QUOTE(4n5 Workshop @ Jun 15 2010, 02:01 PM)

Nope, I would not say the contractor is doing a hentam job however it is a practice in the industry due to "work efficiency"

the contractor of TS is lousy one.....the lintol is under size, wonder got any steel bar inside!!! the hook at the beam also too short, the link for beam is too far C/C, column bar not proper terminated, and most of all... cast the concrete half way to leave a cold joint (weak point) to the already lousy design beam.

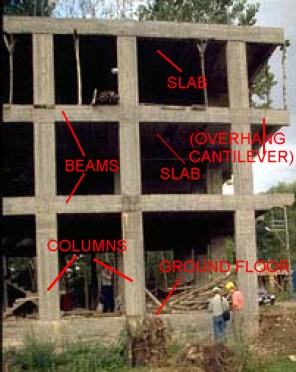

its normal practice for those renovation contractor to build the wall 1st then beam on brick wall, as i said before, to save some timber support/ scaffolding & claim the payment fast, this method is acceptable and the load from roof will distribute to the beam then the column, then foundation, provided they have design/ build the beam with sufficient reinforcement bar/ link/ width/ depth, after the beam casted & mature, it will strong/ more than enough to withstand the load and transfer it to column, those brick wall laid underneath r only temporary support the beam & will act as infill to the structure frame.

QUOTE

Technically speaking, we use 4 Y12R (iron bar) to work as a concrete beam core (bone structure) So an iron bar comes in a standard size of 12ft.

Understanding that an iron bar is 12ft but the given site is 25ft (assumption) which means we have to link 2 iron bars horizontally to form a perfect bone structure and we still have a 1ft gap. So, here comes the gimmicks of the contractor by adjusting the beam position to leave a 6 inches gap and by "abusing" the Load bearing wall theory, it does help to explain why the brick-wall does not attach to the column.

If the upper floor will not be occupied or it is just roof structure, I could compromise with it.

4 Y12R

don't quite understand how to provide the bar........

it should be in this format : 4Y12 R6-125 --- mean 4 pcs of main bar(Y / T = high tense) size 12mm dia , with link of 6mm (R= round bar) at 125mm spacing.

and all standard steel bar come in 12m length = 40 ft

NOT 12ft, if any span of the beam/ column greater than the steel bar length/ the engineer design the beam/ column with difference size of bar, you need to over lap the bar, then there is a minimum lap length of

X time of bar diameter( normally 37D-47D for column, 40D-50D for beam depends on the location of the lap & the concrete's grade).

correct me if i'm wrong

and any C&S engineer here can give some comment

Jun 8 2010, 08:23 PM, updated 16y ago

Jun 8 2010, 08:23 PM, updated 16y ago

Quote

Quote

0.0215sec

0.0215sec

1.07

1.07

5 queries

5 queries

GZIP Disabled

GZIP Disabled