anything else beside facebook? i didnt use facebook, their didnt has any account here?

Repraps and DIY 3D Printing!, Open source hardware~

Repraps and DIY 3D Printing!, Open source hardware~

|

|

Feb 21 2015, 03:26 PM Feb 21 2015, 03:26 PM

|

Newbie

0 posts Joined: Feb 2015 |

anything else beside facebook? i didnt use facebook, their didnt has any account here?

|

|

|

|

|

|

Feb 21 2015, 03:36 PM Feb 21 2015, 03:36 PM

|

Junior Member

188 posts Joined: Sep 2009 From: Either PJ, JB or SG but not at your house! |

|

|

|

Feb 21 2015, 03:43 PM Feb 21 2015, 03:43 PM

|

Junior Member

117 posts Joined: Feb 2011 From: Old Klang Road |

QUOTE(Prosperer @ Feb 21 2015, 03:26 PM) They have, but not active here since Nov, 2014...https://forum.lowyat.net/topic/3113988/all |

|

|

Feb 21 2015, 07:28 PM Feb 21 2015, 07:28 PM

|

Junior Member

356 posts Joined: Jun 2006 |

Hi guys,

I have this issue with my printer stopping halfway during a printing session. I suspect that it has something to do with the current in my house. Is there anyway i can resume the printing after that? Thanks in advance. |

|

|

Feb 21 2015, 11:21 PM Feb 21 2015, 11:21 PM

|

Junior Member

188 posts Joined: Sep 2009 From: Either PJ, JB or SG but not at your house! |

QUOTE(eehtsitna @ Feb 21 2015, 07:28 PM) Hi guys, Its not possible to resume a print that fail halfway unless you know how to manipulate the gcode of the file.I have this issue with my printer stopping halfway during a printing session. I suspect that it has something to do with the current in my house. Is there anyway i can resume the printing after that? Thanks in advance. I have problems like this before and it depends on a few factors. You might want to check your power supply and the cable.connecting to the printer, I had a problem once where the power supply shorted internally and had to open the sealed laptop case to fix the problem. Another is to see if any of the power supply wire is melting. I had a power supply wire barrel plug melted a little and the wires inside was slightly burnt. Another issue is due to the usb communication, make sure to use a cable as short as possible to avoid any data loss. USB supplies 5 volts so their voltage drop a tremendously over long distance. A 1 meter cable will have more data loss than a 10 cm cable. Also winding a long cable around a ferrite core helps in reducing noise. Also, if you think your house have electrical issues, you might want to invest in a uninterruptable power supply, UPS unit. At least the backup battery will sort out any micro power interruptions and also keep your printed running during a black out. |

|

|

Feb 22 2015, 03:15 PM Feb 22 2015, 03:15 PM

|

Junior Member

292 posts Joined: Jan 2003 |

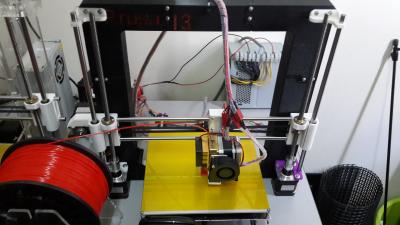

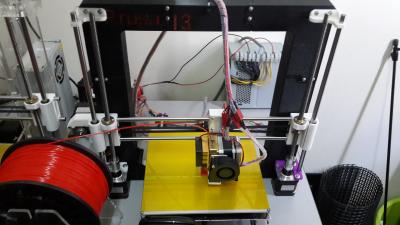

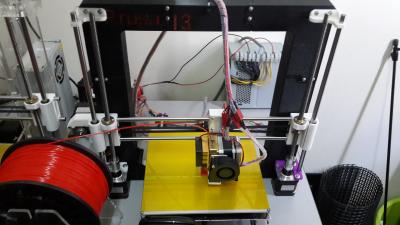

2nd Prusa i3 up and running, this time using ramps 1.4 and 400w PSU. I did abit of power measurements, the hotend pulled about 3 amps and the heatbed about 7.

Also noticed that the PSU couldnt regulate the 12v properly, after a while it dipped to about 11.5. Must be one of em cheap PSU's

Made a custom holder for the ramps,fan and mosfet heatsink, moved the mosfets onto a heatsink.

This post has been edited by KLKS: Feb 22 2015, 03:19 PM |

|

|

|

|

|

Feb 22 2015, 03:36 PM Feb 22 2015, 03:36 PM

|

Newbie

0 posts Joined: Feb 2015 |

QUOTE(KLKS @ Feb 22 2015, 03:15 PM) 2nd Prusa i3 up and running, this time using ramps 1.4 and 400w PSU. I did abit of power measurements, the hotend pulled about 3 amps and the heatbed about 7. Hey man,Also noticed that the PSU couldnt regulate the 12v properly, after a while it dipped to about 11.5. Must be one of em cheap PSU's

Made a custom holder for the ramps,fan and mosfet heatsink, moved the mosfets onto a heatsink.

Where did you buy the kit?? Or did you assemble things yourself? I plan on buying a kit I want to get most of things locally. |

|

|

Feb 22 2015, 03:43 PM Feb 22 2015, 03:43 PM

|

Junior Member

292 posts Joined: Jan 2003 |

QUOTE(ishe7ata @ Feb 22 2015, 03:36 PM) Hey man, My first i3 was a kit (from aliexpress), 2nd i3 (the one pictured above) is assembled from parts, 90% of which is from aliexpress. Things which i bought locally were the smooth rods, afew bearings, and screws and bolts.Where did you buy the kit?? Or did you assemble things yourself? I plan on buying a kit I want to get most of things locally. |

|

|

Feb 22 2015, 03:57 PM Feb 22 2015, 03:57 PM

|

Junior Member

188 posts Joined: Sep 2009 From: Either PJ, JB or SG but not at your house! |

QUOTE(KLKS @ Feb 22 2015, 03:15 PM) 2nd Prusa i3 up and running, this time using ramps 1.4 and 400w PSU. I did abit of power measurements, the hotend pulled about 3 amps and the heatbed about 7. Nice wiring job there for the MOSFETAlso noticed that the PSU couldnt regulate the 12v properly, after a while it dipped to about 11.5. Must be one of em cheap PSU's

Made a custom holder for the ramps,fan and mosfet heatsink, moved the mosfets onto a heatsink.

|

|

|

Feb 22 2015, 08:33 PM Feb 22 2015, 08:33 PM

|

Newbie

0 posts Joined: Feb 2015 |

QUOTE(KLKS @ Feb 22 2015, 03:43 PM) My first i3 was a kit (from aliexpress), 2nd i3 (the one pictured above) is assembled from parts, 90% of which is from aliexpress. Things which i bought locally were the smooth rods, afew bearings, and screws and bolts. Hey can you post the ones you purchased? I mean the specific link? I'm making a purchase soonDid you have to pay any import taxes? |

|

|

Feb 22 2015, 09:12 PM Feb 22 2015, 09:12 PM

|

Junior Member

292 posts Joined: Jan 2003 |

This is the store i bought from on aliexpress

http://www.aliexpress.com/store/319147 Paid about 440USD shipped incl 2 rolls of fillament, was lucky didn't kena tax. This post has been edited by KLKS: Feb 22 2015, 09:16 PM |

|

|

Feb 22 2015, 09:19 PM Feb 22 2015, 09:19 PM

|

Junior Member

292 posts Joined: Jan 2003 |

I just chanced upon this while browsing aliexpress, looks pretty good

http://www.aliexpress.com/store/product/Ho...2026704108.html |

|

|

Feb 23 2015, 02:11 AM Feb 23 2015, 02:11 AM

|

Junior Member

188 posts Joined: Sep 2009 From: Either PJ, JB or SG but not at your house! |

QUOTE(KLKS @ Feb 22 2015, 09:12 PM) This is the store i bought from on aliexpress USD 440? You must have been "really" lucky because normally that amount would be held at customs for tax.http://www.aliexpress.com/store/319147 Paid about 440USD shipped incl 2 rolls of fillament, was lucky didn't kena tax. |

|

|

|

|

|

Feb 23 2015, 10:49 AM Feb 23 2015, 10:49 AM

|

Newbie

1 posts Joined: Oct 2005 |

Hi All,

Firstly Happy Chinese New Year to all.... Been printing many calibration cubes over the last couple of weekends and when perfectly. Got a bit ambitious over the last weekend and started printing some larger prints. All is well until about 1.5 hours into the print, the extruder got jammed. Still patient, I clean up the hotend, and started printing again. This time it lasted a bit longer, a bit less than 2 hours. Unfortunately, it jammed again at 90% of the print. Clean and tried again, with same problem. Anyone have any idea why it only jam up after printing for more than 1.5 hours? Print quality before jam looks good.... I am printing with PLA, at ard 185C, heated bed at 60C. Using a J-Head with fan. Symptoms starts with the extruded PLA becomes thinner, then starts to comes out in droplets every few mm, then the droplets get further apart then it just jams. I am clueless now.. Any suggestion on what to tweak or change... Jonathan |

|

|

Feb 23 2015, 10:58 AM Feb 23 2015, 10:58 AM

|

Junior Member

292 posts Joined: Jan 2003 |

Have you tried printing at 190-195, i've had to up the temp of some PLA prints to 210 just so there's layer adhesion. Sometimes it can be a clogged nozzle because of poor quality fillament. Maybe post some pictures?

|

|

|

Feb 23 2015, 11:46 AM Feb 23 2015, 11:46 AM

|

Junior Member

188 posts Joined: Sep 2009 From: Either PJ, JB or SG but not at your house! |

QUOTE(jamminc @ Feb 23 2015, 10:49 AM) Hi All, Hello, Happy CNY, and welcome to the Reprap discussion where we double as your technical support and triple as a place to source for 3D printing parts. Basically we generally discussion on all things Reprap and 3D printers here. Firstly Happy Chinese New Year to all.... Been printing many calibration cubes over the last couple of weekends and when perfectly. Got a bit ambitious over the last weekend and started printing some larger prints. All is well until about 1.5 hours into the print, the extruder got jammed. Still patient, I clean up the hotend, and started printing again. This time it lasted a bit longer, a bit less than 2 hours. Unfortunately, it jammed again at 90% of the print. Clean and tried again, with same problem. Anyone have any idea why it only jam up after printing for more than 1.5 hours? Print quality before jam looks good.... I am printing with PLA, at ard 185C, heated bed at 60C. Using a J-Head with fan. Symptoms starts with the extruded PLA becomes thinner, then starts to comes out in droplets every few mm, then the droplets get further apart then it just jams. I am clueless now.. Any suggestion on what to tweak or change... Jonathan Looks like your problem stem from poor filament quality as KLKS has mentioned but at the same time, your PLA printing temperature is a bit too low. You may want to clean out your nozzle once again and try the print at a much higher temp print of 195 - 205 Deg C. If you have a caliper, you can measure the filament diameter for variation. Normally I take 3 to 5 points and about 1 meter apart and see if there are any points that went off more than 1.8 mm. The best is if the filament can stay within +- 0.05 mm and the filament average should be at most 1.75 mm. Also visual inspection of the filament will help in spotting sand and grime in the filament. I think DarkTenno had that problem before when he bought a spool of filament form ebay that has sand particles in the filament. Also, nozzle cleaning technique is also important. I normally heat my nozzle up to 220 Deg C and shut of the power before dismantling the nozzle from the hotend. Doing this will make the nozzle easier to remove because the melted PLA inside the hotend doesn't jam up during removal of the nozzle. Depending on the type of hotend you use, you can separate the heat break from the heating block and nozzle. The best way I found for cleaning nozzles is to use a blow torch and just burn out all the PLA and the PLA black residue out until the nozzle looks clean. Try not to heat an aluminium nozzle for too long since it melts at about 600 Deg C which is too low for a blow torch burning at twice the temp or 1200 Deg C. Brass nozzles are more resilient during cleaning with a blow torch so it can be heated way longer. Another way is to use solvents but I find it too slow, smelly and is time consuming. After that, if you have a micro drill bit set, use the appropriate size for your nozzle and clean out the nozzle hole with the bit. Next check the teflon/PTFE sleeve (some hotends may not have teflon sleeving) in the heat break and clean out PLA with a hot air gun. Do not use anything hotter than 260 Deg C to heat the teflon sleeve as it will melt and deform the sleeve. Then clean out any bits of PLA stuck in the hot ends threads so it will be easier to assemble the hotend back. After cleaning, just run the hotend at 195 to 205 deg C and push a filament through. It should go through smoothly. I would suggest you not use the filament for long periods of print but for small prints and buy better quality filaments for longer runs. Hope this helps. |

|

|

Feb 23 2015, 12:22 PM Feb 23 2015, 12:22 PM

|

Junior Member

347 posts Joined: Feb 2005 From: KL |

QUOTE(altan @ Feb 23 2015, 11:46 AM) If you have a caliper, you can measure the filament diameter for variation. Normally I take 3 to 5 points and about 1 meter apart and see if there are any points that went off more than 1.8 mm. The best is if the filament can stay within +- 0.05 mm and the filament average should be at most 1.75 mm. Also visual inspection of the filament will help in spotting sand and grime in the filament. I think DarkTenno had that problem before when he bought a spool of filament form ebay that has sand particles in the filament. Yeap, but it not sand but metal http://mylinux.net.my/blog/2014/06/30/chea...om-china-again/ I print my PLA at 185 but each pla have different tempeture, you need to experiment with the temp setting to get it right, altan the hotend you selling nozzle are not exchangeable? my geeetech hotend is a waste of money, need a new hotend for my kossel |

|

|

Feb 23 2015, 12:33 PM Feb 23 2015, 12:33 PM

|

Junior Member

188 posts Joined: Sep 2009 From: Either PJ, JB or SG but not at your house! |

QUOTE(DarkTenno @ Feb 23 2015, 12:22 PM) Yeap, but it not sand but metal I don't mind doing an exchange but it depends on the hotend condition you want to exchange. What problems is your geeetech hotend having and what was the last filament material used?http://mylinux.net.my/blog/2014/06/30/chea...om-china-again/ I print my PLA at 185 but each pla have different tempeture, you need to experiment with the temp setting to get it right, altan the hotend you selling nozzle are not exchangeable? my geeetech hotend is a waste of money, need a new hotend for my kossel |

|

|

Feb 23 2015, 12:47 PM Feb 23 2015, 12:47 PM

|

Junior Member

347 posts Joined: Feb 2005 From: KL |

QUOTE(altan @ Feb 23 2015, 12:33 PM) I don't mind doing an exchange but it depends on the hotend condition you want to exchange. What problems is your geeetech hotend having and what was the last filament material used? the hot end fail on bench test it a brand new all metal hotend with 0.3 nozzle, I think it can be fixed by changing the heater block with a proper design, like those Mk7 heater block like this one, http://www.aliexpress.com/item/5pcs-lot-Ma...1887070373.html but since it still CNY ordering some from ebay will take forever to ship - nozzle and cold end have 1 grub screw to hold them but! it so close to melt chamber plastic leaked out of the grub screw hole! - heater cartridge seem ok but heat not spread evenly on the heater block, temp measured on cartridge are 240 but the heater block only measured 190 - thermistor location near heating cartridge it report correct temp, but when as point no 2, heater block temp have lower temp than it actual temp set on RAMPS Note: temp measured using IR thermometer and a digital multimeter This post has been edited by DarkTenno: Feb 23 2015, 12:50 PM |

|

|

Feb 23 2015, 12:59 PM Feb 23 2015, 12:59 PM

|

Junior Member

188 posts Joined: Sep 2009 From: Either PJ, JB or SG but not at your house! |

QUOTE(DarkTenno @ Feb 23 2015, 12:47 PM) the hot end fail on bench test If you like I can meet up for the exchange, I currently have a brand new J-head, which I have yet use but plan on using it for ABS filament. I am currently upgrading my printer for ABS support.it a brand new all metal hotend with 0.3 nozzle, I think it can be fixed by changing the heater block with a proper design, like those Mk7 heater block like this one, http://www.aliexpress.com/item/5pcs-lot-Ma...1887070373.html but since it still CNY ordering some from ebay will take forever to ship - nozzle and cold end have 1 grub screw to hold them but! it so close to melt chamber plastic leaked out of the grub screw hole! - heater cartridge seem ok but heat not spread evenly on the heater block, temp measured on cartridge are 240 but the heater block only measured 190 - thermistor location near heating cartridge it report correct temp, but when as point no 2, heater block temp have lower temp than it actual temp set on RAMPS Note: temp measured using IR thermometer and a digital multimeter The grub screw leak sounds menacing but I am up for a challenge. If you are interested, let me know by PM. |

| Change to: |  0.0297sec 0.0297sec

0.31 0.31

6 queries 6 queries

GZIP Disabled GZIP Disabled

Time is now: 3rd December 2025 - 07:03 AM |