Most of the time when we buy headers we see the exterior most of the time. The weld on the exterior and the bending but most people forgot or do not know other than checking the exterior, the interior of the headers is the most important thing and what sets the few K headers from the few hundred one.

I spent some time today to went to different exhaust shop and snap pictures of the headers they are selling but I won't name the shop out or the brands of these headers (some don't even have brands)

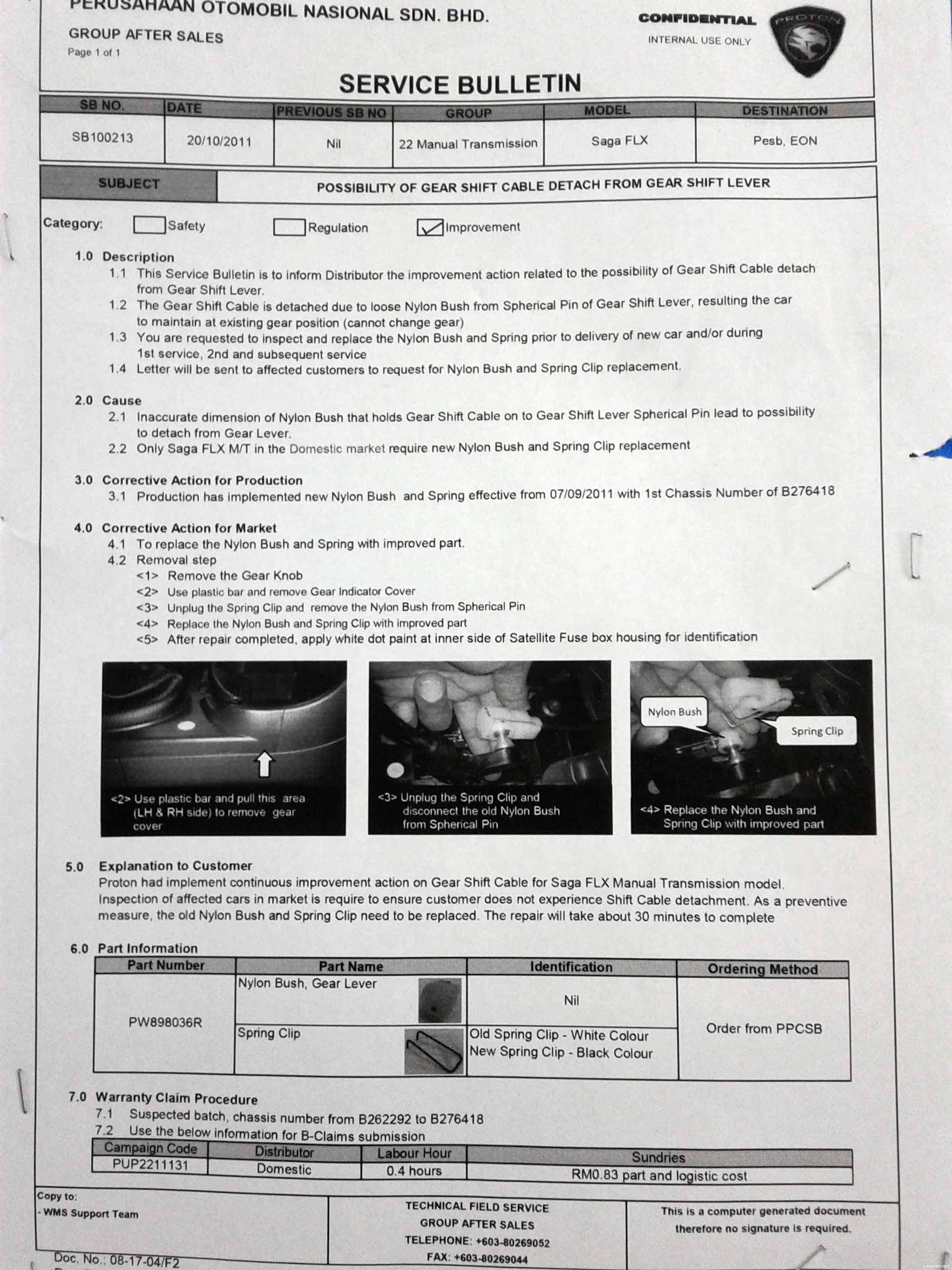

Picture A

Below is 1 of the S.Steel extractor I saw and snap a pic of it. Notice any problem with it? It's ok if you can't see it. I will tell you. Look at the joining point of the runner to the mounting plate on the left and to the right. See the difference? This is something you don't want to have. The left runner is not fully slotted in to have a flush fitting with the mounting plate while the right one is fully slotted in. This little thing sometime is not noticeable but it will make a bit of difference when you put into your engine. Although the left runner was been slightly ported but it still have a step or ridge this will cause air flow turbulence on the exhaust gas. This is clearly a workmanship error.

Picture B

This one is from another local maker. This one you can see that the manufacturer they just weld the edge of the primary runners onto the mounting plate compare to the previous one which slot into the mounting plate and weld on the outside only. A good extractor maker will only weld outside of the primary runners and not weld on the joints as the welded area will have bumps and uneven surface which will penetrate into the inner side of the runners. There's some bad things when you have weld like this. 1. The welded area will crack and opens up after sometimes of use due to vibration, resonance and constant expansion and contraction of the steel. 2. Rust will happens on the inner side of the runners due to the weld.

So next time you go to an exhaust shop to change your headers, please ask to see the actual items before fitting and check the interior part. If it does not satisfy you then just don't change it. Although the part might give you improvement but the part is not performing close to 100% efficiency. If you have the guts and skill then you can buy a better one with only slight bumps bring it home and port it before you DIY install into your car.

Now, if changing to aftermarket headers is not in you list due to price or some other reason there's another way to improve the flow of your stock extractor.

As we all know stock headers are produced in mass quantity and with cost in mind so the fitment tolerance is surely to be higher than those good performance header. Most of the time the exhaust port opening of the cylinder block is bigger than the exhaust manifold (due to fitment tolerance and mass production). Most performance shop also offers only port and polish for the cylinder block but never the exhaust manifold. So below I show you how to port your stock headers exhaust opening to be the same as your exhaust port on the block.

You can refer to the link here to get an idea how it's done.

http://forums.vwvortex.com/showthread.php?3603731

After I've done the DIY to my 206 few years back it felt lighter on the initial to low rev. That's what my butt dyno tells me since I don't have an actual dyno. The differences might be small but for a small cc car but every drop of power that can squeeze out will make a difference. The tools you need also not much if you don't have a Dremel or die grinder a power drill will do also and patience. Also due to the porting process you get some venturi aka cone shape effect which is good. Such porting is not popular in Malaysia and mostly DIYers will do it rather than shop.

Hope the information shared here is beneficial to all.

This post has been edited by TitanRev: Jun 22 2013, 05:13 PM

Jun 22 2013, 05:06 PM

Jun 22 2013, 05:06 PM

Quote

Quote

0.0334sec

0.0334sec

0.31

0.31

7 queries

7 queries

GZIP Disabled

GZIP Disabled