QUOTE(TitanRev @ Jan 20 2014, 03:08 PM)

» Click to show Spoiler - click again to hide... «

Open system, you vent into atmosphere. Running Open system you need to plugged off the opening at the intake manifold and the intake pipe with silicone end caps like below.

Closed system, you recirculate it back into the intake manifold but if your OCT is not baffled then your blow by gas will get sucked back into the intake manifold also because if you read my post in zerotohundred, I've mentioned that most OCT in the market is just empty canister without any baffled plate or mesh and the inlet, outlet of the OCT is just next to each other so how much blow by will have enough time to condense before get suck back in to the intake manifold from the outlet side due to vacuum from the intake...The oil vapor that gets into the OCT will only have an empty space to condense itself. IF like this the OCT is not performing at it's most efficient. Hence I put in SS wire mesh and extend the inlet tube to the OCT. 2 reason to do this, be it you running open/closed system. you increase the distance of the outlet opening and the inlet which effectively reduce the amount of blow by getting suck backed in. With the wire mesh put in and the hose extend the inlet to more than 3/4 into the tank. You create a bigger total area, further and blocked path for the oil vapor to get sucked back into the intake manifold.

Below is my CARBING OCT from my other car. Look at the amount of blow by it has captured because this OCT is not baffled also, you can see the return hose back into the intake manifold also become dark brown colour already. Also placing your OCT as far as possible from heat source also helps the canister to stay cold and helps condense the oil vapor that goes into the canister before it can escape from the canister. Simple example, when you boil water if you don;t close the lid on the pot, the water will dry up in the pot, When you put the lid of the pot over the steam, you will start to see steam condensing over the lip and soon become water droplet. The same principle applies to OCT also.

Closed system, you recirculate it back into the intake manifold but if your OCT is not baffled then your blow by gas will get sucked back into the intake manifold also because if you read my post in zerotohundred, I've mentioned that most OCT in the market is just empty canister without any baffled plate or mesh and the inlet, outlet of the OCT is just next to each other so how much blow by will have enough time to condense before get suck back in to the intake manifold from the outlet side due to vacuum from the intake...The oil vapor that gets into the OCT will only have an empty space to condense itself. IF like this the OCT is not performing at it's most efficient. Hence I put in SS wire mesh and extend the inlet tube to the OCT. 2 reason to do this, be it you running open/closed system. you increase the distance of the outlet opening and the inlet which effectively reduce the amount of blow by getting suck backed in. With the wire mesh put in and the hose extend the inlet to more than 3/4 into the tank. You create a bigger total area, further and blocked path for the oil vapor to get sucked back into the intake manifold.

Below is my CARBING OCT from my other car. Look at the amount of blow by it has captured because this OCT is not baffled also, you can see the return hose back into the intake manifold also become dark brown colour already. Also placing your OCT as far as possible from heat source also helps the canister to stay cold and helps condense the oil vapor that goes into the canister before it can escape from the canister. Simple example, when you boil water if you don;t close the lid on the pot, the water will dry up in the pot, When you put the lid of the pot over the steam, you will start to see steam condensing over the lip and soon become water droplet. The same principle applies to OCT also.

QUOTE(TitanRev @ Jan 20 2014, 03:15 PM)

» Click to show Spoiler - click again to hide... «

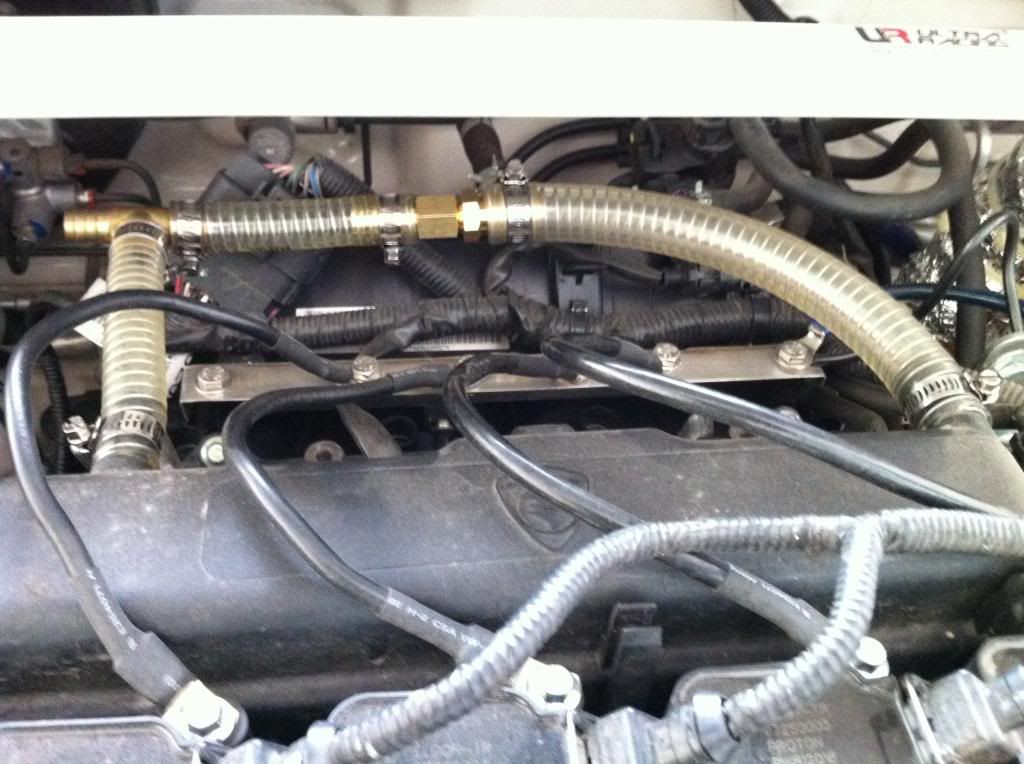

Notes to add, on the gaga, the return inlet to the intake manifold will be difficult to hook up a hose clamp for a closed system due to the size of the inlet back into the intake manifold is different from the outlet of the rocker cover. I try to do a closed system but when I found out the return opening was smaller than the hose, I was stun at 1st..thinking how to solve the problem since it was SAT evening and shops are closed so what I did is I went and found some old rubber hose from my other cars which I don't used them anymore and cut a piece and fit a ALU plug over 1 end of the hose before I plug it into the return opening. Like below. The ALU plug piece I have was supplied with my CARBING OCT which I didn't use it so I used it on this occasion. If you do not have or not able to get a silicone plug caps, you can plug the end of the rubber hose with a bolt also but make sure the size is bigger then the hose ID so that it fits tightly into the rubber hose.

1 more question works engineering got optional can put breather filter.. so if do open system still need it? or the breather filter only juz for show only?

Jan 20 2014, 03:28 PM

Jan 20 2014, 03:28 PM

Quote

Quote

0.0332sec

0.0332sec

0.61

0.61

6 queries

6 queries

GZIP Disabled

GZIP Disabled