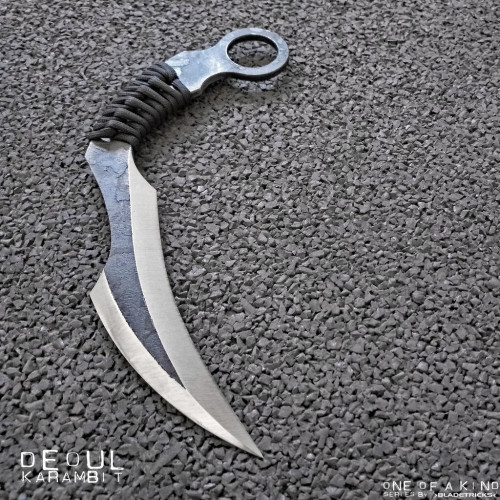

only the 2nd from top has an authentic/traditional karambit shape... the rest are much more unique in design.

the 4th & 5th last one in the list is particularly 'wow'

KNIFE MAKING - art for those who love steel craft, Interested in making edged tools/knives?

|

|

Dec 6 2019, 07:21 AM Dec 6 2019, 07:21 AM

Return to original view | Post

#61

|

Junior Member

104 posts Joined: Oct 2019 |

|

|

|

|

|

|

Dec 9 2019, 10:50 PM Dec 9 2019, 10:50 PM

Return to original view | Post

#62

|

Junior Member

104 posts Joined: Oct 2019 |

another weekend come & gone.

as was out this weekend - no 40 min quick mini project. ... prob will make it up next week wid sumtin major. |

|

|

Dec 9 2019, 10:59 PM Dec 9 2019, 10:59 PM

Return to original view | Post

#63

|

Junior Member

104 posts Joined: Oct 2019 |

i will also most probably conclude the smithing series posts next week & end it with the final stye of smithing.

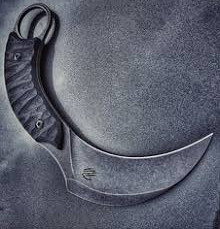

then move on to 'tools used for smithing' series. later followed prob by glossary of frequent used terms in smithing, etc. for now, we enjoy more delectable pix of unique karambits...   nice, unique curvy design. obviously double edged. very nice. differs greatly from the norm/traditional karambits. |

|

|

Dec 10 2019, 10:35 AM Dec 10 2019, 10:35 AM

Return to original view | Post

#64

|

Junior Member

104 posts Joined: Oct 2019 |

today we touch on the 5th and last power tool mentioned in the previous video featuring the 5 power tools - the dremel tool.

to be honest though - its actually a drill modded to act as a dremel. use em if u got em... else mod em till ur fine wid em another thing i noticed - i seem to be wrongly referring to the wu sifu video. ITS NOT THAT VIDEO. its the one after that using the 5 tools. please note. moving on, the dremel is a great lil tool. its greatly aids fine detailing and precision work. it usually/generally is referred to as a 'rotary tool'. as it relates to knife making, i generally use this machine to sand/shape wood handles, engrave steel & texturise metal and wood. it also has many other unique uses, all mostly focus on detailing, but since it has a tonne of attachments - u prob can use this multi tool for whatever u intend with the right attachment. for now, here's master craftsman (& forged in fire alumni!) walter again, providing info about this tool walter, as always, makes things easier for me by having to skip detailed explanations. gotta appreciate all he does for the smithing community check out this vid to see the super fine detailed work possible with a dremel & ogle at this video to see the tonnes of accessories & attachments available ... & of course there's links for how to make a diy dremel > https://www.youtube.com/results?search_query=diy+dremel and that ends the posts on the 5 tools used the previous video. we'll get back to the smithing videos here onwards. |

|

|

Dec 10 2019, 11:04 PM Dec 10 2019, 11:04 PM

Return to original view | Post

#65

|

Junior Member

104 posts Joined: Oct 2019 |

QUOTE(kabuto12 @ Dec 10 2019, 10:52 AM) too bad no asian edition.lookin forward to the day when a (probably) asian smith shows the judges how to PROPERLY do a burn through handle the right way. burn through handles are soooo super common in asia & easily done... maybe someday 1 of u guys will go compete & show them how easily its done |

|

|

Dec 13 2019, 01:55 PM Dec 13 2019, 01:55 PM

Return to original view | Post

#66

|

Junior Member

104 posts Joined: Oct 2019 |

to make up for last week's no weekend quick project - i will be doin something special this week.

it will definitely be unique. both, the actual end creation & process to make it will be very distinctive & off the beaten part. i'm looking forward to it. will try to showcase some very unique methods to create a very unique end tool to all who follow these posts/forum. it might be (probably is) a literal first documented process in world history of what i'm doing & the way its done, as try as i might, i cant find any documentation/video/online reference for what i'm about to do... too unique. probably a world first. stay tuned! |

|

|

|

|

|

Dec 21 2019, 03:11 PM Dec 21 2019, 03:11 PM

Return to original view | Post

#67

|

Junior Member

104 posts Joined: Oct 2019 |

QUOTE(posmaster @ Dec 16 2019, 04:20 PM) me and craft_coach have setup a watsapp chatgroup my welcome & thanks to postmaster. appreciate you handling the social media side of things This is for all guys or girls whom is interested in the art craft in the area of making steel knife, sword, keris, katana, steel items, wood work, making small home furniture, any artwork decoration using power tools... Feel free to PM me your telephone number and we will add you to tour watsapp group.... Both myself and craft coach s based in Petaling Jaya, Selangor, however for those based in other states in Malaysia is also welcome to join our watsapp group for more interactive discussion. |

|

|

Dec 21 2019, 03:27 PM Dec 21 2019, 03:27 PM

Return to original view | Post

#68

|

Junior Member

104 posts Joined: Oct 2019 |

& its done!

let me present the making process of a 'side hatchet' @ 'side axe', as its also sometimes known as. whats a side hatchet? > its a tool where an axe head is affixed to the side of a handle, rather than between like this   or through the hole made by the drift   or using the reach around method of lengthening metal to form a connected enclosure to fit the hande like this   what is it used for? mainly this to explain the above - this tool is usually made with a chisel grind. meaning only one side of the cutting edge is sharpened while the other is left full flat. as such, it allows the user to make very clean 'straight' cuts into the wood like the video above anyways, lets get started with the making process of mine... |

|

|

Dec 21 2019, 03:34 PM Dec 21 2019, 03:34 PM

Return to original view | Post

#69

|

Junior Member

104 posts Joined: Oct 2019 |

this is an axe head i made. material is lc steel. after cutting the rough shape, i cold forged the edge.

whats 'cold forged', 'cold forging' or 'cold peening? this and this basically its forging/shaping steel without fire by repeatedly hammering until it thins/flattens out to your desired shape. this method has great merits & i regularly use it. i used the cold forging method to flatten my axe edge to make it broader and better hone it to a thinner point. this results in a reinforced edge thats strong due to the metal being compressed & also lesser overall grinding. if u notice the edge in the pix above - you'll see indentations. these were made using a ball peen hammer, ergo the term 'cold peening'. i next drilled the axe head and attached it a quickly shaped wood handle. again, i used the 'cold peening' method to attach the axe head to the wood handle with 3 steel nails. the either ends of the nails are peened flat. this serves to firmly secure the axe head & handle together. i then proceeded to bevel an edge with a grinder.   this was followed by cutting off the excess wood from the top of the handle.   i next gave the axe a sabre grind to complete the process and peened the edge.   done. i will revisit this down the line to greatly reshape the handle for better ergonomics and fine tune the axe head for better aesthetics. and with that - its done!... a world first - a rarely seen side axe created by using the cold forging & edge peening method. it would have been even more unique if i proceeded with the chisel grind i had originally intended for the axe head - but its nearly impossible to do a chisel grind if you are also going to cold forge an edge. it would be too uneven to be an actual chisel grind due to the imperfections caused by the dented/dimpled metal. as its xmas & new year in the coming & following week - i will be too busy to make any follow up posts for the next 2 weeks or so. will pick up again after that. merry xmas & happy new year to all! hope to see many new crafters emerge in the coming year. i & the postmater will play our part & be a good welcome wagon to any who want to join us This post has been edited by CRAFT_COACH: Dec 21 2019, 05:43 PM |

|

|

Jan 15 2020, 04:06 PM Jan 15 2020, 04:06 PM

Return to original view | Post

#70

|

Junior Member

104 posts Joined: Oct 2019 |

and we're back!

new year, new fun art to look forward to. had a good hol. re-familiarised with some past crafting methods. looking fwd to putting it into practice this year - hopefully with a group of equal minded folks i will restart projects this week. start of with something more novel to set the tone. also will continue & conclude the forgoing methods posts soon too. |

|

|

Jan 15 2020, 04:19 PM Jan 15 2020, 04:19 PM

Return to original view | Post

#71

|

Junior Member

104 posts Joined: Oct 2019 |

QUOTE(vinnyming @ Dec 31 2019, 02:05 PM) I enjoy watching master craftmen in their natural habitat. Those videos gives a sort of satisfying feeling. Not really into forging and smiting, but admire those who have a passion and working at it. thank you!Kudos! same here. its greatly soothing for my 'soul' too. in addition to their natural environment, something about nature & crafting just goes so well too. i rather work in nature than a high tech workshop any day. to me, this is the richest person i know > those who 'get it' - will get what my above statement means. |

|

|

Jan 17 2020, 05:53 PM Jan 17 2020, 05:53 PM

Return to original view | Post

#72

|

Junior Member

104 posts Joined: Oct 2019 |

|

|

|

Jan 17 2020, 06:37 PM Jan 17 2020, 06:37 PM

Return to original view | Post

#73

|

Junior Member

104 posts Joined: Oct 2019 |

this weekend's project is, i guess, gonna be off the beaten path.

previously my projects were very tools/knife making centric this time, i will utilise the same wood/steel working techniques & principles to make something thats more 'accessible' and appealing to general sentiments. in this new year, i would like to demonstrate & have everyone to understand that the same skills required to make wooden or steel tools, can also be put forth towards creating useful everyday products to even niche things like making your own cpu casing, modding remote control or replica models/toys, fabricating/restoring automobile parts, as well as even creating your own outdoor bbq grill, pasta press, etc. you can take the same skills honed from learning crafting & apply it to whatever your desired area is. it does not only have to focus on tools/knife making. the same core concepts can easily be applied to other areas to make what you personally desire. to that end - i will be making a taco press tomorrow! ... hopefully, i will be posting some action shots of it being actually used the day after too. This post has been edited by CRAFT_COACH: Jan 17 2020, 06:37 PM |

|

|

|

|

|

Jan 18 2020, 07:28 PM Jan 18 2020, 07:28 PM

Return to original view | Post

#74

|

Junior Member

104 posts Joined: Oct 2019 |

for whatever reason - i'm having trouble uploading pictures now. will try again later.

|

|

|

Jan 18 2020, 07:41 PM Jan 18 2020, 07:41 PM

Return to original view | Post

#75

|

Junior Member

104 posts Joined: Oct 2019 |

hmmm... been trying more than an hour now - no luck.

guess just gonna have to post tomorrow |

|

|

Jan 19 2020, 08:38 AM Jan 19 2020, 08:38 AM

Return to original view | Post

#76

|

Junior Member

104 posts Joined: Oct 2019 |

finally working, so here we go!

this is a taco press.  its use is pretty self explanatory - u use it to flatten balls of dough. just in case, here's a video of its use now, here's a dui video version of what i wanted to make... or close enough. obviously, i made changes to mine to suit my needs/complement my resources |

|

|

Jan 19 2020, 08:47 AM Jan 19 2020, 08:47 AM

Return to original view | Post

#77

|

Junior Member

104 posts Joined: Oct 2019 |

so without further ado, here, in sequence, is the actual process of what i ended up making

this is the wood that was used. it is treated hardwood re-purposed from a cupboard that was to be discarded. i deconstructed it & salvaged the wood.  this is the wood with pencil markings to show where i was going to cut it to make the 2 base boards  the resulting 2 base boards & other pieces of wood after it is cut with a jigsaw  the 2 baseboards with holed drilled in with a drill & secured together with cable ties    |

|

|

Jan 19 2020, 08:55 AM Jan 19 2020, 08:55 AM

Return to original view | Post

#78

|

Junior Member

104 posts Joined: Oct 2019 |

a shot of all the cut & assembled pieces

this is a salvaged chair leg  a hole has been drilled on top to allow for a bolt to be inserted later  in this piece of cut wood, 2 holes have been made below to allow for screws to be used later  other assorted pieces    salvaged cupboard handle  the pieces assembled together   |

|

|

Jan 19 2020, 09:16 AM Jan 19 2020, 09:16 AM

Return to original view | Post

#79

|

Junior Member

104 posts Joined: Oct 2019 |

a close up of the clamping lever mechanism. pls note how i combined/joined everything

with the addition of a piece of wood that was glued to the frame to act as a pressing wedge and the repurposed handle to allow easy gripping, the taco press is now complete!   glamour shots in good lighting. lol   & done! though no part of this press will actually make contact with dough/raw ingredients - prior to assembly, i nevertheless quick soaked & scrubbed it all down thoroughly with hot water and hyrdrochloric acid, then further spray misted strong vinegar & rubbed it thoroughly into all exposed areas. now that the (enjoyable) hard work's done - am looking forward tomorrow to doing a monday nite mexican feast. i'll be making tacos, fajitas & quesadillas... eventually, i will make naan and chapatis with it, followed by pirogis, ravioli, pita, etc. as cny is drawing near - def will be used to make pau, gyoza & wantan wrappers too. looking forward to seeing perfectly uniform & round flattened pieces of dough in the varied permutations of doughs to come in closing, it was another fun & fulfilling project. hope all reading appreciate that one can do so much more beyond making tools/knives by learning crafting - its all the same base skills. how one chooses to use it/evolve after learning the base skills is up to them. this time i used it for culinary pursuits. next time - maybe modding my own gaming pc casing or fabricating a car gasket... the possibilities are endless with crafting skills. so, if u found this project appealing - go make ur own, folks! dunno how...? come learn This post has been edited by CRAFT_COACH: Jan 19 2020, 09:18 AM |

|

|

Feb 2 2020, 10:12 AM Feb 2 2020, 10:12 AM

Return to original view | Post

#80

|

Junior Member

104 posts Joined: Oct 2019 |

due to maintenance work/upgrade - lowyat acting very screwy.

been like that for nearly 2 weeks. so, i'll only start posting again once this upgrade, etc phase ends... |

| Change to: |  0.0246sec 0.0246sec

1.03 1.03

7 queries 7 queries

GZIP Disabled GZIP Disabled

Time is now: 27th November 2025 - 05:50 AM |