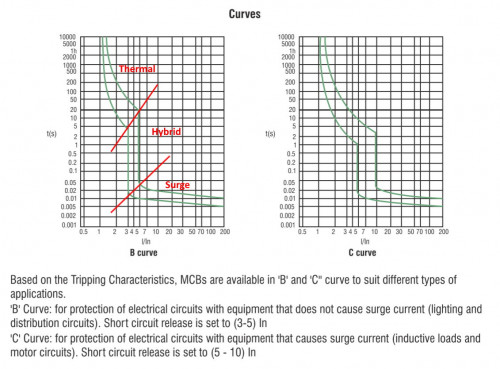

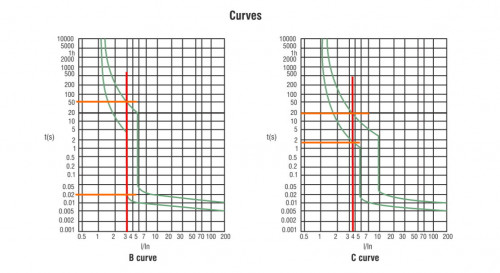

This defines the zones where the tripping occurs, ie, there is one for Thermal (slow) and Surge (fast). The X axis is the current input, and 1x, 2x, 3x, etc of the MCB rating. So a 10A MCB at 1x = 10A, 2x = 20A and so on.

As you can see, surge tripping begins at 3x-5x for B curve, and 5x-10x for C curve.

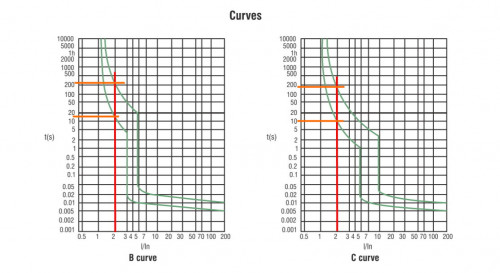

Imagine that your lighting circuit has a B10 (B curve, 10A) MCB. The light shorts out and a current of 20A flows. Thermal tripping will happen, between the time of about 15 to 210 seconds.

If your MCB were a C10, then the thermal trip will happen between 10 and 190 seconds. From the graphs, you can see that the thermal tripping is not significantly different between B and C curve MCBs.

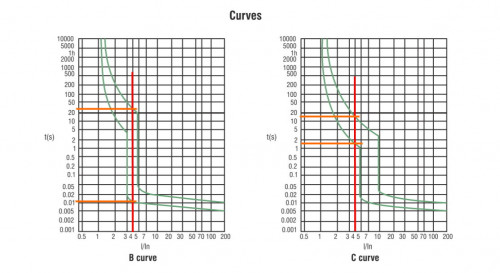

Where there is significantly different is between where the curves start. 3-5 for B curve, and 5 - 10 for C curve. Let's take a 4x short circuit current.

B curve trips between 0.015s to 30s, C curve between 1.5s - 15s

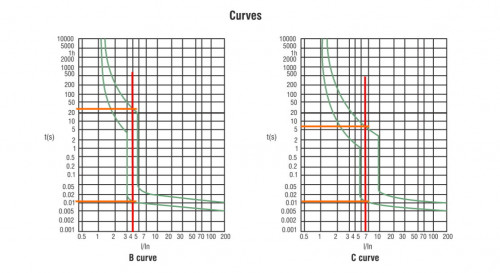

So how do you get past being unable to get B curve MCBs? The answer is you get a lower rated C curve MCB.

Taking the same example above, where the lighting shorts, and 4x (40A) current flows. B10 still trips between 0.015s - 30s, but if you use a C6 MCB (40/6=6.67 aka 40A is 6.67 times the rating of C6) your tripping time drops tremendously.

A B20 MCB at 3x overload (60A) becomes 3.75x if you use a C16 MCB. Not the same, mind you, but more similar to each other. But a B10 at 3x overload, becomes a 5x when using a C6 which brings the exact same timings.

This is actually why the wires you use are extremely important. Wires must be able to withstand the heating of a short circuit, until the MCB thermally trips. As you can see from the top of the Y axis, the value is in the hour range at low overload ~1.1x factor. Always see the Current Carrying Capacity of wires at 70°C (as wires heat up when carrying current) according to the proper standards. And as wires heat up, their CCC decreases. Edit to add : this is why wires are specified big, 4 mm² for water heaters. The wires may be hot, or embedded in concrete with no cooling, or many wires run together causing more heat in the wires. The wire in the water heater will have a more or less known temperature, so 2.5 mm² can be used by the manufacturer for the maximum current at the highest temperature they will reach.

In summary, B curve and C curve are only significantly different at the Surge, or Inrush current when starting inductive devices.

Hope this furthers the discussion. Any mistakes are my own. Please let me know so I may make corrections.

This post has been edited by stormer.lyn: Jan 24 2022, 11:07 PM

Jan 24 2022, 10:59 PM

Jan 24 2022, 10:59 PM

Quote

Quote

0.0374sec

0.0374sec

0.62

0.62

7 queries

7 queries

GZIP Disabled

GZIP Disabled