Total Productive Maintenance (TPM),

hazard prediction training KYT (Kiken Yochi Training),

Near miss

and

Kaizen

https://www.slideshare.net/hishamrizvi1/six-sigma-24557303

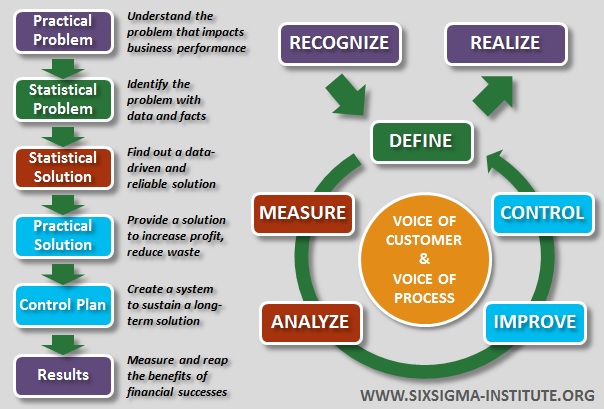

Six Sigma and DMAIC Methodology Overview

What is Six Sigma?

Lean Manufacturing

Lean Manufacturing’s roots lie with the Toyota Production System (also referred to by its acronym TPS;

or as JIT, which stands for Just-In-Time manufacturing)

and the principle of focusing

on the value provided to the customer and

reducing waste, where waste is defined

as anything that does not directly provide value.

In the context of Lean Manufacturing and the TPS,

waste falls into three categories:

Muda: The waste of work being done that is not adding direct value

Muri: Waste due to overburdening people or assets beyond their limits

Mura: Waste resulting from fluctuations in work, or unevenness

The intent of Lean Manufacturing programs is to identify and reduce waste across all categories. Value Stream Mapping, the exercise of describing the steps that go into making a manufactured product and assessing the value associated with each step, is a vital tool in this process as it helps to identify the current state of manufacturing operations, the desired future state, and the business value of making progress towards the future state.

Six Sigma (6σ) is a set of techniques and tools for process improvement. It was introduced by American engineer Bill Smith while working at Motorola in 1986.

Jack Welch made it central to his business strategy at General Electric in 1995. A six sigma process is one in which 99.99966% of all opportunities to produce some feature of a part are statistically expected to be free of defects.

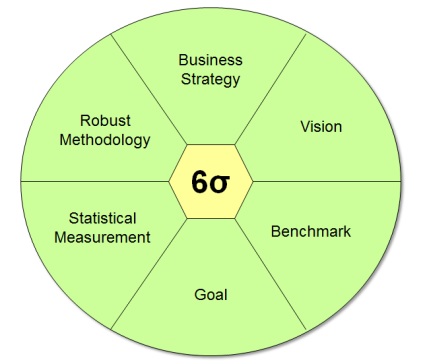

Six Sigma is:

A Business Strategy: Using Six Sigma Methodology, a business can strategize its plan of action and drive revenue increase, cost reduction and process improvements in all parts of the organization.

A Vision: Six Sigma Methodology helps the Senior Management create a vision to provide defect free, positive environment to the organization.

A Benchmark: Six Sigma Methodology helps in improving process metrics. Once the improved process metrics achieve stability; we can use Six Sigma methodology again to improve the newly stabilized process metrics. For example: The Cycle Time of Pizza Delivery is improved from 60 minutes to 45 minutes in a Pizza Delivery process by using Six Sigma methodology. Once the Pizza Delivery process stabilizes at 45 minutes, we could carry out another Six Sigma project to improve its cycle time from 45 minutes to 30 minutes. Thus, it is a benchmark.

A Goal: Using Six Sigma methodology, organizations can keep a stringent goal for themselves and work towards achieving them during the course of the year. Right use of the methodology often leads these organizations to achieve these goals.

A Statistical Measure: Six Sigma is a data driven methodology. Statistical Analysis is used to identify root-causes of the problem. Additionally, Six Sigma methodology calculates the process performance using its own unit known as Sigma unit.

A Robust Methodology: Six Sigma is the only methodology available in the market today which is a documented methodology for problem solving. If used in the right manner, Six Sigma improvements are bullet-proof and they give high yielding returns.

Lean manufacturing

Lean manufacturing, or lean production, is a production method derived from Toyota's 1930 operating model "The Toyota Way" (Toyota Production System, TPS). The term "Lean" was coined in 1988 by John Krafcik, and defined in 1996 by James Womack and Daniel Jones to consist of

five key principles;

'Precisely specify value by specific product,

identify the value stream for each product,

make value flow without interruptions,

let customer pull value from the producer,

and pursue perfection.'

This post has been edited by plouffle0789: Jul 24 2020, 03:51 PM

Jun 16 2020, 12:12 PM, updated 6y ago

Jun 16 2020, 12:12 PM, updated 6y ago

Quote

Quote

0.0394sec

0.0394sec

0.68

0.68

5 queries

5 queries

GZIP Disabled

GZIP Disabled