As I mentioned, I felt that the Y Corners that came with my kit felt a bit weird, so I decided to print a set of my own using my UP Mini.

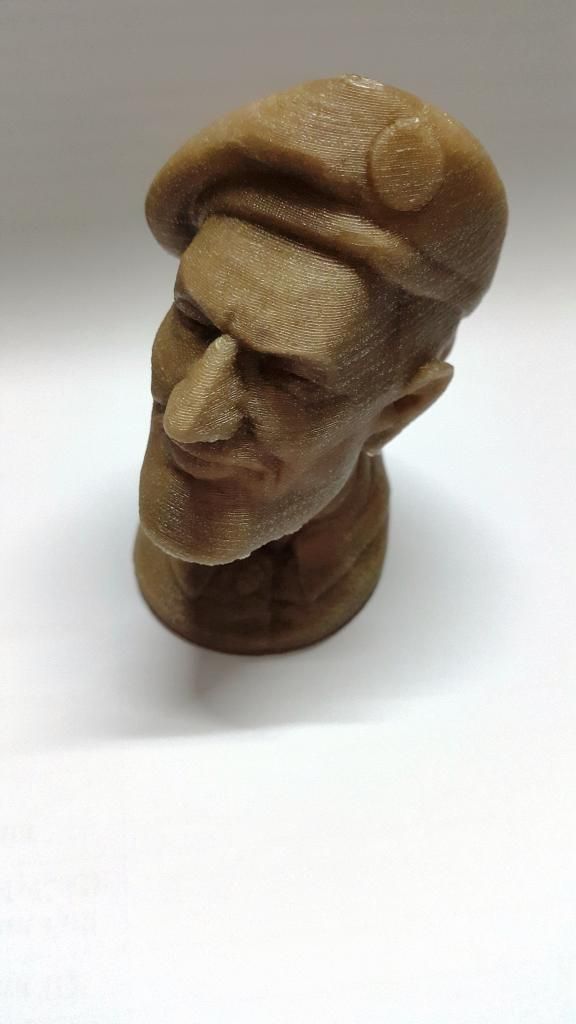

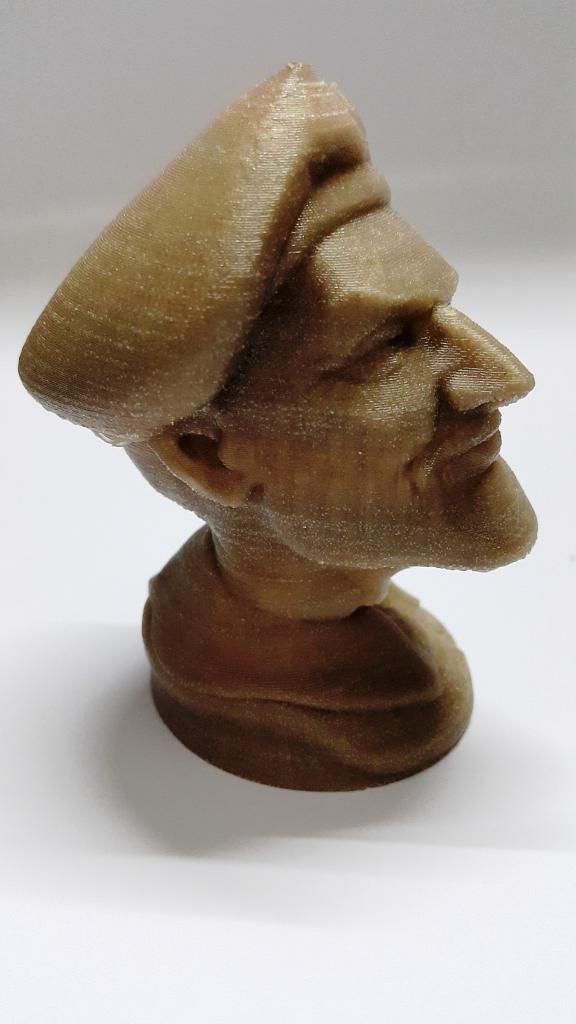

As I expected, the base lifted because it was a long wide base containing the four pillars. so I'm pretty sure the measurements are slightly out on my piece, but check out the comparison between the two pieces.

You can see the bigger image here :-

http://1drv.ms/1xL7uIhThe one I printed is on the left, the one I bought is on the right.

It should be pretty obvious that the one I bought doesn't look very good, the layers are jagged and uneven compared to the smoother even layers which I printed.

What my question here is that if the person could have printed his part at a better quality, why didn't he? After all, he's selling these anyway.

The other question is the obvious is this the best a RepRap can do?

There are a few answers to this. like @altan has mentioned previously, the guy could be inexperience at doing this and done this less than perfectly.

I'm posting this not to deter people from RepRaps, this is for everyone's knowledge about what's available out there.

One of the main reasons I bought the RepRap is for knowledge and experimentation, the UP! printers are very rigid and inflexible and also my UP! Mini is flawed by default. So it all depends on what exactly you want to do with it.

I will defiantly have further opinions once I actually finished and used the Reprap myself, but this is just food for thought currently. I'm sure those of you who already have RepRaps can chime in on this.

Nov 14 2014, 09:05 AM

Nov 14 2014, 09:05 AM

Quote

Quote

0.0239sec

0.0239sec

0.76

0.76

6 queries

6 queries

GZIP Disabled

GZIP Disabled