PS - pls check the link below which shows an ORI crankpully...

http://www.zerotohundred.com/newforums/eng...rank-pully.html

Lightened Crankpully / Lightened crankshaft, Come and discuss

|

|

Nov 6 2008, 01:10 PM Nov 6 2008, 01:10 PM

Return to original view | Post

#1

|

Junior Member

210 posts Joined: Jun 2007 From: Kuala Lumpur |

could someone confirm whether our stock MMC Wira 1.5 crankpulley comes with the harmonic dampener?...cos's reason why i'm asking is that i could not see the rubber dampener on the pulley...Sifu's help is highly appreciated...

PS - pls check the link below which shows an ORI crankpully... http://www.zerotohundred.com/newforums/eng...rank-pully.html |

|

|

Nov 7 2008, 08:02 AM Nov 7 2008, 08:02 AM

Return to original view | Post

#2

|

Junior Member

210 posts Joined: Jun 2007 From: Kuala Lumpur |

but has anyone tred to a look at their stock crankpully to see whether there is any dampener there, especially for Protons 4G1*?

|

|

|

Nov 19 2009, 02:01 PM Nov 19 2009, 02:01 PM

Return to original view | Post

#3

|

Junior Member

210 posts Joined: Jun 2007 From: Kuala Lumpur |

did a search on the most elusive question about our harmonic damper where at last manage to find some hard facts...

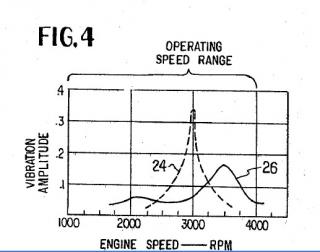

http://www.freepatentsonline.com/4302986.html i would like to quote a few statements from above article :- "As the crankshaft is turning, each incremental application of torque, as occasioned by rapid fuel combustion in a cylinder, results in a slight acceleration of the metal adjacent the crank arm. When the metal recovers, due to its natural elasticity or resilience, it rotates slightly in the opposite direction. Such forces often result in torsional vibrations in the shaft. In a typical instance of torsional vibration, an engine crankshaft turning at a rate of 3000 r.p.m. simultaneously executes angular vibrations of an amplitude of from one-fourth degree to one degree at a frequency of 150 to 250 cycles per second." "Thus whenever any rotary mass, such as a torsional vibration damper, is added to the crankshaft of an engine, the resonant frequency of that crankshaft is lowered. Such lowering may bring critical resonant vibration orders of the crankshaft near or within the operating range of speeds of the engine". "It will now be apparent to the reader that the inertia of a rotary mass fixed to the crankshaft, for the purpose of completing a typical damper assembly, should be as small as possible. In this way, the crankshaft resonant frequencies may, in certain applications, be maintained as far as possible from the engine firing related frequencies." FIG. 2 illustrates the action of the addition of a torsional vibration damper of the type shown in FIG. 1 on a resonant frequency response of the typical crankshaft in an internal combustion engine, the ordinate showing torsional vibration amplitude being in tenths of a degree. FIG. 3 is a view similar to FIG. 2 and illustrates a torsional vibration damper tuned to a frequency above an optimum frequency. FIG. 4 is a view similar to FIG. 3 and illustrates an arrangement of a torsional vibration damper tuned to a frequency below an optimum frequency. FIG. 5 is a view similar to FIG. 1 and illustrates the effect on torsional vibration behavior of the addition of a typical cast iron hub to a crankshaft. FIG. 6 is a view similar to FIG. 2 and illustrates the change in frequency response of a crankshaftdamper assembly with the use of a damper employing a plastic hub of this invention. FIG. 7 is a view similar to FIG. 5 and illustrates an optimum manner of tuning the plastic hub vibration damper of this invention. hence, in summary, can we conclude that if we use a non-dampened LCP, would the crankshaft resonant frequency be moved to the higher RPM beyond 4,000 which is then is safe to be used for our cars? Attached thumbnail(s)

|

| Change to: |  0.0158sec 0.0158sec

0.40 0.40

7 queries 7 queries

GZIP Disabled GZIP Disabled

Time is now: 6th December 2025 - 04:14 AM |