QUOTE(amir_tengkorak @ Oct 12 2011, 09:17 AM)

JOM! but...where u guys staying leh?

im in desa petaling area, a bit far but no problem coming sunway

QUOTE(low yat 82 @ Oct 12 2011, 09:27 AM)

kanasai. meet up around sunway la.... wan go dyno ma... uponskyriver u dyno d? mayb we go dyno la..huhu.. easier to chat wit graph infront us

no havent done, poket still got holes to sew haha but if all wanna do i think i can stretch my budget a bit hehehe

QUOTE(caarzee @ Oct 12 2011, 03:44 PM)

hi

I drive a Xtrail 2.0 2005 year AT car, NA with K&N drop in. I've been looking around to upgrade my exhaust. The stock setup is currently 4-1, cat, bullet, (looks like U-shape) muffler . I'm looking for a everyday city drive, therefore are looking at 4-2-1 setup. My usual AT drive, autogear changes on around 2.5k-3k rpm. at most, i'll hold it till 3.5k rpm but never passes that. my drive is always below 140kmph on highway, and city about 100kmph. I'm looking for torque-y at lower rev and for faster speed recovery without the sacrifice of FC. as the chinese thinking goes, better if can improve on FC along with the rpm powerband. current FC is about 7.6km/ltr or 13L/100km. ideally, I am looking at 11L/100km or 9km/ltr.

the car specs are as follows:

Displacement (cc): 1998

Arrangement and No. of cylinders: Inline 4-cylinder

Type of combustion chamber: Cross-flow, pentroof

Valve mechanism: Chain-drive DOHC with 4 valves/cylinder

Fuel system: Port injection

Bore x stroke (mm): 89.0 x 80.3

Compression ratio: 9.9:1

Valve head diameter (mm): Intake: 35.5; Exhaust: 30.5

Cylinder bore pitch (mm): 97.0

Crankshaft pin-journal diameter (mm): 45.0

Crankshaft main-journal diameter (mm): 55.0

Connecting rod length (mm): 152.9

BTDC: 26

ABDC: 30

BBDC: 29

ATDC: 3

(see

http://www.4freeimagehost.com/uploads/fb412ebc1dee.png)I had been reading some of the forum replies (of recent ones), and this is just based on my understanding,

1) I need a (2.0 cc * 2L =) 4L bullet volume?

2) stick with 1.6" diameter pipping and stock muffler (i think it's U-shape)?

3) i don't think i want to go for hotbits due to rumours of "cracks".

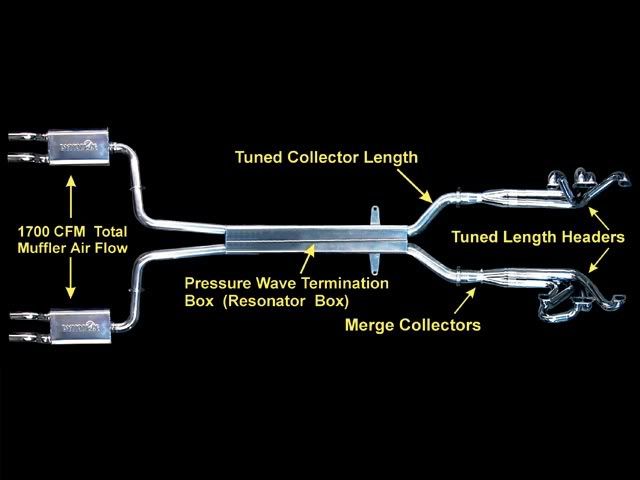

4) how do I go about calc the tuned length of extractor and collector, or length before the termination box ie bullet/midbox? Staying at 3500RPM, and I played around with the online calculators, it was recommended that I'll go with extractor header of 48" (15"+33"). Is this correct? I am still at loss how to go about getting the length of collector.

5) I'm leaning against taking out the cat, and if I don't, kind of defeat the whole purpose right?

6) what will be your recommendation for the whole setup?

thanks.

mine is close to luqmanz result, with BBDC of 29 degree, these are the results:

tuned rpm - 3000 , exhaust port length+header + downpipe length before bullet = 59"

tuned to engine max torque rpm 4000, total length of 44.5"

i suggest u do it shorter by 2" because this length includes the port length inside ur engine head as well

im not sure whether im getting this right but since u can hold maximum of 3.5k rpm then shift gear, probably best to tune it to run at around 3k so during upshifting, the rpm will drop to around 3k which is near to the tuned setup rpm so hopefully torque can be sustained longer across gears and rpm without having engine to push extra to climb back to tuned rpm everytime gear changes

but ur engine has 4k and 6k for max torque and max hp respectively so makes me wonder should u tune the exhaust to these rpm? haha but come to think about it, no matter how powerful the engine is, the power delivered to the wheel is still governed by the gearbox so 3k is probably a good start

if u are willing to further trial and error, get the longer 59" one first so in case u need more power at higher rpm, just cut it shorter to the next tuned rpm and place the bullet there. if u start shorter then later u will need to add more length in case u need torque at lower rpm, welds will be all over the downpipe area and does not look nice especially these parts are where power is being unleashed the most hehe

when u look for the 4-2-1, pay attention to the primary pipe size, i have read that good ratio for primary size to port size is around 1.15, i.e. if port diameter is 1.2" then best primary pipe will have around 1.4" in diameter but generally u will see bigger than this so get whichever close enough. also there should be at least 2" of straight line at each primary pipe on the header in line with ur exhaust port, if they are bended down straight away after the flange then its not really good in design. both these features improve anti-reversion of the header design to prevent exhaust gases going back to the chamber especially at idle and low rpm when gases are moving slow

pay attention to the merge collectors too, look inside for casting marks and merge quality. good header will have long and smooth merge at every collector i.e. at 4-2 merge and 2-1 merge collectors. smooth long collector improves the flow easeness and most importantly, although pressure wave reflection is weaker but the reflection duration will be lengthened due to the long merge and powerband is wider. short collector will have narrower powerband but in return pressure reflection will be much stronger, good for high rpm take off, not really for speed recovery in city drive

so, to sum up:

-4-2-1,

-1.6" stock pipe

-4L bullet/midbox or if u cant fit them under the car, 2.5L or 3L will also do the job if u are not going for 5k and above. 4L makes sure that the tuned length is kept until ur max engine rpm, if u dont go that high, lower than 4L still ok. but make sure u keep at least 0.5" diameter difference between bullet and downpipe. say if u use 1.6" downpipe, try get something like 2.5" bullet which has 0.9" difference. if u use 2" bullet, at one point im afraid the bullet will be considered as extension to the downpipe , the length will go out of tune so efficiency is lost there.

- im not sure the stock muffler is capable of flowing the gas ur engine expelling due to manufacturer noise regulation. they always compromise exhaust efficiency for a lot quiter sound and low cost in muffler design but stick to the stock first and see how the new upgrade does to u, let us know the result and we come up with another proposal for u

sorry for long explaination but i just thought u deserve to know at least the essentials

QUOTE(weeen11 @ Oct 12 2011, 05:29 PM)

Wanna ask some sifu here, which header is better for auto car??? 4-2-1 or 4-1? And also S-flow or Straight flow muffler better ?

depends on ur driving style and engine speed preference. 4-2-1 always good for torque sustain at high gear cruising and speed recovery from stopping and braking and 4-1 always good for low gear pickup and straight line acceleration to max rpm.

use sflow if u want cheap solution to noise issues and straight flow if u are after efficiency. power in straight flow setup is easier to predict, sflow can be hard to predict, sometimes u satisfied sometimes not. im always a fan of silent straight flow

QUOTE(kokhing520 @ Oct 12 2011, 06:06 PM)

I want to ask ... Which distance is best for auto 1.0 from bullet tO the midbox and then to the tip?

best setup consists of either one midbox or one bullet only, if u need more than one to be satisfied, it simply means the piping is too big in diameter

generally keep at least 30-45" of pipe between extractor and bullet but this is not entirely accurate. need to know engine spec and cam timing to know for sure

This post has been edited by upontheriversky: Oct 13 2011, 12:47 AM

Jul 6 2011, 03:37 AM

Jul 6 2011, 03:37 AM

Quote

Quote

0.0609sec

0.0609sec

0.58

0.58

7 queries

7 queries

GZIP Disabled

GZIP Disabled