QUOTE(bluecat68 @ Jun 3 2024, 01:05 PM)

So am I right to think that the forged aluminium pistons will make more noise when cold start and become less noisy after the heat is up because it expand and the gap smaller to the wall ??

By the way from Google it looks like aluminium and aluminium alloys are the main materials in modern engines. So every modern engine suppose to be noisy ??

correct... it will quiet down once its expanded but again im speaking in car applications... not sure about these kapchai brands as i dunno wat they are using.

as for the term "in modern engines"...gotta remember its not limited to the pistons... can mean block, conrod etc etc.

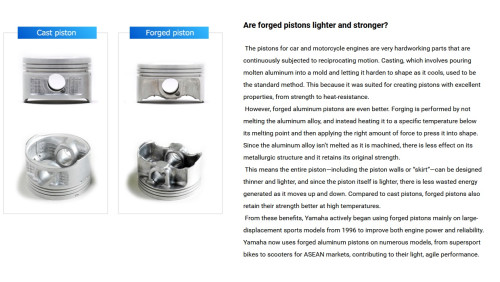

can read here for more indepth about pistons:

https://www.motortrend.com/how-to/impp-1110...tech-knowledge/summary:

» Click to show Spoiler - click again to hide... «

theres basically 3 types of pistons generally used for engines..

1/ cast iron

cast iron are basically stock pistons...the good thing about them is that they dont expand much when heated up and they take very little time to heat up. this allows for tighter piston to wall clearance which basically eliminates piston to wall slap. they are also the weakest type of the 3.

2/ forged with low silicone content using 2618 aluminium

Example of the brand is Wiseco. this type is the strongest of all....the downside is that both types of forged pistons will expand MORE than cast iron pistons so will require greater piston to wall clearance. another downside is that they take longer to heatup and expand. so during cold starts, piston to wall slap is pretty common...at least til the pistons warm up. wall slaps can scratch ur sleeve.

3/ forged with high silicone content using 4032 aluminum

Supertec and CP uses these... a common trait of forged pistons is that they expand MORE than cast iron pistons so will require MORE piston to wall clearance. the bad thing is, they take longer to heat up and expand.. so during cold starts, piston to wall slap is common. again, wall slaps can scratch ur sleeve. this type of piston however, expands less than the one above. so u can get tighter piston to wall clearance and minimize wall slap. they are also not as strong as the one above but still significantly stronger than cast iron pistons.

QUOTE(bluecat68 @ Jun 3 2024, 01:11 PM)

Here another one about aluminium vs cast iron. Looks like aluminium not really that bad comapre to cast iron yeah ??

as u can see in ur screenshot... cast iron has reduced thermal expansion. n this is talking about blocks... ur main concern in the first post is the piston n its piston to wall clearance.

also the block may be made out of aluminium... but ive never seen the cylinder itself made of aluminium... as alu is soft.. all the sleeves ive seen (including aftermarket sleeves designed to handle 1000hp n above) are usually made of steel.

QUOTE(bluecat68 @ Jun 3 2024, 02:01 PM)

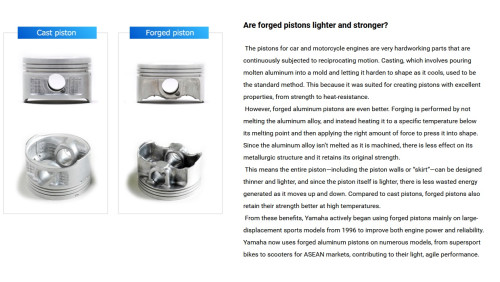

Looks like forged aluminum piston block is what I should looking for.

Source:

https://global.yamaha-motor.com/business/mc...gingPiston.htmly u keep saying block when its talking about the piston? again... forged alu pistons are strong... much stronger than cast iron, but the noise is what ur concerned about. and ive already informed u of the reason for the noise and also the possibility of piston to wall slap. u can read the summary in the spoiler above to get a basic understanding on the type of pistons.

again, block may be alu, but the sleeve is probably gonna be some steel.

Jun 2 2024, 04:23 PM, updated 2y ago

Jun 2 2024, 04:23 PM, updated 2y ago

Quote

Quote

0.0137sec

0.0137sec

0.47

0.47

5 queries

5 queries

GZIP Disabled

GZIP Disabled