(~Star War Theme~)

2007 to be exact

Got my self a new system

the specs

Pentium D 930 (bought from an "acquaintance")

Gigabyte GA-8N-SLI (the cheapest store-bought SLI mobo I can afford back then)

2x7600GT in SLI

etc...

Housed in THE CHEAPEST-THINNEST-WOBBLY-CASING that is modeled after Alienware style

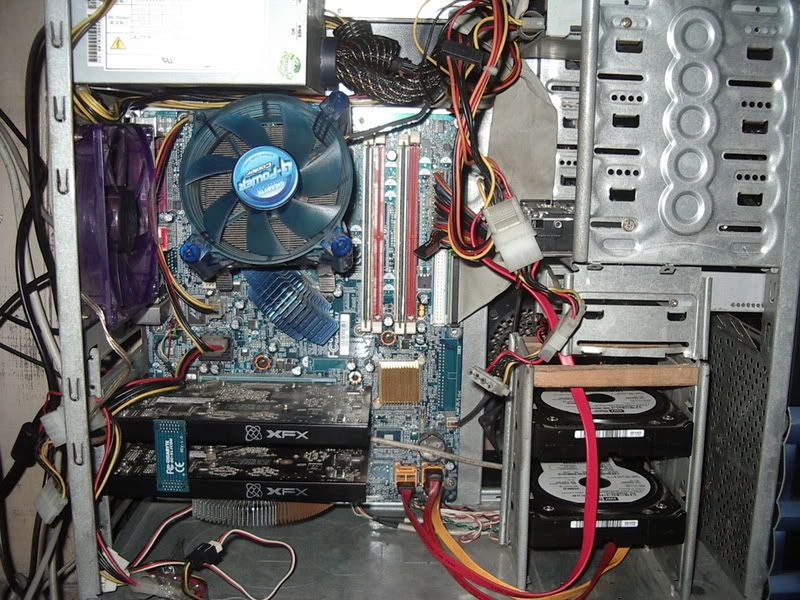

Some Pic Circa 2008

This is the side of the casing. As you can see, some mods done here back then

- The fan Grill cut roughly

- Fan hanging from the DVI plug to draw out air

The Moneh Shot

Turned the HDD cage 90 degrees (an absolute error!!)

Then 2008 passes

so does 2009, swamped with job responsibility

(some where in that year got to go to Bologna, Italy

2010 was a B!TCH and so we arrive to 2011

Let me recap what was to be of my rig

2007

Intel Pentium D 930

GA-8N-SLi

1GB Samsung DDR2

XFX 7600GT

14" El-cheapo LCD

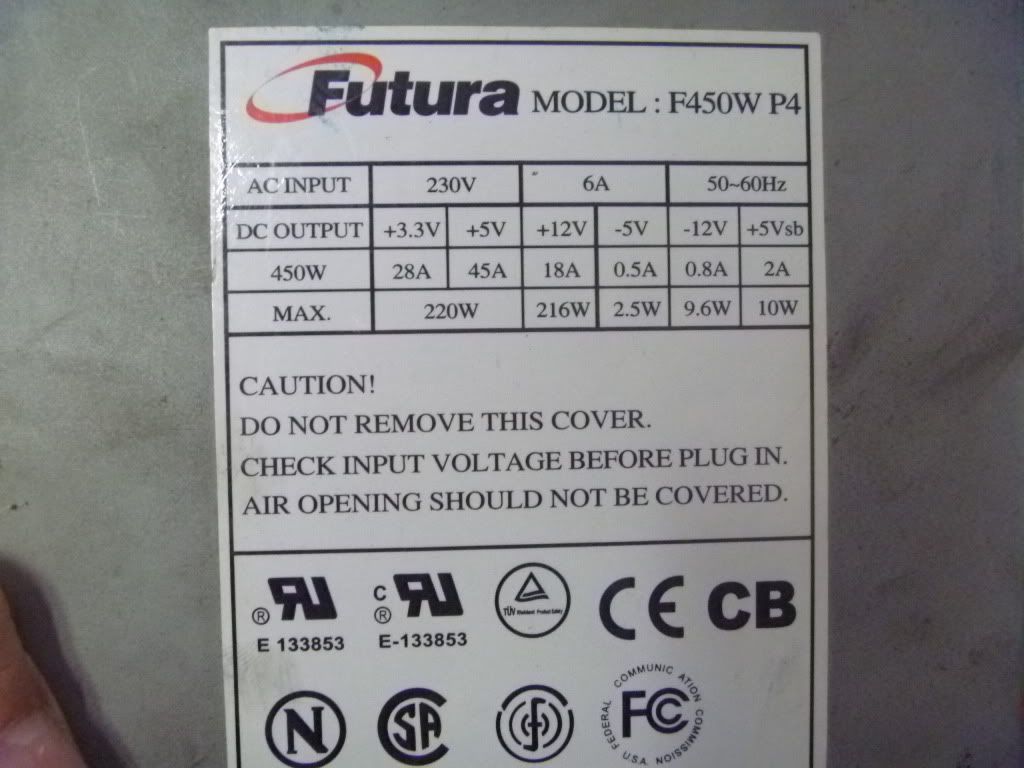

Enermax 460W PSU

Gigabyte G-Power HSF

Feb 2008

Intel Pentium D 930

GA-8N-SLi

XFX 7600GT + XFX 7600GT

Enermax 460W PSU

Gigabyte G-Power HSF

Mar 2008

Intel Pentium D 930

GA-8N-SLi

Enermax 460W PSU

Gigabyte G-Power HSF

Aug 2008

EEE PC 901

Sony E W595

etc

Lay low for a year, then...

Nov 2009

Intel Pentium D 930

GA-8N-SLi

Gigabyte G-Power HSF - Done some mod (change to Delta Fan)

1H of 2010

Intel Pentium D 930

GA-8N-SLi

Gigabyte G-Power HSF -Done some mod (change to Delta Fan)

2H of 2010

was skulking around for a x58 system

Got a deal to Get Asrock x58 system but then the deal fell through

and by "LUCK" my GA-8N-SLi mobo expires..

so got myself an interim mobo, a Asus P5B to tide me over while my other deal is in the pipes

The system as of now

Intel Pentium D 930

GA-8N-SLiAsus P5B

Gigabyte G-Power HSF -Done some mod (change to Delta Fan)

Expected system @ Mar 2011

Intel Core i7 2600K

Asrock P67 Extreme6

8GB G.Skill RipJawsX 1600MHz

xPertVision 9600GT+ Galaxy 9600GT

24"Dell 2407WFP HC

Seasonic S12D 750W

Mod G-Power to be a Tower HSF

So With a new system coming, I ain't gonna stick it in a crappy casing right?

if to be a crappy casing, it would have to by my OWN CRAPPED CASE!

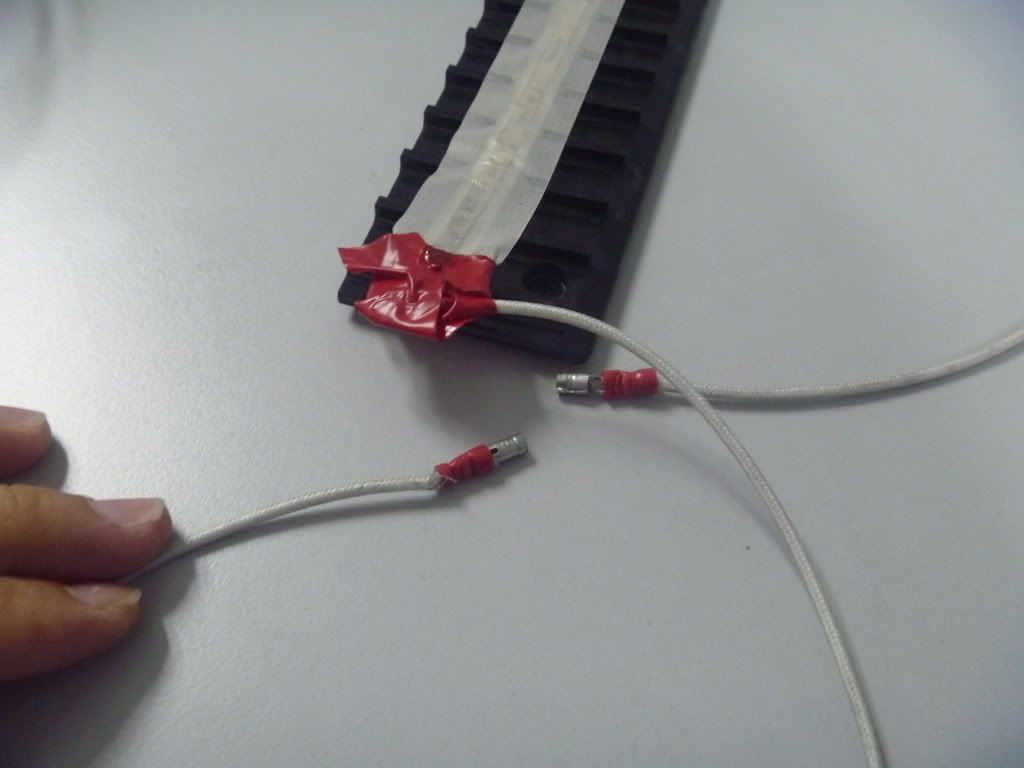

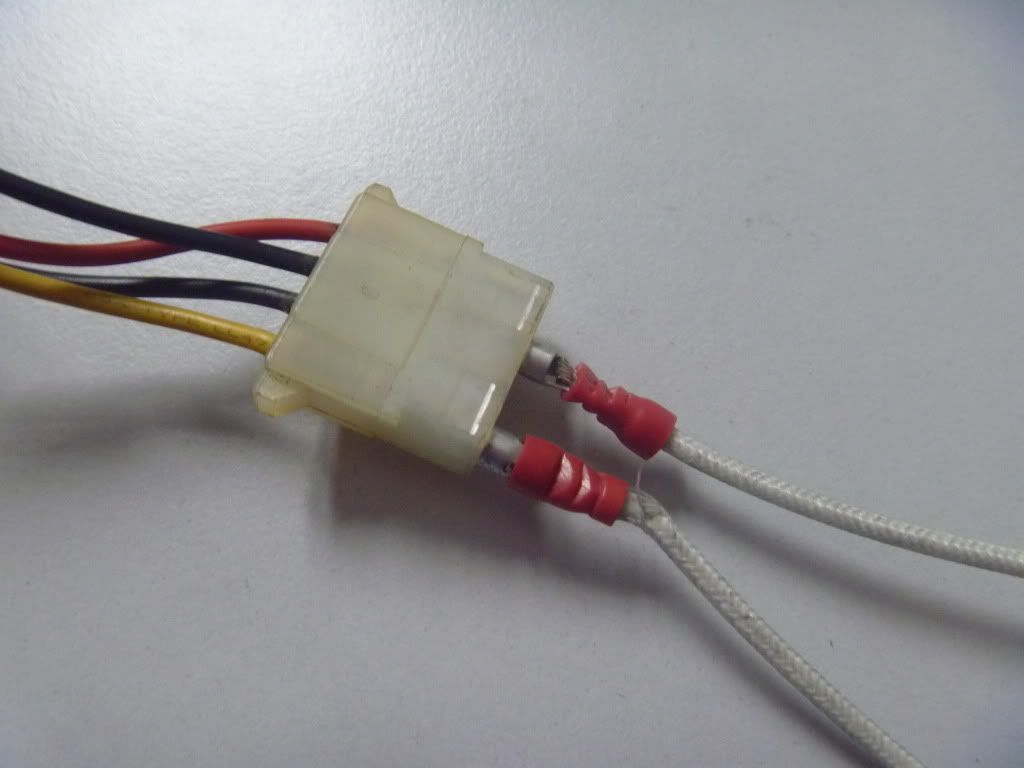

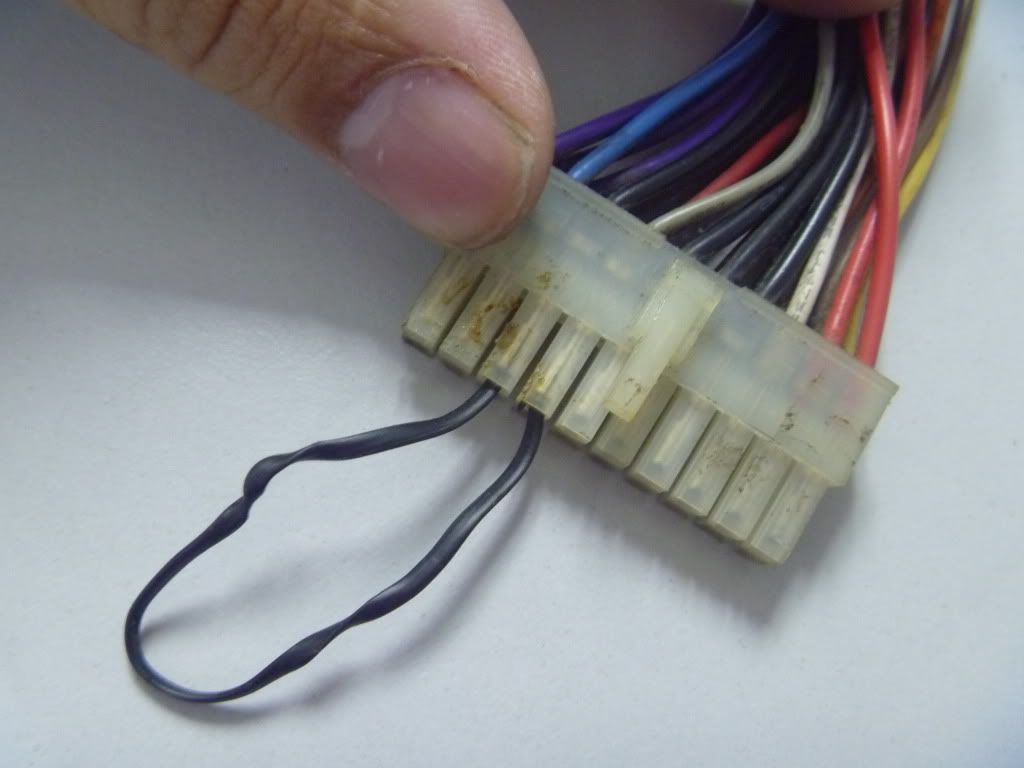

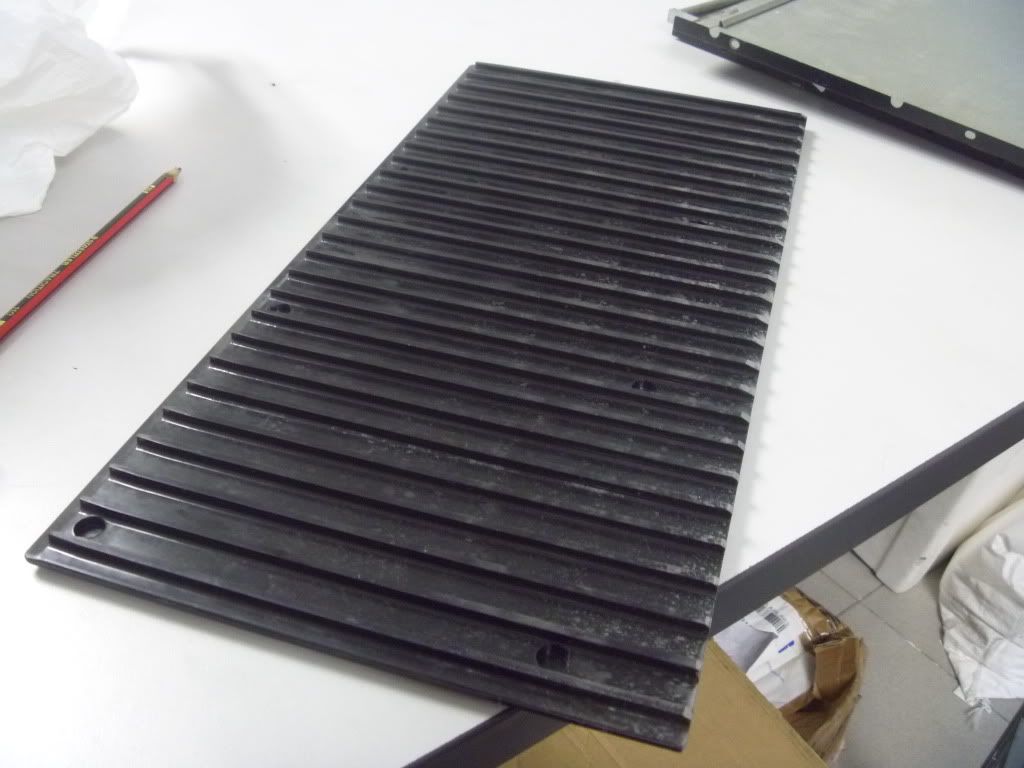

The mod So Far

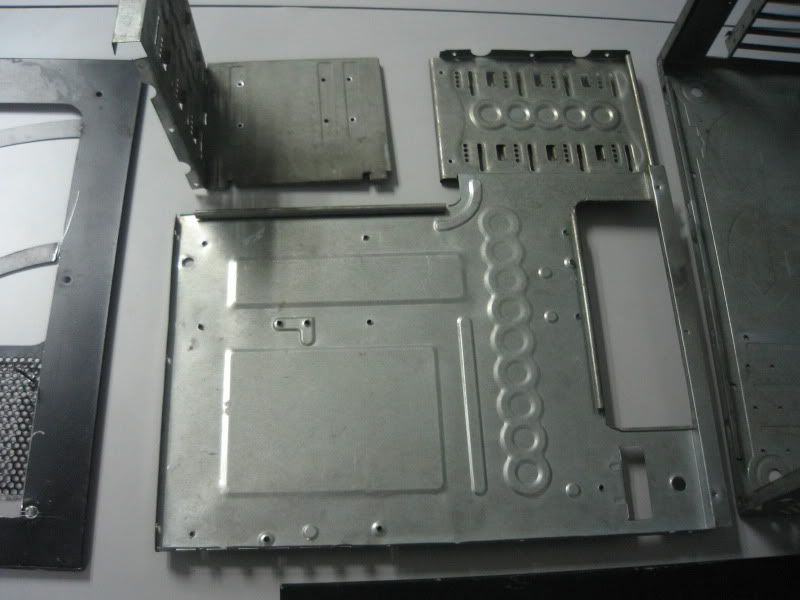

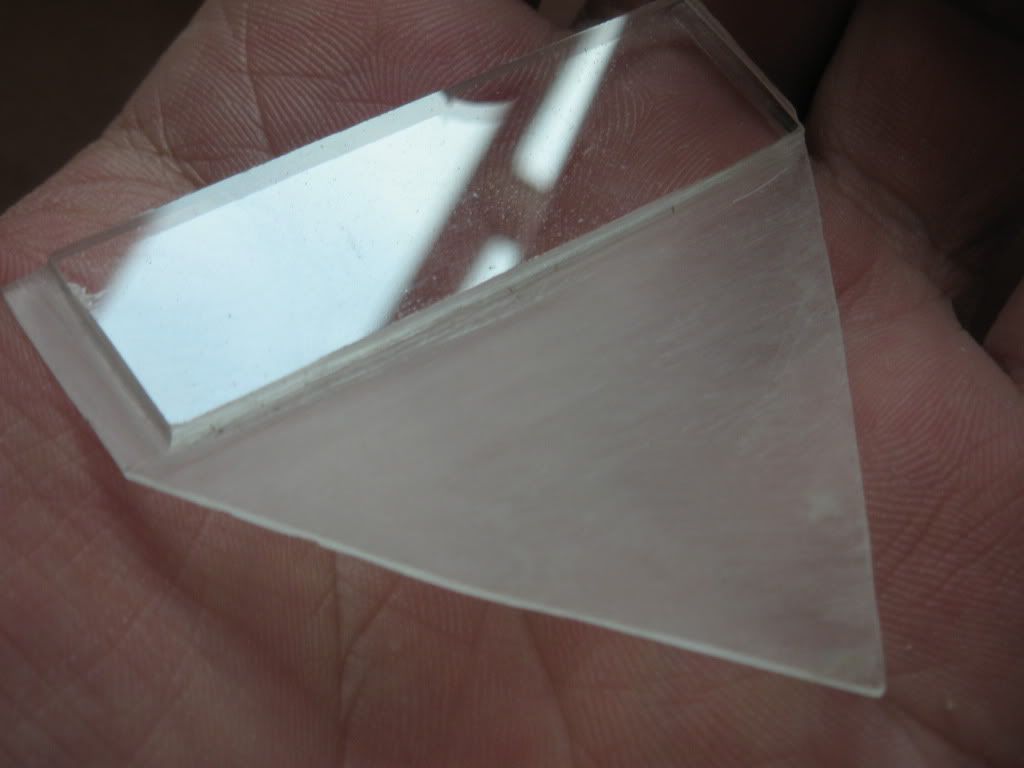

The case Dismantled until dismantle-able

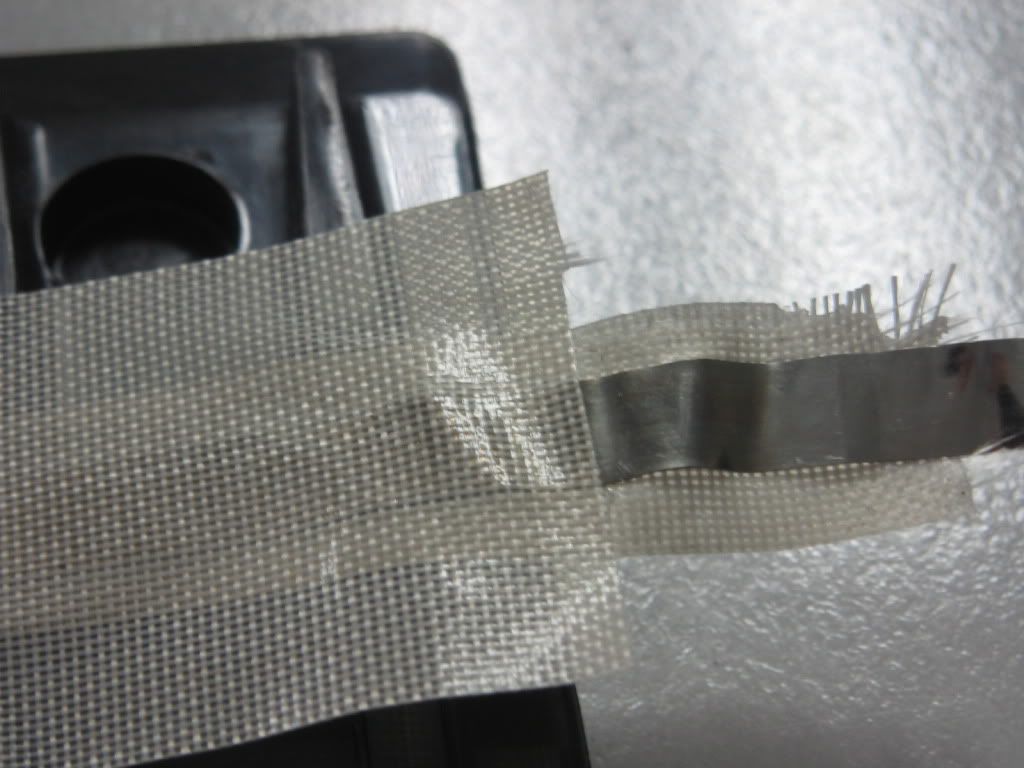

The side with the cheesy stuff cut out (with a grinder)

the mobo tray stuck with the 5.25" cage... ah well have to think of a way

the nearer view of the main body

ya I know it's crap, the outlet fan need retouch, the whole rig need reinforcement

and it badly need some new coat of paint

that is for now of the rig pictures

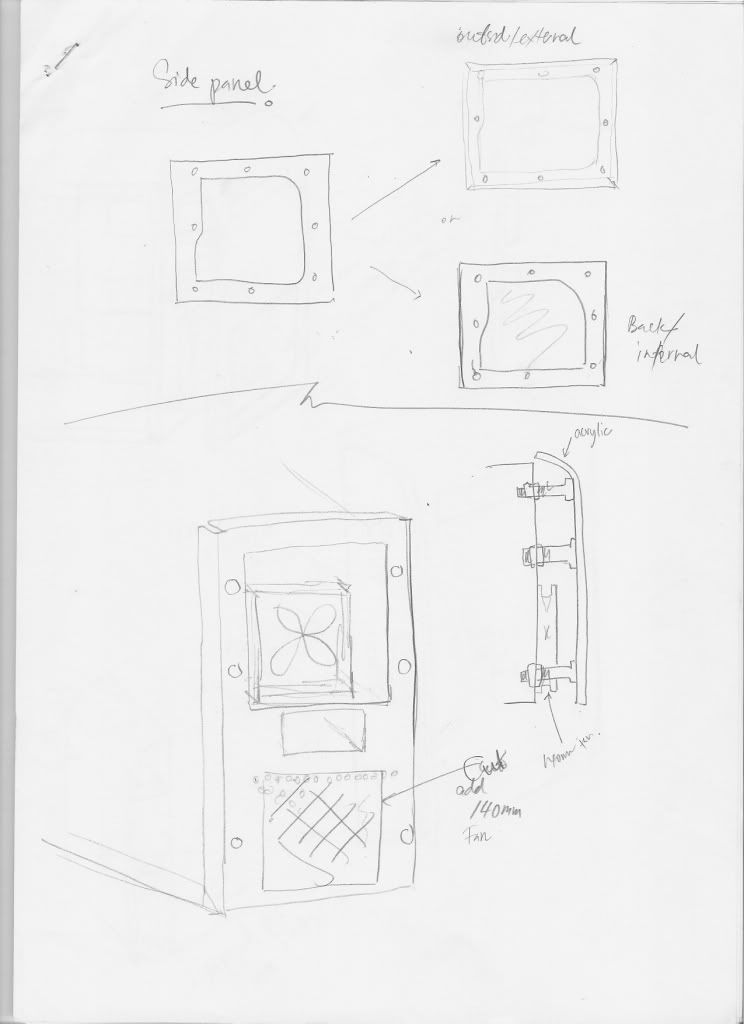

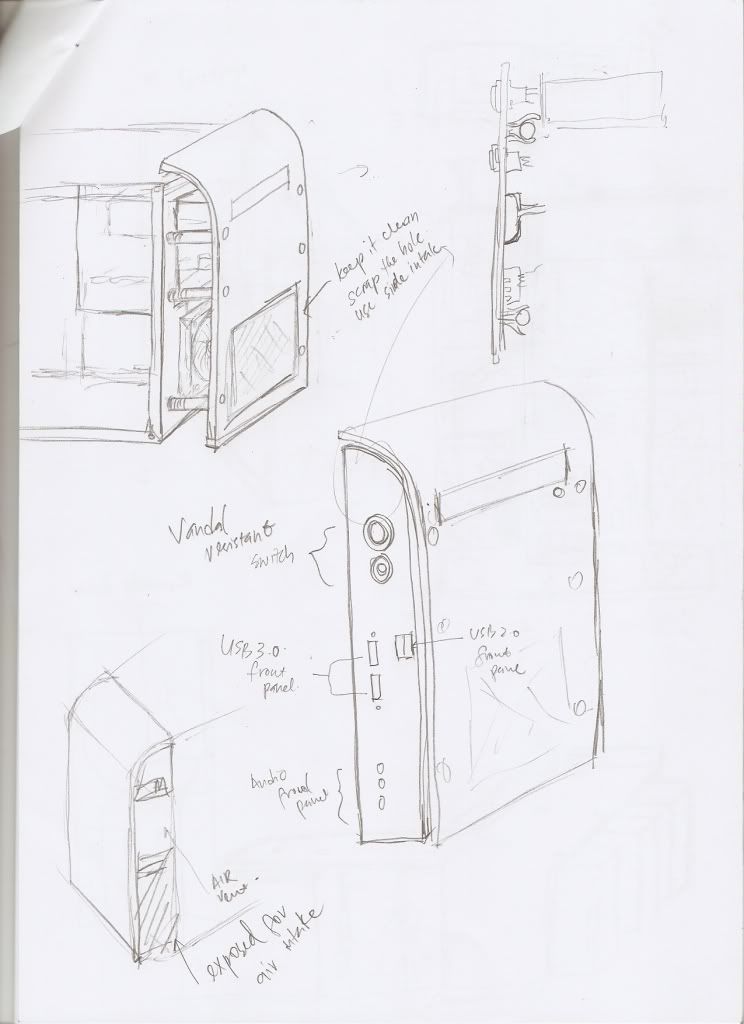

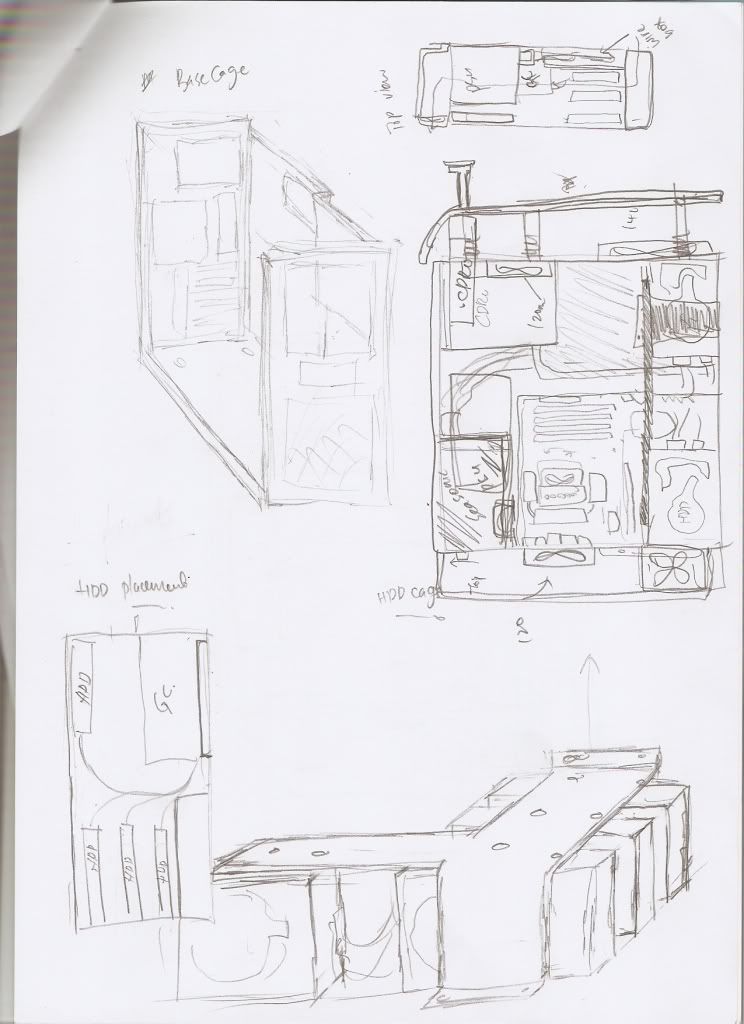

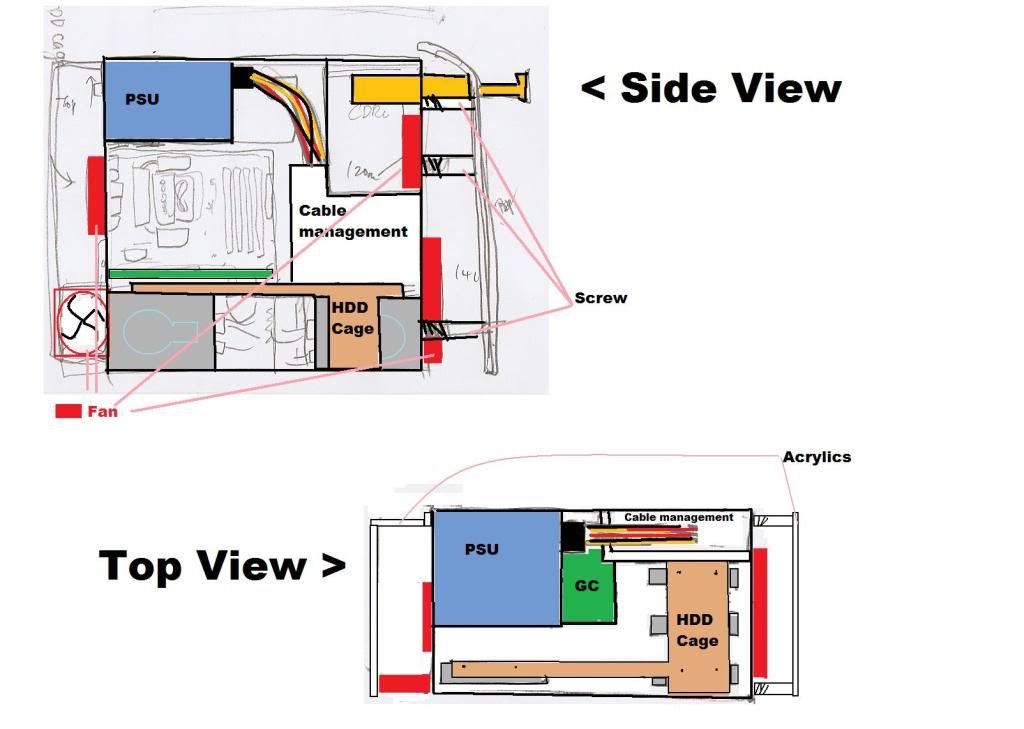

the next post is dedicated for some plan drawings (freehand style)

thank for viewing

I will try my best to drag it out the best i can

make it like an EPIC GRANPA story

This post has been edited by mcchin: Mar 17 2011, 03:42 PM

Jan 31 2011, 12:59 PM, updated 12y ago

Jan 31 2011, 12:59 PM, updated 12y ago

Quote

Quote

\

\

0.0259sec

0.0259sec

1.44

1.44

5 queries

5 queries

GZIP Disabled

GZIP Disabled