. Maybe for certain applications but not for real-world use.

|

|

|

Jun 3 2009, 12:56 AM Jun 3 2009, 12:56 AM

Return to original view | Post

#11

|

Junior Member

448 posts Joined: Jan 2008 |

Is there any knifemaker in Malaysia who can build my designs?

|

|

|

Jun 5 2009, 06:01 PM Jun 5 2009, 06:01 PM

Return to original view | Post

#12

|

Junior Member

448 posts Joined: Jan 2008 |

Look at the previous pages for my bro's design.

|

|

|

Dec 13 2009, 02:48 AM Dec 13 2009, 02:48 AM

Return to original view | Post

#13

|

Junior Member

448 posts Joined: Jan 2008 |

Here's an Emerson Mini CQC7 custom (Mini CQC6/CQC5 look) I just got. Titanium bolsters and liners I believe. Scales are micarta. IMHO this size is great for a pocketknife.

This post has been edited by BikerVoodoo: Dec 13 2009, 02:55 AM |

|

|

|

|

|

Feb 20 2010, 10:44 AM Feb 20 2010, 10:44 AM

Return to original view | Post

#14

|

Junior Member

448 posts Joined: Jan 2008 |

My friend just got a SOG SEAL Pup in from Canada. No probs with customs it just whizzed through. US$40 + US$30 for shipping. Arrived in 11 days. Very good knife, serrated edge is there too. Strong, sharp. Bang for buck. What more do you need?

|

|

|

Feb 20 2010, 11:32 AM Feb 20 2010, 11:32 AM

Return to original view | Post

#15

|

Junior Member

448 posts Joined: Jan 2008 |

Check out this Ebay store - http://stores.ebay.com/Wholesale-Knives-and-Swords?_rdc=1 Lots of other stuff there too. Why not get something bang for buck that you'll actually use. If the blade is too expensive you might be tempted to just use a parang and keep the knife as some sort of collectible and it will just gather dust.

|

|

|

Apr 25 2010, 11:55 PM Apr 25 2010, 11:55 PM

Return to original view | Post

#16

|

Junior Member

448 posts Joined: Jan 2008 |

I love my 7" blade tool steel (rusts!) survival blade. Hollow aluminium handle. Brass guard. |

|

|

Apr 26 2010, 06:05 AM Apr 26 2010, 06:05 AM

Return to original view | Post

#17

|

Junior Member

448 posts Joined: Jan 2008 |

|

|

|

Apr 27 2010, 06:02 AM Apr 27 2010, 06:02 AM

Return to original view | Post

#18

|

Junior Member

448 posts Joined: Jan 2008 |

|

|

|

Apr 27 2010, 08:47 AM Apr 27 2010, 08:47 AM

Return to original view | Post

#19

|

Junior Member

448 posts Joined: Jan 2008 |

|

|

|

Apr 27 2010, 12:01 PM Apr 27 2010, 12:01 PM

Return to original view | Post

#20

|

Junior Member

448 posts Joined: Jan 2008 |

|

| Change to: |  0.0396sec 0.0396sec

1.10 1.10

7 queries 7 queries

GZIP Disabled GZIP Disabled

Time is now: 27th November 2025 - 05:53 AM |