manufacturers around the world promote Ultra high tensile steel

this one promote HPF pulak.. lol means to say they not using Ultra high tensile steel to begin with!

![]() Proton Persona terlalu keras, Bomba susah potong

Proton Persona terlalu keras, Bomba susah potong

![]() Proton Persona terlalu keras, Bomba susah potong

Proton Persona terlalu keras, Bomba susah potong

|

|

Aug 22 2016, 05:49 PM Aug 22 2016, 05:49 PM

Return to original view | Post

#1

|

Senior Member

9,206 posts Joined: Jun 2006 |

manufacturers around the world promote Ultra high tensile steel

this one promote HPF pulak.. lol means to say they not using Ultra high tensile steel to begin with! |

|

|

Aug 22 2016, 05:52 PM Aug 22 2016, 05:52 PM

Return to original view | Post

#2

|

Senior Member

9,206 posts Joined: Jun 2006 |

|

|

|

Aug 22 2016, 06:07 PM Aug 22 2016, 06:07 PM

Return to original view | Post

#3

|

Senior Member

9,206 posts Joined: Jun 2006 |

|

|

|

Aug 22 2016, 06:18 PM Aug 22 2016, 06:18 PM

Return to original view | Post

#4

|

Senior Member

9,206 posts Joined: Jun 2006 |

QUOTE(dares @ Aug 22 2016, 06:10 PM) as far as I know only Mazda using 1.8GPa steel on their CX5. and only on the front reinforcement beam. and u saying whole car chassis was formed with HPF meh? am sure is only few critical components only la.isnt the final figure the most important? regardless of the strength before treatment? i think if start from high figure steel stocks is better and consistent overall strength for the part. |

|

|

Aug 22 2016, 06:48 PM Aug 22 2016, 06:48 PM

Return to original view | Post

#5

|

Senior Member

9,206 posts Joined: Jun 2006 |

|

|

|

Aug 22 2016, 06:57 PM Aug 22 2016, 06:57 PM

Return to original view | Post

#6

|

Senior Member

9,206 posts Joined: Jun 2006 |

|

|

|

Aug 22 2016, 07:00 PM Aug 22 2016, 07:00 PM

Return to original view | Post

#7

|

Senior Member

9,206 posts Joined: Jun 2006 |

|

|

|

Aug 22 2016, 07:10 PM Aug 22 2016, 07:10 PM

Return to original view | Post

#8

|

Senior Member

9,206 posts Joined: Jun 2006 |

|

|

|

Aug 23 2016, 12:10 AM Aug 23 2016, 12:10 AM

Return to original view | Post

#9

|

Senior Member

9,206 posts Joined: Jun 2006 |

QUOTE(Yottabyte @ Aug 22 2016, 08:37 PM) if proton could gain 5 stars with 'only' HPF, why need for more supposedly expensive steel? looks like proton engineers are so pro they managed to cut cost with l337 technique. since when did they manage to cut cost with each car they build? if they did . they wont lose 1.6bil building 100k cars right? i.e. 16k per car in losses. |

|

|

Aug 23 2016, 07:06 PM Aug 23 2016, 07:06 PM

Return to original view | Post

#10

|

Senior Member

9,206 posts Joined: Jun 2006 |

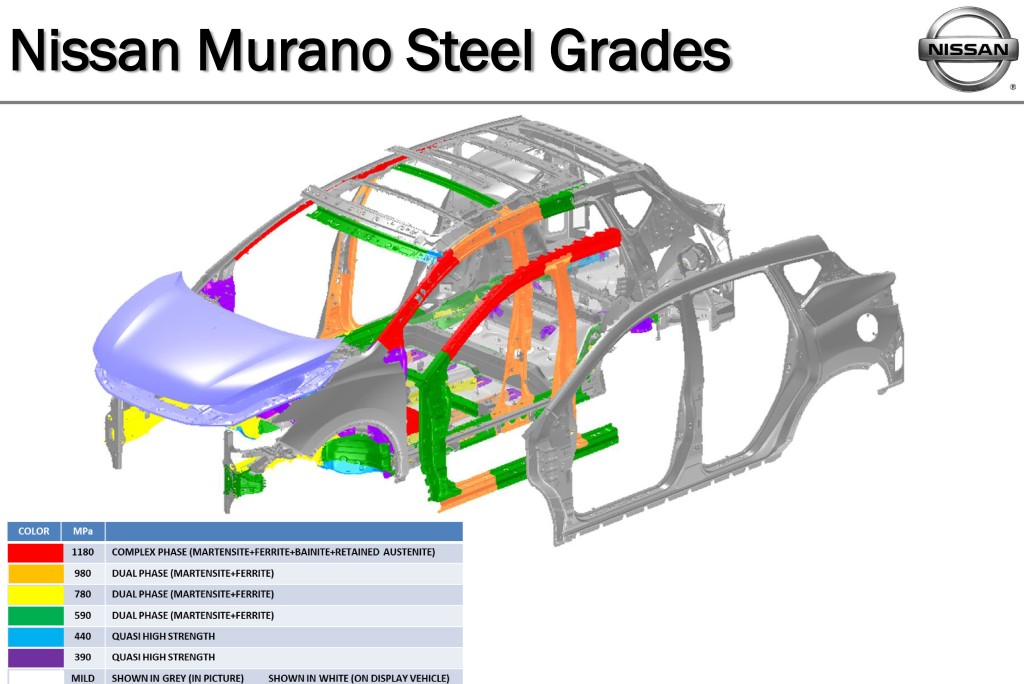

QUOTE(xxhunter @ Aug 23 2016, 05:24 PM) my god its not about the strength of the material only la dear cavemans, its all in the whole structured design. And for ancap different segment cars should not be compared directly haizz. deswai i dunno why HPF , which is a steel forming technology suddenly end up as a factor to promote safety lol.just say you got use a few metal parts which achieve ultra high tensile strength la. and show 3d chassis diagram on those colored parts example below. no one cares if its HPF or other ways to achieve the strength.  |

|

|

Aug 23 2016, 11:47 PM Aug 23 2016, 11:47 PM

Return to original view | Post

#11

|

Senior Member

9,206 posts Joined: Jun 2006 |

QUOTE(axelrade @ Aug 23 2016, 11:41 PM) do you realise Ultra High Strength Steel start from 700MPa onward. This HPF is actually >1500Mpa and in ultra high tensile strength steel category. HPF is process la processAlso proton has been using this part since Preve, and the development project start from 2010. its not the product. |

|

|

Aug 24 2016, 12:11 AM Aug 24 2016, 12:11 AM

Return to original view | Post

#12

|

Senior Member

9,206 posts Joined: Jun 2006 |

QUOTE(fantasy1989 @ Aug 24 2016, 12:08 AM) just asking 1 question ..what is the minimum MPA to be categorized under ultra high tensile steel category? maybe as someone above says maybe from 700..all the way to 2000i am not steel guy .. so just bare with my newbie question can use any process that is required to handle it. at the end still state as what strength steel.(product) not HPF ke cold rolled ke..(process) |

|

|

Aug 24 2016, 12:26 AM Aug 24 2016, 12:26 AM

Return to original view | Post

#13

|

Senior Member

9,206 posts Joined: Jun 2006 |

QUOTE(axelrade @ Aug 24 2016, 12:13 AM) I know HPF is process which is hot press forming. But the term HPF steel normally being use to identify this type of steel. NOPEfor sharing [attachmentid=7374125] comes in rolls and sheets also above 1000MPa (not even hot pressed yet) some steel suppliers data sheet below. pic added  This post has been edited by ar188: Aug 24 2016, 12:27 AM Attached thumbnail(s)

|

|

|

Aug 24 2016, 01:38 AM Aug 24 2016, 01:38 AM

Return to original view | Post

#14

|

Senior Member

9,206 posts Joined: Jun 2006 |

QUOTE(axelrade @ Aug 24 2016, 01:03 AM) Ok let me summarize a bit, the 1500MPa is HPF part produce from HPF steel (initial around 600MPa with special coating) by using HPF method. you forgot, that spring back issue that u describe can be attributed due to low elongation is properties (see chart) generally for ultra high strength steels, this as u said affecting formability of the stamp parts.Correct, the one you listed is UTHSS, but it is impossible to stamp this cold rolled steel because the tensile strength is to much. It will create spring back effect to the part. That is why HPF method being use to counter this spring back issue. You need to understand the different between HPF steel and normal cold rolled steel. HPF steel have special coating to transform the steel from 600Mpa to 1500Mpa through HPF process. While UTHSS cold rolled produce through normal cold rolling process. another info for sharing. [attachmentid=7374446] now got new products that can settle the elongation issue. advance steel products its now in 3rd generation and newer already.  another point, is that the use of high strength steels is so that you use less steel in weight to maintain strength (while meeting highest crash test results) while reducing BIW (body in white) weight, thus improving fuel economy did proton ever promote that aspect of why top 10 manufacturers use UHSS to save weight thus improve fuel economy? maybe that is what they should be doing to highlight such benefits to lay people who dont know and dont care what HPF is. This post has been edited by ar188: Aug 24 2016, 01:39 AM |

|

|

Aug 24 2016, 12:25 PM Aug 24 2016, 12:25 PM

Return to original view | Post

#15

|

Senior Member

9,206 posts Joined: Jun 2006 |

|

| Bump Topic Add ReplyOptions New Topic |

| Change to: |  0.0244sec 0.0244sec

0.53 0.53

7 queries 7 queries

GZIP Disabled GZIP Disabled

Time is now: 15th December 2025 - 07:35 AM |