Its been sometime since ive written anything coz ive been rather busy with work and trolling the forums. Before i go on there are a few pointers to the purpose of this write up,

1. this is all about the cost of producing the said guitar it has nothing to do with tone. Higher cost of production doesn’t mean its a better guitar, it just means that the guitar is more expensive to make.

2. The aim is to naturally point out what you are generally buying for in an expensive guitar, it doesn’t try to guide you waht IS a good guitar that is in another article

3. Note the rule of diminishing returns, the higher the cost the less “gains” you tend to have. Therein, how you want to go about understanding what to buy for yourself depends on you.

4. Most if not all the information here is taken from forums, youtube videos and questions to other otais. They are not the rule, if you do see something to correct feel free to highlight and i will change it

Lets proceed:

I would like to divide guitar making into 2 eras for easier understanding: the handmade era and the CNC era. what is a CNC you might ask?

This:

its basically a programmed machine...lol

The handmade era pretty much explains itself, traditionally guitar shapes are cut by carpenters tools (a Bandsaw) from a piece of wood. Thereafter its sanded and detailed to look more like a beautiful piece of music instrument. Along the years however this becomes confusing, many guitar companies claim that their guitars are handmade. Then you hear someone somewhere say its CNC and argument ensures. I will explain this marketing ploy later and which its kinda misleading on both sides of the coin.

At one point in time, i suspect the 70-80s CNC went into the mainstream, this meant that many guitar companies started adopting them. CNC is important in our discussion not for its workmanship but for its time factor.

See traditionally bandsawing a guitar is tedious and inaccurate; CNC makes this fast and more consistent. What this means is labour cost goes down! Basically you can shut down the whole ”bandsaw & routing” department and use just a couple of engineers to run the whole process flow. In an hour, a traditional maker might only produce 2 rough cut bodies, now maybe you can make 10.

Where this becomes confusing is in the term “handmake” and the utilization of the CNC, let me take 2 extremes to make a point.

Fender Standard Tele, simple body design which can be cut easily by the CNC very little additional workmanship is required. Basically a shaped plank with pups.

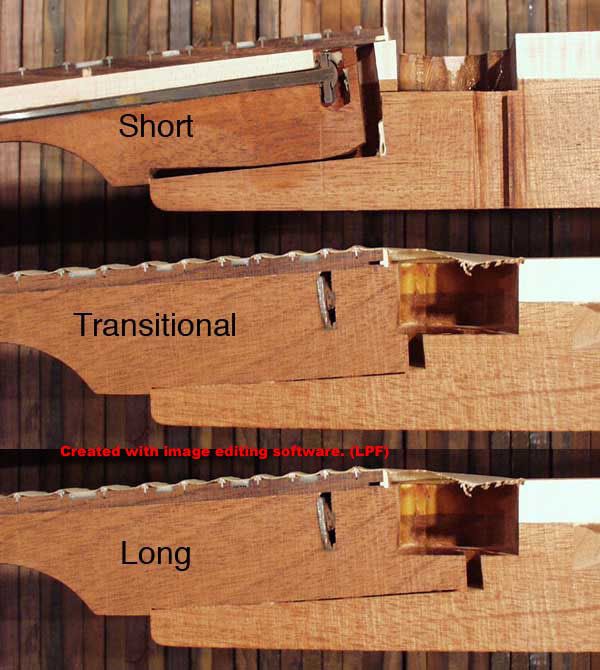

Gibson Les Paul standard, arched top, single cut design which is also cut by CNC HOWEVER the arched top requires more accurate CNC and more post CNC sanding and finishing work. Gibson LP standard also features binding, of which is still by hand.

Notice the difference? They are both CNC, but Gibson has more traditional handmake qualities due to the arched top and binding. Where the guitar companies “claim” their handmake status is in this, they do rough cuts then sand it down and apply the details. Hence are your guitars handmade? Not really. But are they machine made? Not really also.

If you cant picture what im saying here is a factory tour video...

i would suggest going through the whole tour, it gives a lot of information on how a PRS is made

This post has been edited by +3kk!: Jun 24 2013, 12:37 PM

Jun 24 2013, 09:37 AM, updated 13y ago

Jun 24 2013, 09:37 AM, updated 13y ago

Quote

Quote

0.0272sec

0.0272sec

0.33

0.33

5 queries

5 queries

GZIP Disabled

GZIP Disabled