Repraps and DIY 3D Printing!, Open source hardware~

|

|

Jan 30 2015, 01:32 PM Jan 30 2015, 01:32 PM

Return to original view | Post

#41

|

Junior Member

292 posts Joined: Jan 2003 |

i do it by agak2, hasn't failed me so far

|

|

|

|

|

|

Feb 2 2015, 02:38 PM Feb 2 2015, 02:38 PM

Return to original view | Post

#42

|

Junior Member

292 posts Joined: Jan 2003 |

abs juice looks abit thick no?

|

|

|

Feb 3 2015, 03:20 PM Feb 3 2015, 03:20 PM

Return to original view | Post

#43

|

Junior Member

292 posts Joined: Jan 2003 |

QUOTE(eehtsitna @ Feb 3 2015, 02:49 PM) Eh? The nozzle is part of the heating block? I thought i read somewhere that its actually separate part. Anyway, thanks for pointing out that it is most likely too much trouble trying to switch the hotend/nozzle around all the time. I might as well get a second printer with a different nozzle size. Nozzle is a separate part, if ur not in a hurry, just order one online. as for housing, search thingiverse or design your own Have been looking high and low for a housing. Will try to look for it again tonight. |

|

|

Feb 4 2015, 09:16 AM Feb 4 2015, 09:16 AM

Return to original view | Post

#44

|

Junior Member

292 posts Joined: Jan 2003 |

http://www.yumeprinter.com/product-category/filament/

I've been seeing these guys post in some fb groups i'm in, not sure about quality but price is def cheap |

|

|

Feb 4 2015, 10:18 AM Feb 4 2015, 10:18 AM

Return to original view | Post

#45

|

Junior Member

292 posts Joined: Jan 2003 |

QUOTE(DarkTenno @ Feb 4 2015, 09:55 AM) converted my mendelmax 1.5 to something diffrent, still need to recalibrate Z and bed leveling my inductive sensor decide to fail on me so have to manually level the bed now I like your workbench, as messy as mine plus last week the green ramps connector melted on me, I always see warning about the connector melting and I see it first hand Also check the transistor that heats the heatbed and see if its overheating, if it is, could be why it cant reach 110, the thermal protection may have kicked in. http://forum.felixprinters.com/viewtopic.php?f=11&t=595 This post has been edited by KLKS: Feb 4 2015, 10:23 AM |

|

|

Feb 4 2015, 12:31 PM Feb 4 2015, 12:31 PM

Return to original view | Post

#46

|

Junior Member

292 posts Joined: Jan 2003 |

ship them with tracking number.

|

|

|

|

|

|

Feb 4 2015, 12:40 PM Feb 4 2015, 12:40 PM

Return to original view | Post

#47

|

Junior Member

292 posts Joined: Jan 2003 |

QUOTE(DarkTenno @ Feb 4 2015, 12:35 PM) problem with those ebay sellers when I asked to ship with tracking they always say it expensive even thought I already said I willing to pay the shipping cost and yet normally they will just ignore my request and end up getting 2 star for my feedback Time to switch to aliexpress |

|

|

Feb 5 2015, 08:19 AM Feb 5 2015, 08:19 AM

Return to original view | Post

#48

|

Junior Member

292 posts Joined: Jan 2003 |

I'm using repetier host with cura/slic3r

|

|

|

Feb 5 2015, 02:01 PM Feb 5 2015, 02:01 PM

Return to original view | Post

#49

|

Junior Member

292 posts Joined: Jan 2003 |

QUOTE(altan @ Feb 4 2015, 10:59 PM) The proper term for G-code generator is slicer. I am using Cura 14 as the slicer and the host software is Octoprint on the Raspberry Pi. Have you dumped the eeprom settings using M503 and comparing it to stock? I know the repetier-firmware has alot of setting that is saved in eepromIMO, easiest slicer and host to use is Cura and Pronterface (now called Printrun for the GUI version). Other known slicers out there: Slic3r (Tons of parameters to play with) and KisSlicer. Other host: Repetier Host and Makerware (works for makerbots only) Firmware is a bit difficult to determine for my printer but as far as I know, it should be a heavily modified Marlin for the Printrboard Rev D. http://reprap.org/wiki/G-code#M503:_Print_settings This post has been edited by KLKS: Feb 5 2015, 02:03 PM |

|

|

Feb 12 2015, 03:47 PM Feb 12 2015, 03:47 PM

Return to original view | Post

#50

|

Junior Member

292 posts Joined: Jan 2003 |

QUOTE(DarkTenno @ Feb 12 2015, 12:35 PM) manage to get my aluminum heatbed to heat up to 100c but it will never pass 105c, I have to bump up my power supply to 14v in order for it to get to 100c if the bed only getting 12v it will never able to reach 100c as claim by 3dprinter.my Did you try measuring how many Amps the bed was pulling vs total amps pushable by the power supply?Did contacting via email but never got any reply calling them always said need to check with technician not sure when but never got any reply ever since, adding no so good review on their product pages obviously wont get approved by them to prove my point I connected the heated bed to a power supply directly and monitor the temp via my IR thermometer with 12v max it can go only to 90c, when I bumped the voltage 14v (equal to supplying more power to it) it able to ge to 105c and stop there heated bed work fine if you printing PLA but if you guys plan to print ABS be aware that those aluminum heated bed sold by 3dprinter.my will not heat up too 100c with 12v power supply I guessing you will need at least 15v or probably 24v to the heated bed |

|

|

Feb 19 2015, 10:51 AM Feb 19 2015, 10:51 AM

Return to original view | Post

#51

|

Junior Member

292 posts Joined: Jan 2003 |

QUOTE(eehtsitna @ Feb 18 2015, 08:12 AM) Howdy guys! Yeah i put oil from time to time, mines starting to rust abit, you could try sourcing stainless steal bearings. the bearings from china are just normal steel ones.Just wondering does everyone lubricate their outer side of their bearing from time to time? Mine seems to be rusting. QUOTE(ishe7ata @ Feb 19 2015, 10:43 AM) My friend did, paid around RM150, it depends on how much the declared value the seller puts.QUOTE(sooyewguan @ Feb 19 2015, 09:01 AM) Happny CNY to all. Ventilation helps Tried to first print ABS with my printer yesterday, the print was ok, but the smell jst horrible compred to P LA. I read that ABS fume is toxic. Does anyone printed with ABS before? How you guys deal with the fume and smell? This post has been edited by KLKS: Feb 19 2015, 10:53 AM |

|

|

Feb 22 2015, 03:15 PM Feb 22 2015, 03:15 PM

Return to original view | Post

#52

|

Junior Member

292 posts Joined: Jan 2003 |

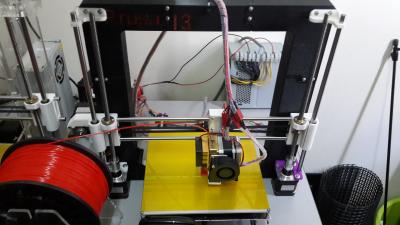

2nd Prusa i3 up and running, this time using ramps 1.4 and 400w PSU. I did abit of power measurements, the hotend pulled about 3 amps and the heatbed about 7.

Also noticed that the PSU couldnt regulate the 12v properly, after a while it dipped to about 11.5. Must be one of em cheap PSU's

Made a custom holder for the ramps,fan and mosfet heatsink, moved the mosfets onto a heatsink.

This post has been edited by KLKS: Feb 22 2015, 03:19 PM |

|

|

Feb 22 2015, 03:43 PM Feb 22 2015, 03:43 PM

Return to original view | Post

#53

|

Junior Member

292 posts Joined: Jan 2003 |

QUOTE(ishe7ata @ Feb 22 2015, 03:36 PM) Hey man, My first i3 was a kit (from aliexpress), 2nd i3 (the one pictured above) is assembled from parts, 90% of which is from aliexpress. Things which i bought locally were the smooth rods, afew bearings, and screws and bolts.Where did you buy the kit?? Or did you assemble things yourself? I plan on buying a kit I want to get most of things locally. |

|

|

|

|

|

Feb 22 2015, 09:12 PM Feb 22 2015, 09:12 PM

Return to original view | Post

#54

|

Junior Member

292 posts Joined: Jan 2003 |

This is the store i bought from on aliexpress

http://www.aliexpress.com/store/319147 Paid about 440USD shipped incl 2 rolls of fillament, was lucky didn't kena tax. This post has been edited by KLKS: Feb 22 2015, 09:16 PM |

|

|

Feb 22 2015, 09:19 PM Feb 22 2015, 09:19 PM

Return to original view | Post

#55

|

Junior Member

292 posts Joined: Jan 2003 |

I just chanced upon this while browsing aliexpress, looks pretty good

http://www.aliexpress.com/store/product/Ho...2026704108.html |

|

|

Feb 23 2015, 10:58 AM Feb 23 2015, 10:58 AM

Return to original view | Post

#56

|

Junior Member

292 posts Joined: Jan 2003 |

Have you tried printing at 190-195, i've had to up the temp of some PLA prints to 210 just so there's layer adhesion. Sometimes it can be a clogged nozzle because of poor quality fillament. Maybe post some pictures?

|

|

|

Feb 23 2015, 01:08 PM Feb 23 2015, 01:08 PM

Return to original view | Post

#57

|

Junior Member

292 posts Joined: Jan 2003 |

QUOTE(DarkTenno @ Feb 23 2015, 01:05 PM) I was not planning to print ABS at all actually, Just heating the hotend to get it melt my PLA Isnt that where the grub screws go in? If the grubscrew fits snugly, there shouldnt be any leakage.I'll sent you PM [attachmentid=4349139] |

|

|

Feb 25 2015, 11:02 AM Feb 25 2015, 11:02 AM

Return to original view | Post

#58

|

Junior Member

292 posts Joined: Jan 2003 |

If its not broken, don't break it

|

|

|

Feb 25 2015, 11:41 AM Feb 25 2015, 11:41 AM

Return to original view | Post

#59

|

Junior Member

292 posts Joined: Jan 2003 |

If you are using repetier host, u can do that from within the software, doesn't require messing with the firmware.

|

|

|

Mar 2 2015, 11:02 AM Mar 2 2015, 11:02 AM

Return to original view | Post

#60

|

Junior Member

292 posts Joined: Jan 2003 |

QUOTE(eehtsitna @ Mar 2 2015, 10:58 AM) Sounds like a similar issue with mine and i have yet to figure out a solution for that. I tried swapping a new RAMPS and yet the mosfet in the new RAMPS seems to be over heating too. If your comfortable with a soldering iron, you could move the mosfets over to a heatsink block and put a fan over it. That's what i did (see the pic afew posts ago)That aside, does any one have a good spool holder which you would recommend? Printed out one over the weekend but it does not function that well. |

| Change to: |  0.0238sec 0.0238sec

0.42 0.42

7 queries 7 queries

GZIP Disabled GZIP Disabled

Time is now: 11th December 2025 - 12:56 AM |

All Rights Reserved © 2002- 2025 Vijandren Ramadass (~unite against racism~)

Powered by Invision Power Board © 2025 IPS, Inc.

Quote

Quote