QUOTE(watermineral @ Feb 16 2014, 06:08 AM)

edifier s330, same problem also, constant noise, but the sound more like duuuuuuu....

http://www.youtube.com/watch?v=m2yBSXv0gc0...player_embedded

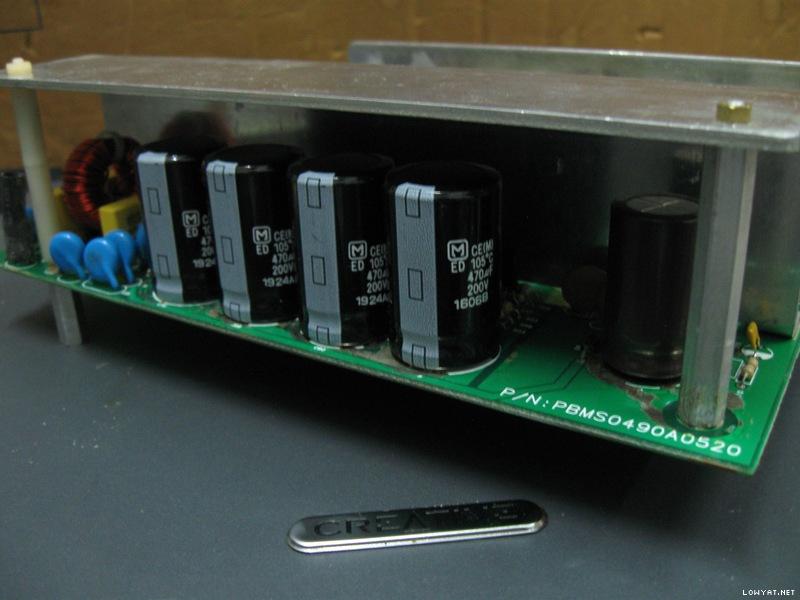

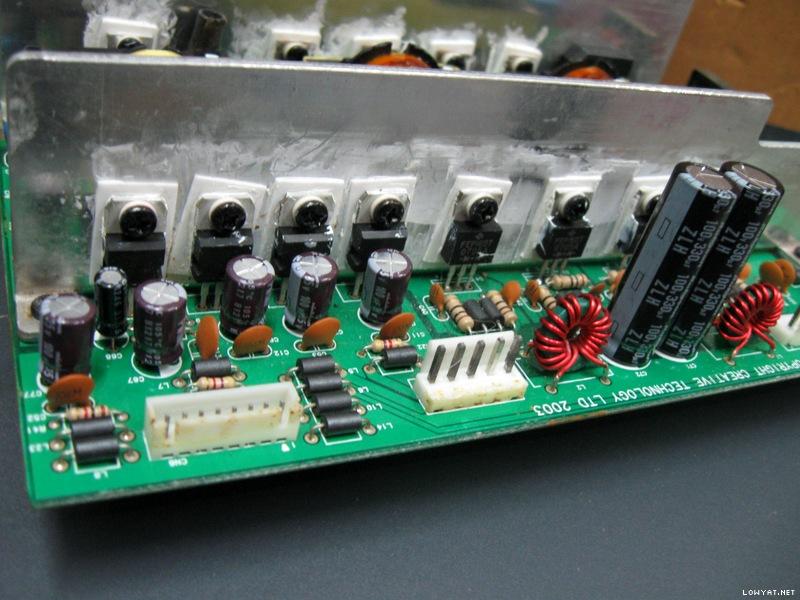

Could be either the power supply section and/or audio power amplifier section. Hard to say until examined closely the internals... http://www.youtube.com/watch?v=m2yBSXv0gc0...player_embedded

QUOTE(chrislue @ Feb 16 2014, 11:14 AM)

I just checked the stock caps I pulled out, found out that almost every copper tubes inside through holes have also been pulled out with caps leads.

Looks like I have to use the "L" way to fix them all.

Can ignore the leads that are connected to the bottom side, just repair the leads that are connected to the top side. Check carefully the location to place the "L" wire on the top as to prevent unwanted connections. Looks like I have to use the "L" way to fix them all.

QUOTE(chrislue @ Feb 16 2014, 11:14 AM)

Is there any good way to avoid this? I tried use solder sucker, didn't work very well, so basically I just melt the solder and then pull out caps by force.

If use that method, then pull them by tilting the capacitor side to side with one lead/leg at a time. The problem is that there is solder between the leads/legs of the capacitor and the tube surface inside that still remained. Usually can be pulled out easily but if the leads/legs are tight inside the hole then the soldering iron had to stay a little longer (to completely melt the solder inside the hole), and that usually can result in the tubes and solder pads coming off due to prolonged heating (as the soldering iron melts the glue than holds them in place). And yeah, desoldering double sided board can sometimes be very difficult as well, especially when there is solder still inside the through hole. The most recommended tool for this type of job is: HAKKO | Desoldering / Rework | HAKKO 808 which is rather pricey but gets the job done. Example of real word usage... » Click to show Spoiler - click again to hide... «

This post has been edited by lex: Feb 16 2014, 01:44 PM

Feb 16 2014, 01:43 PM

Feb 16 2014, 01:43 PM

Quote

Quote

0.0270sec

0.0270sec

0.57

0.57

7 queries

7 queries

GZIP Disabled

GZIP Disabled