QUOTE(bobowyc @ Jan 2 2020, 10:18 AM)

Hi bro, you seem quite well versed in the electrical field. May I ask if you are an electrician? hehe. xD I only know so far about Distribution boards and types of MCB, for lighting, for sockets and AC, heater. But not sure about B16 or B20 MCBs as I have not encountered it before.

Nope not an electrician by profession, but I did sell MCBs, motors, inverters and related automation controls (sensors, PLCs) before many years back.

DB box, matter of affordability for consumer grade units. Best is to go for metal clad boxes (can even find Eaton ones on shopee

), but any decent one will work.

Metal > PVC for flame retardant properties.

Basically the idea is that the MCB is supposed to sacrifice itself way before the wires overheat as that can cause a fire and extensive damage (imagine running new cables need to hack and replace everything). Hence I believe in properly sizing the MCB according to the load i.e. not putting an excessively large MCB for a given load (next size up is best). In my case, my place they put in a C10 (10A) MCB to protect a few lighting points which is rather overkill (even if you use all conventional fluorescent light which has initial spike when starting), it will not overload a C6 or even a 3A MCB. I also need to balance cost/sizing because other than the normal C6/10/16/20 MCBs its hard to get the other sizes affordably in MY.

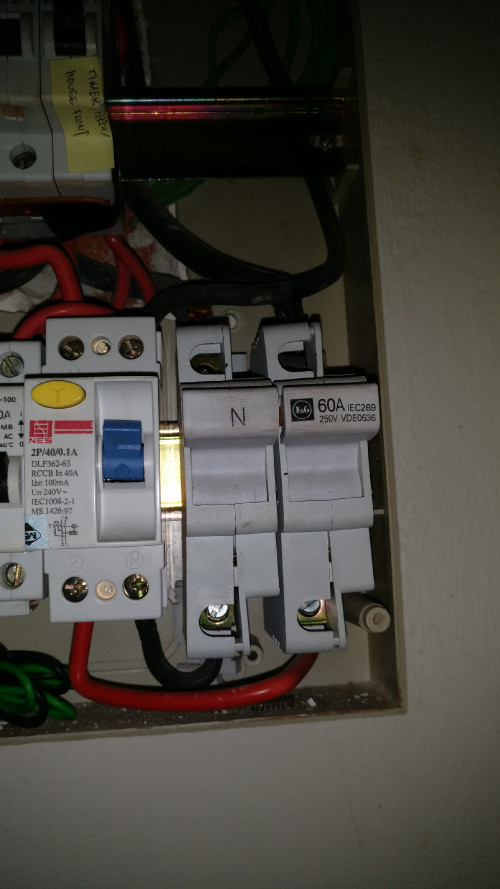

WH (water heater) has ST special guidelines issued that you must protect areas with wet floor with 10ma RCCD - this will protect current imbalance only (i.e. input L and return output N must equal current else something has leaked (better get decent ones from ABB/Hager/Schneider).

Note that RCCD only protect against imbalanced current only, it does NOT protect against current overload (wire protection).

Hence WH RCCD must be run together with a normal MCB (for current overload).

Why B curve instead of C curve for WH?As WH's heater is a resistive load (i.e. uses resistive metal to generate heat) and not inductive (ie. no motor is involved) load, B curve MCB is better as they are more sensitive (trips at lower spike current) than a C curve MCB (which is essentially a general use one as things like aircon/vacuum cleaner are motor-based, so less nuisance tripping).

RS/element14 does sell Siemens B16 MCB

Siemens B16 MCB which should work for most 3.3/3.6kw heater (3300/240=13.75A, mine ran at 13.2A on clamp meter test) (3600/240 = 15A which is cutting it a bit close but still possible to use on 16A MCB). If you have very strong water pressure and using those 4.8kw models from hitachi you are running 20A nominal so a 20A would not be enough, probably a B25/C25 can be used (https://new.abb.com/products/2CDS211001R0254/miniature-circuit-breaker-sh200-1p-c-25-ampere).

https://cache.industry.siemens.com/dl/files...50852395217.pdfsee page 23. actually siemens recommends using B curve for universal use (socket outlets and lighting circuits) vs MY general practice to use C curve for everything

https://www.se.com/au/en/faqs/FA290880/

https://www.se.com/au/en/faqs/FA290880/even SE also recommends B curve for residential use.

What is B- or C- curvehttps://www.se.com/in/en/faqs/FA228794/ and

https://library.e.abb.com/public/e39a8392ab...403003B0202.pdfsee page 7 trip curve info for diff between B/C/D curve

https://library.e.abb.com/public/114371fcc8...2D0201_view.pdfsee page 3, trip curve characteristics for inrush (spike) current. this means B spike is 3-5x rated current before tripping, C spike is 5-10x rated current before tripping.

This post has been edited by ceo684: Jan 2 2020, 01:58 PM

Dec 31 2019, 12:29 AM, updated 6y ago

Dec 31 2019, 12:29 AM, updated 6y ago

Quote

Quote

0.0197sec

0.0197sec

0.76

0.76

5 queries

5 queries

GZIP Disabled

GZIP Disabled