~AIR COOLING DISCUSSION THREAD~

Didnt know that there was a thread like this before created by

sHawTY. Here are the links back to there:

V1V2 INTRODUCTIONHi Lyn forummer, this is the first time i ever created such thread. I hope u guys will give a feedback to me if there is any noobness of mine via PM. First and foremost, this thread is created to gather temperature results from users of various CPU cooler for the reference of other forummers. Intel and AMD stock coolers are welcomed too

Other than that, there will also be a brief explanation of factors that affects temperature and some basic understanding of temperature reading softwares taken from the guide by our Lowyat.net Elite member mr.

kmarc. The thread will be updated from time to time by me, so hope u guys can come in with all the results and screenshots. The coolers results will be updated starting from POST#2 and will be listed in Alphabetical order for ease of search except for

STOCK COOLERS from Intel and AMD which will be at the very top

To post ur result, all u guys need to do is just include all these information in such way:

» Click to show Spoiler - click again to hide... «

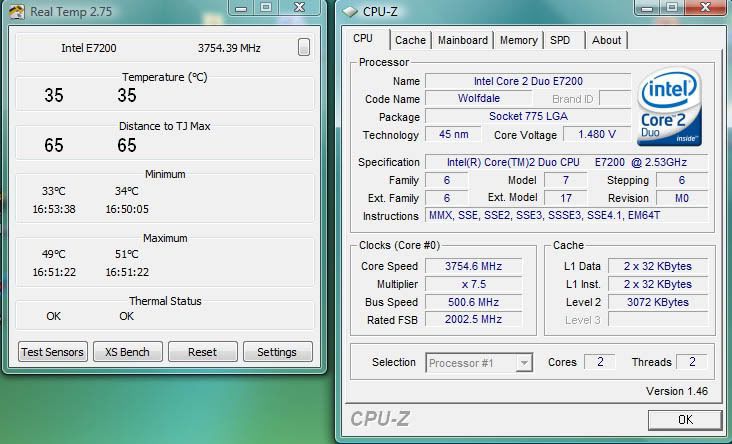

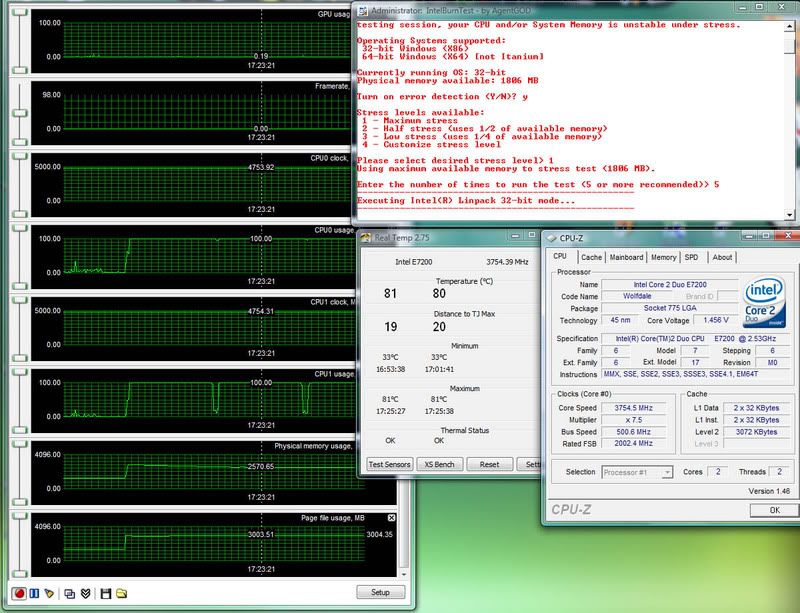

Nickname/heatsink used/thermal paste used/processor model(must include % overclock)/vcore used in bios setting/fan used/idle temps/load temps/ambient/stressing sofwareother than that, pls include together with a screenshot in ATTACHMENT as well with clock speed shown on cpu-z and temperature reading on load using temperature softwares such as coretemp, realtemp, speed fan ETC...

before posting a result, pls make sure u have already stressed the processor for at least 20 minutes first

EXAMPLE:

EXAMPLE: » Click to show Spoiler - click again to hide... «

tkh_1001/ Xigmatek S1283 Red Scorpion/ Tuniq Tx2/ Intel C2Q Q9450 @ 3.44ghz(29% overclock)/ 1.35v/ stock fan/ 42c/ 60c/ aircond

OR non-aircond/ prime95

after posting the results, pls PM me with a link to ur post n i will update the information according to ur cpu cooler

TIPS & GUIDESAlright, since this is an air cooling DISCUSSION thread, i would like to include some tips n guide which i found from MR.

AH GOO to help those who are still new. Most of the guides n tips provided are just basically a kopi n pasta

Pls notify me if the tips are outdated already as i am still new to PC cooling actually

GENERAL UNDERSTANDING OF CPU TEMPERATURE AND TEMPERATURE MONITORING SOFTWARE

GENERAL UNDERSTANDING OF CPU TEMPERATURE AND TEMPERATURE MONITORING SOFTWAREFor all the newbies, pls read this link first as it will help u guys understand better the technical jargons used n what temperature monitoring software indication means. Other than that, there are also general guide on how to reduce ur cpu temperature

Pls click here ---------->

http://forum.lowyat.net/topic/666785GOOD HEATSINK CHARACTERISTICS» Click to show Spoiler - click again to hide... «

HIGH HEATSINK SURFACE AREAIt's at the surface of the heatsink where the thermal transfer takes place. Therefore, heatsinks should be designed to have a large surface area; this goal can be reached by using a large amount of fine fins, or by increasing the size of the heatsink itself.

GOOD AERODYNAMICSHeatsinks must be designed in a way that air can easily and quickly float through the cooler, and reach all cooling fins. Especially heatsinks having a very large amount of fine fins, with small distances between the fins may not allow good air flow. A compromise between high surface (many fins with small gaps between them) and good aerodynamics must be found. This also depends on the fan the heatsink is used with: A powerful fan can force air even through a heatsink with lots of fine fins with only small gaps for air flow - whereas on a passive heatsink, there should be fewer cooling fins with more space between them. Therefore, simply adding a fan to a large heatsink designed for fanless usage doesn't necessarily result in a good cooler.

GOOD THERMAL TRANSFER WITHIN THE HEATSINKLarge cooling fins are pointless if the heat can't reach them, so the heatsink must be designed to allow good thermal transfer from the heat source to the fins. Thicker fins have better thermal conductivity; so again, a compromise between high surface (many thin fins) and good thermal transfer (thicker fins) must be found. Of course, the material used has a major influence on thermal transfer within the heatsink. Sometimes, heat pipes are used to lead the heat from the heat source to the parts of the fins that are further away from the heat source.

PERFECT FLATNESS OF THE CONTACT AREAThe part of the heatsink that is in contact with the heat source must be perfectly flat. A flat contact area allows you to use a thinner layer of thermal compound, which will reduce the thermal resistance between heatsink and heat source. But most of the heatsink contact surface are not perfectly flat. So, some users will lap their heatsinks in order to get better flatness. Read

Lowyat.net Lapping Thread for more detailed explanation

GOOD MOUNTING METHOD

GOOD MOUNTING METHODFor good thermal transfer, the pressure between heatsink and heat source must be high. Heatsink clips must be designed to provide a strong pressure, while still being reasonably easy to install. Heatsink mountings with screws/springs are often better than regular clips. Thermoconductive glue or sticky tape should only be used in situations where mounting with clips or screws isn't possible.

HEATSINK SURFACE TREATMENTAluminum heatsinks are usually anodized; a choice of many colors is available. One might think that black is good, because it is best for heat emission by radiation. This is wrong. Heatsinks get rid of heat by convection (that is, heat is transferred to the air molecules travelling along the heatsink surface - if a fan is involved, we call it "forced convection"). For convection, the color does not matter at all.

Copper heatsinks are sometimes plated with silver or even gold (seriously - Zalman produced such a heatsink, model CNPS3000GOLD). This is supposed to prevent corrosion and improve thermal characteristics. But actually, the plating is too thin to have any effect on thermal conductivity. It is true that the surface of a copper heatsink may slightly corrode; but since they are operating in a dry environment, and do not have to withstand extreme temperatures, corrosion is not really a problem. During the lifetime of a PC heatsink, the corrosion layer will not get thick enough to have any negative effect on cooling.

So, do not worry about the surface treatment of your heatsinks, and do not spend extra for some special surface treatment (such as silver plating). Technically, there is no justification for it.

MEASURING HEATSINK PERFORMANCE/ THERMAL RESISTANCE θ» Click to show Spoiler - click again to hide... «

Heatsink performance is measured in °C/W (or K/W - since we're dealing with temperature differences, there is no difference between Celsius and Kelvin scale here). We refer to this as thermal resistance (θ).

An example for what these values mean: if a thermal load of 20W is applied to a heatsink, and this causes the temperature of the heat source to raise by 10°C, the heatsink has a rating of of 10°C/20W = 0.5°C/W.

0.5°C/W means that for every 1 watt of thermal load, there will be increase of 0.5°C in temperature.

A θ value is valid only for a certain power load and a certain temperature range.

The thermal resistance of standard coolers for PC CPUs is usually not specified by the heatsink manufacturers, and if it is, it's often inaccurate or intentionally skewed for marketing purposes. You cannot judge heatsink performance by comparing θ specifications from different manufacturers.

The θ values specified by manufacturers specialized in heatsinks for industrial applications (especially large passive heatsinks) are usually more accurate, though.

HEATSINK MATERIAL» Click to show Spoiler - click again to hide... «

The thermal conductivity of the heatsink's material has a major impact on cooling performance. Thermal conductivity is measured in W/mK; higher values mean better conductivity.

As a rule of thumb, materials with a high electrical conductivity also have a high thermal conductivity. Basically, Alloys have lower thermal conductivity than pure metals, but may have better mechanical or chemical (corrosion) properties.

The following materials are commonly used for heatsinks:

ALUMINIUM

It has a thermal conductivity of 205W/mK, which is good (as a comparison: steel has about 50W/mK). The production of aluminum heatsinks is inexpensive; they can be made using extrusion. Due to its softness, aluminum can also be milled quickly; die-casting and even cold forging are also possible. Aluminum is also very light (thus, an aluminum heatsink will put less stress on its mounting when the unit is moved around).

COPPER

It's thermal conductivity is about twice as high as aluminum - almost 400W/mK. This makes it an excellent material for heatsinks; but its disadvantages include high weight, high price, and less choice as far as production methods are concerned. Copper heatsinks can be milled, die-cast, or made of copper plates bonded together; extrusion is not possible.

SILVER

It has an even higher thermal conductivity than copper, but only by about 10%. This does not justify the much higher price for heatsink production - however, pulverized silver is a common ingredient in high-end thermal compounds.

HEATPIPES» Click to show Spoiler - click again to hide... «

Basically, heatpipe is a closed metal tube in vertical orientation, filled with a small amount of water, and a heatsink mounted on its upper side. If you apply a heat source to the lower side, the water will evaporate, while cooling the heat source. The vapor will move up, and condense near the heatsink on top. From there, water will drip back to to the bottom, evaporate again, etc.

At normal atmospheric pressure, this would allow the heat pipe to keep the heat source at a temperature of around 100 degress Celsius, the temperature at which water evaporates. However, since heat pipes are tightly sealed tubes, the exact evaporation temperature can be further adjusted to a certain extent by varying the pressure inside the tube (usually reducing it). To cover other temperature ranges, heat pipe manufacturers use various working fluids instead of water, to cover a very wide range of temperatures.

One problem stays: A heat pipe designed for a certain temperature range will only work well in this range; designing a universal heat pipe for all temperature ranges is not possible. Apart from the vapour temperature range, factors like thermal stability and thermal conductivity influence the choice of working fluid.

It is quite obvious that this design will only work in vertical orientation. To overcome this limitation, commercially available heat pipes do not rely on gravity alone to move the liquid back to the heat source; they take advantage of capillary action. The inside of the heat pipe tube is filled with a capillary structure, often referred to as wick. Not only the wick itself influences the strength of the capillary action, but also the choice of working fluid. A high surface tension of the working fluid improves performance.

THERMAL PASTE (A.K.A TIM)» Click to show Spoiler - click again to hide... «

WHY NEED THERMAL PASTE?The surface of a CPU or a heatsink is never entirely flat. If you place a heatsink directly on a CPU, there will be tiny (invisible) gaps between the two. Since air conducts heat poorly, these gaps have a very negative effect on the heat transfer. Therefore, an interface material with a high thermal conductivity is needed to fill these gaps, and thus improve heat conductivity between CPU and heatsink. Most standard thermal compound consists of silicone. However, silicone doesn't have a high thermal conductivity, so they also contains zinc oxide to improve this. The zinc oxide also explains its white colour. High-End thermal compounds are usually silicone-free, and use metal-based additives (e.g. aluminum oxide or nitride, or even pulverized silver!) instead of Zinc Oxide. To look for the best thermal paste around, look at this:

33 Way TIM ComparisonHOW SHOULD I APPLY TIM?Generally, the thinner the layer, the better. But make sure that the entire contact area between CPU and heatsink is covered; otherwise hot-spots can form. Then, make sure the contact of the heatsink and the CPU is tight enough. Compression will often times reduce the amount of thermal compound needed between the cooler and processor, and allow a larger metal to metal contact area which is more efficient than having fluid weaken the thermal conductance. Following are some

MUST READ links for ways to apply thermal paste on different type of heatsink base:

-Round base coolers-Square base coolers-HDT coolersHOW TO CLEAN THE TIM?I heard a lot of forummers here especially those old timer ones telling me that they only use normal tissue papers to wipe away those thermal paste. But normally what I do is cleaning it by using thermal paste remover like

ArctiClean because its easier to remove the sticky thermal paste and I can be sure that I will have a really clean surface for the new paste. There is nothing wrong if you dont use it, its just a personal preference actually

FANS» Click to show Spoiler - click again to hide... «

FAN PERFORMANCEPerformance of fans is typically measured by air volume per time (usually in cubic feet per minute, CFM), or by air speed. CFM values are more meaningful than air speed measurements, since they take into account the size of the fan. Obviously, a 120x120mm fan will provide better cooling than a 50x50mm fan, even if both produce the same air speed. Given CFM specifications are valid only when the pressure on both sides of the fan is equal; that is, when the fan is operating in free space. Under real-life conditions, when the fan is installed in a device, the specified CFM rating of the fan will not be reached; here, it depends on installation and on the overall design of the cooling system. Other than that, fans also have noise rated in dB. Below is a simple chart of noise level:

0 to 20 dB -- Very faint

20 to 40 dB -- Faint

40 to 60 dB -- Moderate

60 to 80 dB -- Loud

80 to 100 dB -- Very loud

100 to 140 dB -- DeafeningBEARING TYPESBasically, there are a few types of fan bearings used. Each of them have different life expectancy and may produce lower noise. Below are the brief explanation on certain types of fan bearing and its features:

SLEEVE BEARINGSleeve bearing is a kind of bearing containing oil or lubricant within a friction contact when fan is rotating. The friction contact between sleeve bearing and the shaft is a face friction. The face friction will create higher noise levels and temperature. The higher the temperature caused by the friction, the greater the possibility for oil leakage due to evaporation. This causes the contact of the bearing to become rough and dry when the oil leaks after a certain period time. Furthermore, the uneven contact usually results in high temperature, abnormal noise and this can cause a malfunction on the fan. The lifespan of sleeve bearing fan is approximately 20K to 30K hours or 1/2 of the lifespan of ball bearing fans. In case you guys wanted to replenish the oil inside the bearing, please refer to this

GUIDE by our own lowyat.net member

ff7ytaBALL BEARINGFor ball bearing fans, there are several miniature steel balls surrounding the cylinder. When the fan rotates, the balls rotate too. Compared to sleeve bearing, it is point friction and has less friction. There are less oil evaporation problems so its lifespan is longer, generally 40K to 50K hours for two ball bearing fans and 30K to 40K for 1 ball / 1 sleeve fan. For ball bearing, because of processing precision and external pressure, the irregular rolling is larger and the material is harder. Therefore, it is easier to create resonance while the motor spinning at high speed.

RIFLE BEARINGI cant find much information about this type of bearing. But from what I found, rifle bearing is similar to sleeve bearing. However it has some special mechanism that will increase Life Expectance of the fan (still slightly less than ball bearing) and it is quieter than sleeve and ball bearing. Read

HERE for more

HYDRO BEARINGJust like rifle bearing, I cant really find too much information regarding this type of bearing. According to one website, it says that this type of bearing have a hydro oil membrane in between the shaft and the bearing. But, this type of lubrication is only effective while turning at high speed and at the same time produces low vibration. Other than that, this type of bearing also have longer life expectancy just like ball bearing.

EXTRASFor those who are interested in learning more about fans, you might wanna check out these links:

Fans FAQAnatomy of the Silent Fan CASE COOLING» Click to show Spoiler - click again to hide... «

While kopi and pasta-ing from MR.

AH GOO, I found a guy testing few different config on numbers of fans and the fans location positioning experiment. Below are the quoted

CONCLUSIONS from the website and it might not be like what we always thought. Please click

HERE to read more.

QUOTE

We would be lying if we weren't. It was our assumption that the tests with ALL the fans in operation would produce the best results but it didn't. Time to idle represents how effectively the configuration removes heat from the PC case. The shorter the time the better. CPU peak and idle as well as System peak and idle are easy to interpret. We would like to think that System temperature represents an average of how cool every component in a PC is.

*The top and rear exhaust produced the best CPU and System results but nearly placed last for time to idle. We tested three times for this result as we didn't believe the first two.

*A single rear exhaust fan produces the best results overall. This flushes the theory of more fans is better right out the door.

*A top only or top and front combination places in the middle of the pack for CPU and System peak cooling BUT does whisk away the heat in a very short amount of time.

*Even with no cooling fans besides the heatsink, heatsink size and type of fan can deliver good results.

By the way, I got another link thanks to our lowyat.net member

ham_revilo which talks about

CASE COOLING as well

QUOTE

This is an interesting

Battles of the Intel Stock Coolers link given by lowyat.net member

xk2.

QUOTE

Lately have been seeing people argueing about whether copper or aluminium is better. The answer lies

HEREQUOTE

Air Cooling giving temp reading of 2 degree celcius? Not a joke at all... See

HERE for more subzero air cooling

QUOTE

5 Thermal Paste Comparison Review:

Arctic Cooling MX-2,

Arctic Silver 5,

Tuniq TX-2,

Gelid GC1,

Ocz Freeze Please let me know via PM if there are any mistakes or noobness of mine

Below are the sites i have used as a reference and source of kopi

The Heatsink GuideBenchmarkreviews - Best Thermal Paste Application MethodsBenchmarkreviews - 33 Way Thermal Interface Material ComparisonT&T FANS FAQSilentpcreview - Anatomy of the Silent FanOverclockersclub - Coolermaster Neon LED Case Fans ReviewPC airflow and heat - a cooling guideTweak3D.net - Air Cooling GuideThis post has been edited by tkh_1001: Mar 11 2010, 10:01 AM

The Heatsink GuideBenchmarkreviews - Best Thermal Paste Application MethodsBenchmarkreviews - 33 Way Thermal Interface Material ComparisonT&T FANS FAQSilentpcreview - Anatomy of the Silent FanOverclockersclub - Coolermaster Neon LED Case Fans ReviewPC airflow and heat - a cooling guideTweak3D.net - Air Cooling GuideThis post has been edited by tkh_1001: Mar 11 2010, 10:01 AM

Sep 1 2008, 03:45 AM, updated 11y ago

Sep 1 2008, 03:45 AM, updated 11y ago

Quote

Quote

0.0230sec

0.0230sec

0.81

0.81

6 queries

6 queries

GZIP Disabled

GZIP Disabled