The intro

So...i salvaged an old fridge, it originated from my dad's restaurant where the fridge was rusted quite seriously. one day it starts tripping the power, due to the old age of the fridge he decided not to call the technician instead

I requested those guys from the fridge repairing shop to send that old fridge to my house while they bring in the new fridge. By the way that old crap was a domestic fridge, i din took a pic of it as i the chances of breaking one of those old copper tubings. It even lost its wiring diagram, great...now i gotta find out which is which by testing it manually.

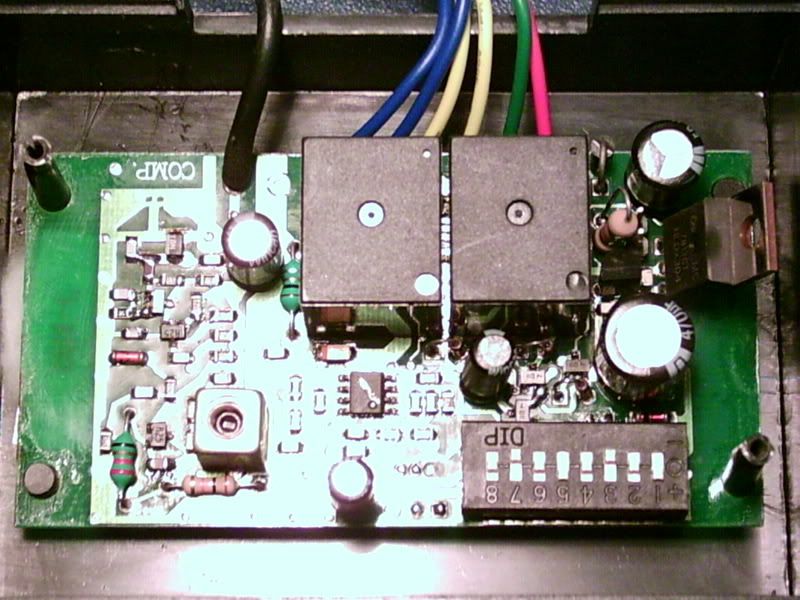

Found out that the defrosting timer was the culprit, wired things up directly to the mains...moment of truth........"zeeenng"....the compressor shook a lil....OMG...its still working.

Went to the front, strip of the alu cover plate.....the cooling coil was giving a fog effect like those cryo tanks but way less in size and volume

Thats when my imagination flew sky high

Heres what i've done so far,

stripped the cooling system out, easy?? no, the catch is strip it off its casing or wateva u call it without puncturing the tubes

(Theres a 3 star rating on the fridge door, dunno wth izit though)

Attach it upright to my window's iron rods(hot side outside my room)

Cut some corners of the glass for the cooling coil's tubing with a glass cutter

Made a box out of polystyrene to house the cooling coil

Fixed pipes to the box

Installed a centrifugal aka blower fan(picked up for RM40 from a car AC technician from his pile of AC junks)

Heres the completed poly box, insulated the copper tubes with nitrile foam tube, 80mm pvc pipe attached along with the blower fan.

Tht fan is really strong at full force...i have difficulty opening my eyes when direct to my face during testing.

(this is a stupid way to test a blower, it could pick up a lose screw or rock or should the blades give up and shatter. it would launch it straight to my face)

During the cleaning, i noticed the carbon brushes are almost worn out. Got myself a pair of new carbon brush for RM10

For those who want to get replacement brushes

They have most shapes and sizes, else fails, they can reshape/resize one to the exact match on the spot, Soldering service provided too.

Great Eastern Carbon, located at jln loke yew. Next to the cemetary. If u live outside kl, u can PM me

I notice someone's Dremel is dead due to a worn out carbon brush

3 speed fan controller, off..slow...medium...full.

The 80mm pipe was cut offed at the top and siliconed to the base of the poly box, i did this to duplicate as much as possible to the way it cools in the fridge, drawing air at the bottom while a fan is at the top sucking. Manufacturer have reasons of doing so...so its best to keep it the way it was

The piping....top cold air, bottom hot air. Class O 80MM PVC pipe, RM28/piece so far used up oni 1, gonna need 30ft more

Its cheaper to buy one whole piece than buying seperate. I wonder how low can i bring the air temp before the pipe starts condensing lots of water. Sry bout the cacings, not tied up yet

The entire rig is gonna be covered up in poly as well to keep the room's heat out and prevent condensation. Im planning to lay a layer of alu foil on the inside of the poly to create a farraday cage and to prevent statics, i think the poly is pretty good at getting static build up.

But i'll not cool it past dewpoint, the coldest i'll planned to go its 8'C cause HDD min temp is 5'C.

PSU is gonna be excluded from the luxury of air-cond cooling

ROMs, yes. a large block of poly will be attached to the tray. it'll be shaped to taper in from outside in with matching shape on the faceplate to limit thermal exchange, moisture and cold air flowing out.

The cold air its gonna come in in between the psu and router

As far as i reached now, the exhaust or suction hole, a pipe will be attached to the bottom. The hole was made by drilling a ring of holes and a gentle nudging with a chipper. reason it was made this way was to make the sharp pin like ends so that when i push the pipe in, it'll grip the pipe, pulling it back out will just make the pins dig deeper into the pipe. it'll save a lot of work to attach the pipe to the casing, just push in, and it'll stay there.

Your helpful comments are needed as i might be heading for some mistakes i yet to know. Such as galvanic corrosion i din thought of, the cooling coils has some plastic wrapper around the copper, while fins are alu, the copper will sooner or later corrode the fins, counter measures taken though

This post has been edited by radioactive: Jul 23 2007, 01:50 AM

Jul 6 2007, 05:10 AM, updated 19y ago

Jul 6 2007, 05:10 AM, updated 19y ago

Quote

Quote

0.0226sec

0.0226sec

0.62

0.62

5 queries

5 queries

GZIP Disabled

GZIP Disabled