40 hour print failed because my 1 year + PLA printed Z-Axiz coupler decided to fail on me.

Drillz of the prehistoric human child skull a client ask me to print... A real waste.

Repraps and DIY 3D Printing!, Open source hardware~

|

|

Jan 4 2016, 08:09 PM Jan 4 2016, 08:09 PM

Return to original view | Post

#241

|

Junior Member

188 posts Joined: Sep 2009 From: Either PJ, JB or SG but not at your house! |

|

|

|

|

|

|

Jan 6 2016, 06:26 PM Jan 6 2016, 06:26 PM

Return to original view | Post

#242

|

Junior Member

188 posts Joined: Sep 2009 From: Either PJ, JB or SG but not at your house! |

QUOTE(teohes @ Jan 6 2016, 05:38 PM) Is there a supplier for Xtc-3D locally ? I met a guy selling that epoxy coating set for RM 90 during Comic Fiesta. I will send you his contact via PM if I can find his business card.http://www.smooth-on.com/Epoxy-Coatings-XT...1429/index.html |

|

|

Jan 12 2016, 11:46 AM Jan 12 2016, 11:46 AM

Return to original view | Post

#243

|

Junior Member

188 posts Joined: Sep 2009 From: Either PJ, JB or SG but not at your house! |

QUOTE(hihi @ Jan 11 2016, 10:20 AM) Made a brass connector to fix the rod to the frame. Got pic of the brass connector? If it was my case, I would 3D print a smooth rod holder instead Having another problem yesterday, my lcd no display after connect to power supply, used few hours to figure out, need to update the firmware to make it work. OK, so the LCD is working now? BTW, very nice steel frame, I would have painted it... The frame did not come warped? This post has been edited by altan: Jan 12 2016, 11:47 AM |

|

|

Jan 19 2016, 08:35 PM Jan 19 2016, 08:35 PM

Return to original view | Post

#244

|

Junior Member

188 posts Joined: Sep 2009 From: Either PJ, JB or SG but not at your house! |

Hey everyone, I am stocking and selling spare parts for RepRap printers.

You can check it out at [WTS] 3D Printer & Reprap Parts / Accessories / Spare / Replacement Parts. Anyone interested can PM me and COD available around PJ area. This post has been edited by altan: Jan 19 2016, 11:46 PM Attached thumbnail(s)

|

|

|

Jan 24 2016, 01:54 AM Jan 24 2016, 01:54 AM

Return to original view | Post

#245

|

Junior Member

188 posts Joined: Sep 2009 From: Either PJ, JB or SG but not at your house! |

|

|

|

Jan 26 2016, 12:09 PM Jan 26 2016, 12:09 PM

Return to original view | Post

#246

|

Junior Member

188 posts Joined: Sep 2009 From: Either PJ, JB or SG but not at your house! |

QUOTE(hihi @ Jan 26 2016, 10:23 AM) Having a hard time to level my printing bed. I level after put a 3mm glass. After 4 side leveled. Moved the noozle to center, and the noozle was touching the bed. Should put a picture of your print bed so we get a better idea of your setup.How should i overcome this problem? Did you clamp down the glass sheet with binder clips? Is it a heated print bed and was the heater running? When you level the 4 corners , was the nozzle touching the bed without gap or small gap? This post has been edited by altan: Jan 26 2016, 12:49 PM |

|

|

|

|

|

Jan 28 2016, 12:11 PM Jan 28 2016, 12:11 PM

Return to original view | Post

#247

|

Junior Member

188 posts Joined: Sep 2009 From: Either PJ, JB or SG but not at your house! |

QUOTE(hihi @ Jan 28 2016, 11:57 AM) Manage to level the bed, did it after heat up the bed. Not perfectly but at least usable now. The different between side and center about 0.1mm different. Alright, that is good. Since the difference is about 0.1mm I have a suggestion, you can set your first layer thickness to at least 0.2mm or more depending on nozzle size. By doing that there will be some squishing but that is fine as long as the first layer sticks to the bed. If the centre drops in/curve inwards, then need to relevel the Nozzle into the bed corners by 0.1mm to prevent lifting in the centre.Isolated the lower part of heat bed but unable to achieve110c for long time. Checked to voltage during heating only 10.5v. The bed resistant 1.7ohm. Tonite will try print abs using 105c. |

|

|

Feb 5 2016, 04:52 PM Feb 5 2016, 04:52 PM

Return to original view | Post

#248

|

Junior Member

188 posts Joined: Sep 2009 From: Either PJ, JB or SG but not at your house! |

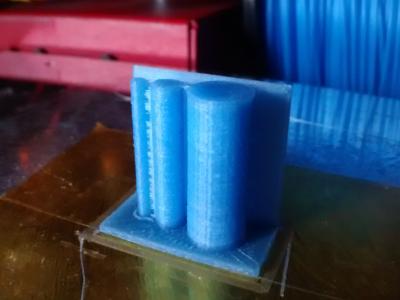

QUOTE(feiming @ Feb 5 2016, 03:41 PM) i have this problem. I tried to change the glass to 6mm. I suspect it's the binder clip pressing too hard. Did you mean G clamps? Other solution is to 3D print ABS clips that will give just the right pressure.I'm thinking to change to small clamp. That way i can control the clamping force. Finally my setup for ABS is a success but the prints are delaminating when bent along the layers for thin structures. I wasn't expecting 3D printed ABS to be inferior to PLA. Drillz included.

|

|

|

Feb 13 2016, 02:42 AM Feb 13 2016, 02:42 AM

Return to original view | Post

#249

|

Junior Member

188 posts Joined: Sep 2009 From: Either PJ, JB or SG but not at your house! |

QUOTE(huiko12 @ Feb 13 2016, 02:03 AM) The most budge friendly RepRap is still the Prusa i3. There are not many RepRap variants sold in Malaysia other than the Mendel, Rostock/kossel, and Prusa. On the other hand, if you have the budget for anything more than 2.5k then I would recommend getting a consumer 3D printer that's fully assemble (if you are not the adventurous type). Just note that a lot of these desktop 3D printer vary in price and the price absolutely does not guarantee reliablility. Even an expensive Makerbot can get jams and print issues compared to cheaper clones like the Flashforge for the same specs.My advice is to read up about 3D printers first or ask about other people experience before deciding on getting a 3D printer. If you just want to print a few things, then I would recommend using a 3D printing service as seen in my signature below. This post has been edited by altan: Feb 13 2016, 02:44 AM |

|

|

Feb 14 2016, 12:02 PM Feb 14 2016, 12:02 PM

Return to original view | Post

#250

|

Junior Member

188 posts Joined: Sep 2009 From: Either PJ, JB or SG but not at your house! |

QUOTE(huiko12 @ Feb 14 2016, 02:49 AM) A RepRap can achieve consumer grade prints by sourcing quality hardware (linear rods, lead screws, frame, electronics, design, etc) and optimising the settings for the electronics and firmware. In other words, RepRap aren't consumer grade printers unless you intentionally put in the time, money, and effort to redesign and build a consumer grade RepRap printer. RepRap gives you the basic framework to barely print something but a lot of development is needed to make it a great 3D printer. I always have second thought about buying a kit from any seller because theses kits may have parts that aren't up to standard. Also, hihi recently built a Prusa i3 steel and he might be able to share some insights on his printer. If he is still active. |

|

|

Feb 14 2016, 02:47 PM Feb 14 2016, 02:47 PM

Return to original view | Post

#251

|

Junior Member

188 posts Joined: Sep 2009 From: Either PJ, JB or SG but not at your house! |

QUOTE(huiko12 @ Feb 14 2016, 02:33 PM) where can i order all the stuff except for the main body ... they use Full acrylic frame i was thinking to make mine full metal frame Refer to page 72 in this topic for the steel frames. https://forum.lowyat.net/topic/2249129/+1420Sourcing for the chrome plated linear bearings locally is expensive, so I suggest try taobao or eBay. Same for electronics as well. You can get the hotend set from me. See my sig below. |

|

|

Feb 16 2016, 01:00 PM Feb 16 2016, 01:00 PM

Return to original view | Post

#252

|

Junior Member

188 posts Joined: Sep 2009 From: Either PJ, JB or SG but not at your house! |

QUOTE(SupermotoXL @ Feb 16 2016, 10:30 AM) Wow nice. |

|

|

Feb 18 2016, 01:50 AM Feb 18 2016, 01:50 AM

Return to original view | Post

#253

|

Junior Member

188 posts Joined: Sep 2009 From: Either PJ, JB or SG but not at your house! |

QUOTE(Drian @ Feb 18 2016, 01:17 AM) I was thinking of changing the plastic parts on the frame in my prusa i3 to pure aluminium. X-axis motor mount plastic holding the LM8UU broke. No big deal , can just print another one but I thought perhaps changing it to all aluminum would look better. How did the x-axis motor mount break? Was the plastic part printed with ABS or PLA?Has anyone done it before or know if any company sells it? Aluminium would be expensive and probably some machine shops may not make it for you considering the design of the part. I don't think any company would stock Prusa i3 printable parts in aluminum. |

|

|

|

|

|

Feb 18 2016, 02:41 PM Feb 18 2016, 02:41 PM

Return to original view | Post

#254

|

Junior Member

188 posts Joined: Sep 2009 From: Either PJ, JB or SG but not at your house! |

QUOTE(Drian @ Feb 18 2016, 02:01 PM) I guess there were many times the z axis limit switch wasnt aligned properly so when the print head crash the bed causing stress on the plastic part holding the lm8uu. I also really hate it when the hotend crashes into the build plate. I think better if the part breaks or else if it keeps going without stopping, the aluminum couplers will deform from continuous stretching.QUOTE(eehtsitna @ Feb 18 2016, 02:32 PM) Thread activity died down a while a go. Now picking up speed I think. Me currently busy fulfilling 3D printing orders from clients. A little overloaded right now and its almost time for me to buy a second 3D printer. |

|

|

Feb 18 2016, 10:20 PM Feb 18 2016, 10:20 PM

Return to original view | Post

#255

|

Junior Member

188 posts Joined: Sep 2009 From: Either PJ, JB or SG but not at your house! |

QUOTE(izzudinhafiz @ Feb 18 2016, 06:44 PM) Nice to hear business is good for you! Thanks but for that to happen, I will need to invest in setting up a metal fab workshop and also do a proper survey on the number of 3D printer owners in Malaysia. I can keep supplies but if no one wants to buy them then I have a lot more than I can use for maintaining my current printer. |

|

|

Feb 22 2016, 12:31 PM Feb 22 2016, 12:31 PM

Return to original view | Post

#256

|

Junior Member

188 posts Joined: Sep 2009 From: Either PJ, JB or SG but not at your house! |

QUOTE(Drian @ Feb 22 2016, 11:26 AM) Anyone here has done a core xy 3d printer build? Nope but I have seen someone made a small 3D printer with that design. Why don't you buy a new set of linear rods and bearings instead of dismantling the Prusa i3. You can sell the assembled Prusa i3 to someone who wants to get into RepRap quickly.Thinking of taking apart my prusa i3 to build one using aluminium extrusion. Also, you might need to purchase really long GT2 timing belt since the corexy design utilizes long belt lengths. The belt follows along the 3 sides of the printer frame and loops on towards the centre so, the length depends on the perimeter of the printer size. |

|

|

Feb 22 2016, 06:01 PM Feb 22 2016, 06:01 PM

Return to original view | Post

#257

|

Junior Member

188 posts Joined: Sep 2009 From: Either PJ, JB or SG but not at your house! |

QUOTE(izzudinhafiz @ Feb 22 2016, 05:19 PM) u can get free length GT2 belts on ebay for quite a bargain. although the shipping time for eBay is always unpredictable. If im not mistaken, blomker sells GT2 belts by the meter as well. quite reasonably priced aswell Good to know there a shop selling linear rails in KL for a reasonable price, provided if you want to spend that kind of money. on a side note, why dont upgrade to Hiwin linear rails instead of linear rods and linear bearings? They're much better at resisting twisting motion. i've used them for a different project. a shop at Loke Yew sells them for like RM 100 for a 45cm long ones if i recall correctly Nowadays you can get stuff delivered from ebay within 2 - 4 weeks even for economy shipping. Obviously there is still that randomness factor but my last batch of shipping all came within 2 weeks. By the way, I have a 10 meter roll of GT2 timing belt. |

|

|

Feb 22 2016, 07:29 PM Feb 22 2016, 07:29 PM

Return to original view | Post

#258

|

Junior Member

188 posts Joined: Sep 2009 From: Either PJ, JB or SG but not at your house! |

QUOTE(Drian @ Feb 22 2016, 07:06 PM) there's probably 700-800 ringgit worth of salvageable parts there , 4 8mm rod, 2 100mm rods, electronics, 8 lm8uu, 5 stepper motors, heat plate, bearing. PMed you for your Prusa i3. Unless I can sell it at that price. Also, the rails are considered better than the linear rods since, they are usually made with hardened steel (very hard to bend and never flexes). I worked with one reprap printer using these rails and they are way better than linear rods and bearings since you only need one rail each to support a build platform or extruder in the 2 horizontal axis. You can use 2 rails for the z-axis, placed on two ends of one side of the printer against the wall. |

|

|

Feb 25 2016, 09:57 AM Feb 25 2016, 09:57 AM

Return to original view | Post

#259

|

Junior Member

188 posts Joined: Sep 2009 From: Either PJ, JB or SG but not at your house! |

QUOTE(hihi @ Feb 25 2016, 09:50 AM) Do you guys using fan to cool down during your printing? I'm using abs and always having problem for the edge especially smaller object. ABS is very difficult to print for first time users. PLA is an easy alternative but trade off between s the material property.Print a 2 in 1 fan duct, it's help but sometimes will have crack problem. For ABS printing, never use an external cooling fan at all even during bridging. The cooling fan causes severe warping and causes uneven temperature around the print. This will lead to uneven heights and even cracks. I find that printing ABS requires no air flow and steady environment temperature. |

|

|

Mar 1 2016, 10:53 AM Mar 1 2016, 10:53 AM

Return to original view | Post

#260

|

Junior Member

188 posts Joined: Sep 2009 From: Either PJ, JB or SG but not at your house! |

|

| Change to: |  0.0642sec 0.0642sec

0.60 0.60

7 queries 7 queries

GZIP Disabled GZIP Disabled

Time is now: 14th December 2025 - 08:21 PM |