Lapping Guide -By lolhalol

Ok here we go. Lapping, lapping, lapping, I know you would have heard about lapping from somewhere and wondered what it was. Well lapping is processes of sanding something to make it more flat. In our case, the bases of our heat sinks (or processors) to have improved contact with the processor or vice versa to further improve the thermal transfer between the heat sink and the processor or vice versa. The more contact both have, the better cooling is achieved. Nothing is flat, and lapping is one of the solutions we have to achieve better results. However, lapping doesn't fully make everything better. That's where thermal compounds come into play. They will fill in the microscopic valleys of the two metals. By lapping you are

reducing the size of the microscopic valleys thus making the thermal compound and metals work more efficiently. Lapping works and every heat sink you lap will give you experience to know just how flat those heat sinks really are.

Ok here is what you need:-

1) 800Grit Sandpaper, you can use any brand.

2) 1500Grit sandpaper, you can use any brand.

3) A piece of glass or mirror ( make sure its big enough for your sandpaper )

4) A rag/old cloth or a tack cloth

5) Arctic Silver 5

6) A glass of water

7) A roll of masking tape or any kind of tape

8) And obviously your heat sink or whatever you want to lap, in my case my Swiftech Storm G4 Rev.2.

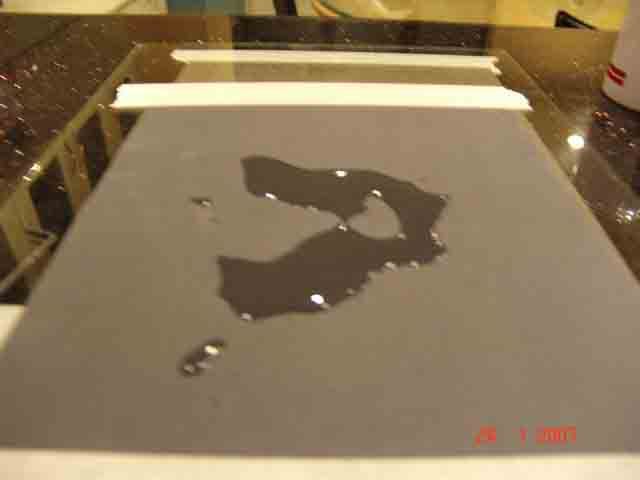

This was the Storm before it was lapped.

As you can see it was already pretty flat to begin with, look at the TIM spread out so well. I know, many of you guys will be like, don't lap a Swiftech block, you will only, make it worse. Well to tell u the truth, when I got it, and after I lapped it, I had a 1 degree drop, so I don't really care what you say. Of course you might have a different result. Ok enough bickering, let's move on.

Step 1: Take your piece of glass and lay it on some old newspapers or a magazine so that its lifted off the table or your workbench, this is so that you can easily move the glass or flip it over later.

Step 2: Take the 800grit sandpaper and lay it out on the glass. Then tape it onto the glass using the roll of masking tape.

Step 3: Take your 1500grit sandpaper and lay it out onto the other side of the glass using the same way as step 2.

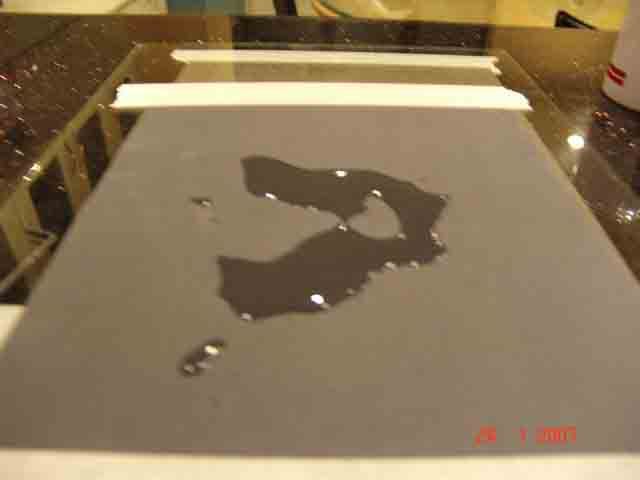

Step 4: Pour a small amount of water onto the 800grit sandpaper side of the glass.

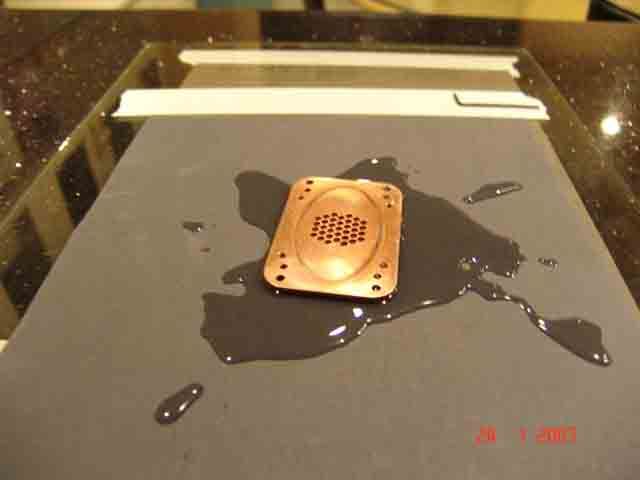

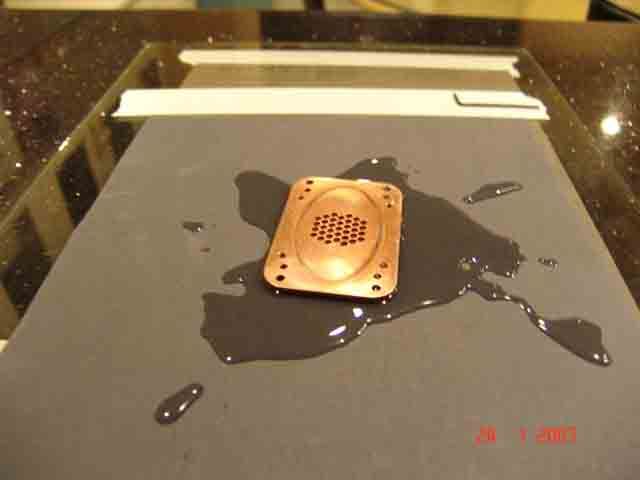

Step 5: Disassemble your heat sink, all fans, led's, anything that can be removed please do so now. In my case, I remove four bolts to get the cooper base out.

Step 6: Put your heat sink into the water that's on your sandpaper.

Step 7: Grab hold of your heat sink/block and with even pressure, move it around in any way that is easier for you, figure 8, up-down, left-right, all is ok, and you can even mix the movement. You would know when to stop when you don't feel resistance (resistance from both directions left-right, up-down). Use your own judgment for this. The following picture is after 800grit.

This post has been edited by lolhalol: Jan 26 2007, 06:21 PM

This post has been edited by lolhalol: Jan 26 2007, 06:21 PM

Jan 19 2007, 02:33 PM

Jan 19 2007, 02:33 PM

Quote

Quote

0.0224sec

0.0224sec

0.44

0.44

6 queries

6 queries

GZIP Disabled

GZIP Disabled