QUOTE(Zot @ Aug 25 2022, 03:11 PM)

Well, many electrical contractors charge too much but using low quality material. Most likely it is because they need to pay workers salary all year round and projects are not continuous all year long.

For that reason, I also prefer DIY

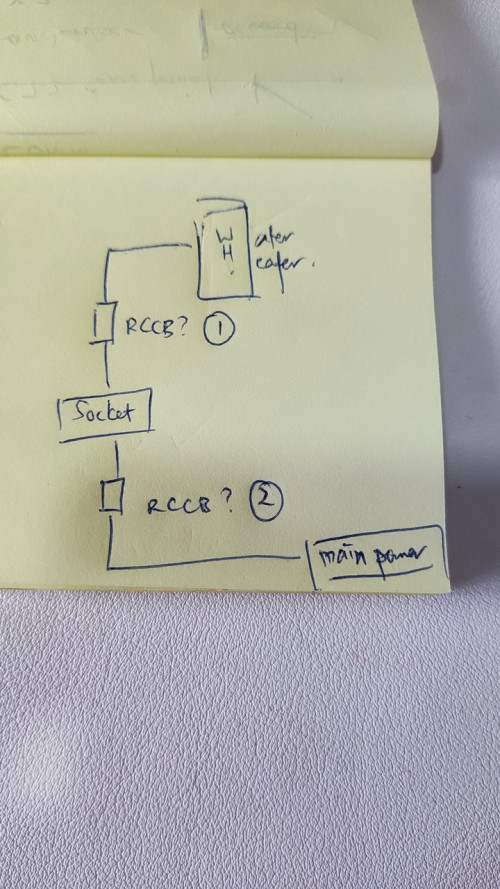

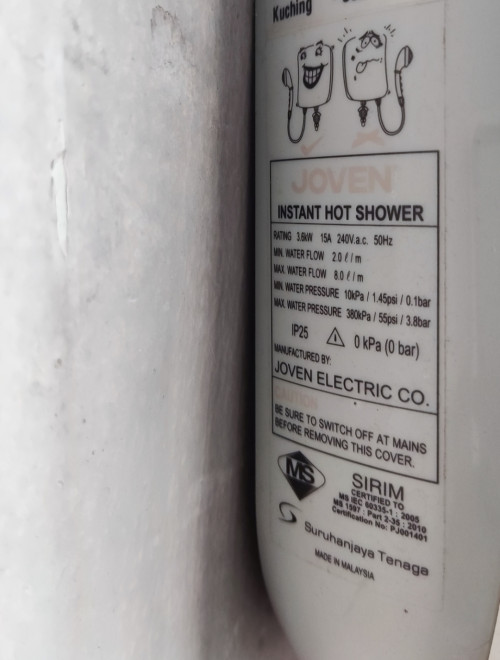

I'm not sure about the price because I'm not in this business line. However, if you talk about the manufacturing cost, ELCB is more expensive to produce compare to RCCB but the RCCB perform better than ELCB.

I guess the main reason for ELCB in appliances is detect faulty appliances

Also boils down to where it's made and currency exchange.

ABB/Hager 10mA made in Italy or France easily RM150-160/ea

Cheaper one local made or Schneider around RM100

Cheapest one from PRC around 60 bucks IIRC..

but u wanna save money on the "safety belt" device meh? Especially its "one-off payment life insurance"

as compared to whatever insurance every year pay a lot.. this one pay once covered for 20-30 years.

I also DIY because in that sense I know everything is fastened properly and according to spec or even some of the time, exceed spec (especially for short runs).. cable so cheap even for 4mm loose cut.. it won't break the bank. Its about not having to deal with melted wires or risk of house catching fire

For time saving and avoid breathing in plaster ceiling dust I also retrofit wago connectors for those LED downlights.. fiddling with screw connector is waste of my time when i can just clip unclip.

Hard to find clients that will insist to do it properly up to spec (safety is 1st priority) and don't mind paying (reasonable amounts).

This post has been edited by ceo684: Aug 25 2022, 06:30 PM

Aug 25 2022, 08:39 AM

Aug 25 2022, 08:39 AM

Quote

Quote

0.0269sec

0.0269sec

0.41

0.41

6 queries

6 queries

GZIP Disabled

GZIP Disabled