Been sleeping for on my case mod since 2011

https://forum.lowyat.net/topic/1738405

from like this:

to

Man! Did I let it go to rot.....

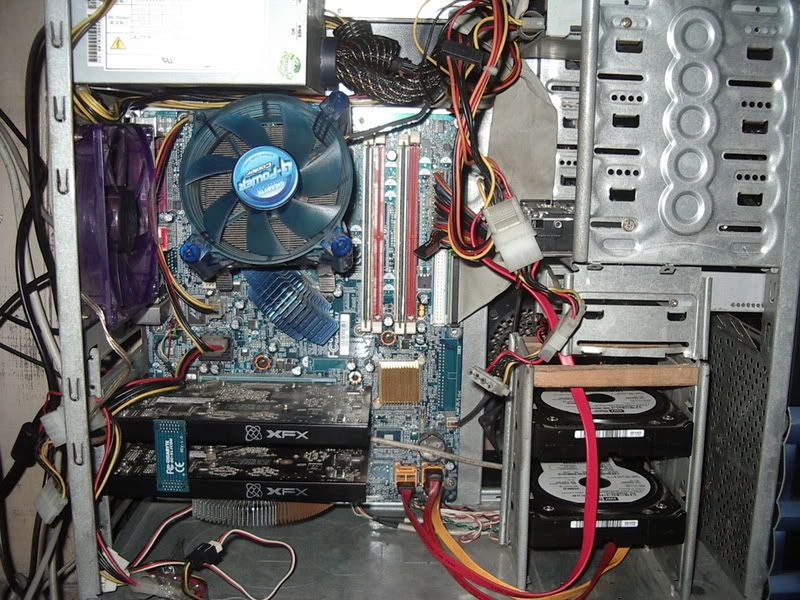

What you guys are seeing here..

As of September 2014, my rig:

Intel Core i7 2600K

Asrock P67 Profesional (fatal1ty) motherboard

4x 2GB DDR 1600MHz

2x Nvidia 9600GT 512MB

4+ HDD

Seasonic S12D 750W PSU

Dell U2414h (pictured here is Dell 2407WFP HC, which retired early Aug 2014)

What really re-boot back my old project?

This https://forum.lowyat.net/index.php?showtopic=3323198&hl=

(for future reference if thread pruned, the link above goes to a selling page of MSI GTX680 Lightning at irresistible prices, for me at least)

And further compounded with the viewing of Nvidia Mod 24 (an event to commemorate the release of GTX980, with 3 teams to mod case withing 24hrs, and stream live in twitch)

https://www.google.com.my/search?client=ope...WHcvM8gWPv4LoBg

I got the GTX680 a week back and till now not yet connected...

» Click to show Spoiler - click again to hide... «

RT8081 liked this post

Sep 26 2014, 11:49 AM, updated 10y ago

Sep 26 2014, 11:49 AM, updated 10y ago

Quote

Quote

0.0279sec

0.0279sec

0.74

0.74

5 queries

5 queries

GZIP Disabled

GZIP Disabled